Radioactive isotope neutron source and preparation method thereof

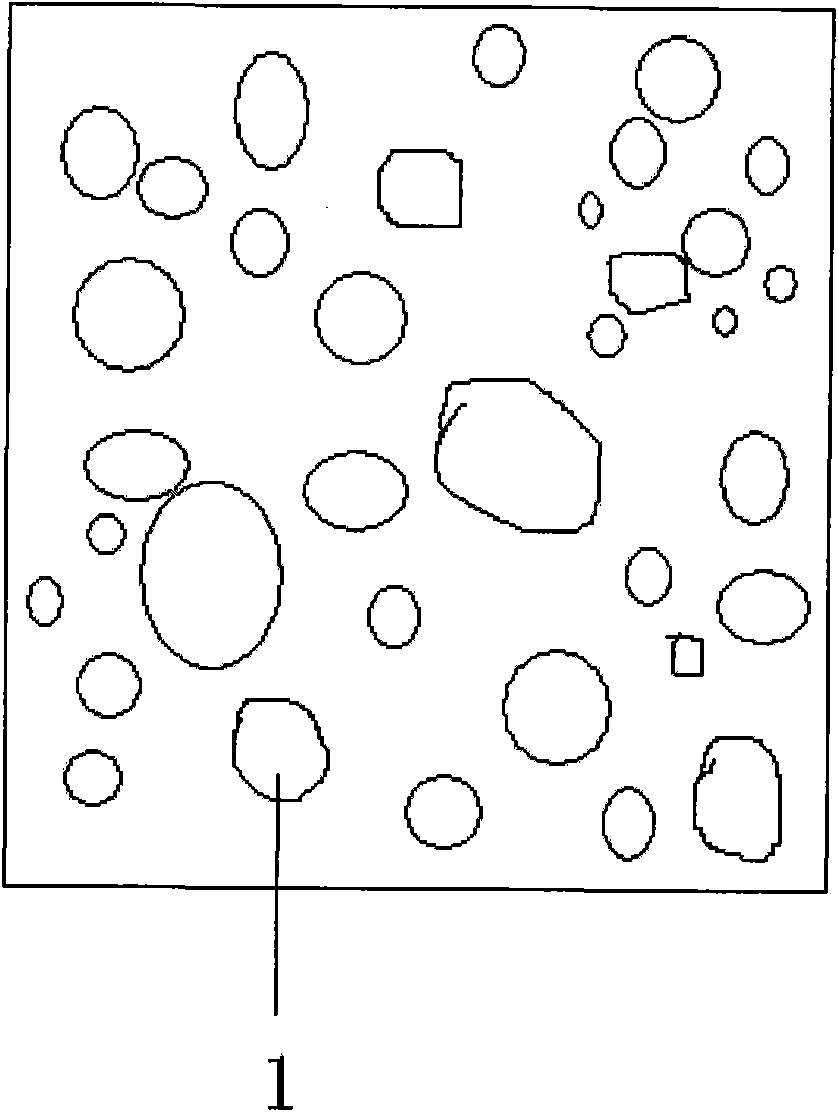

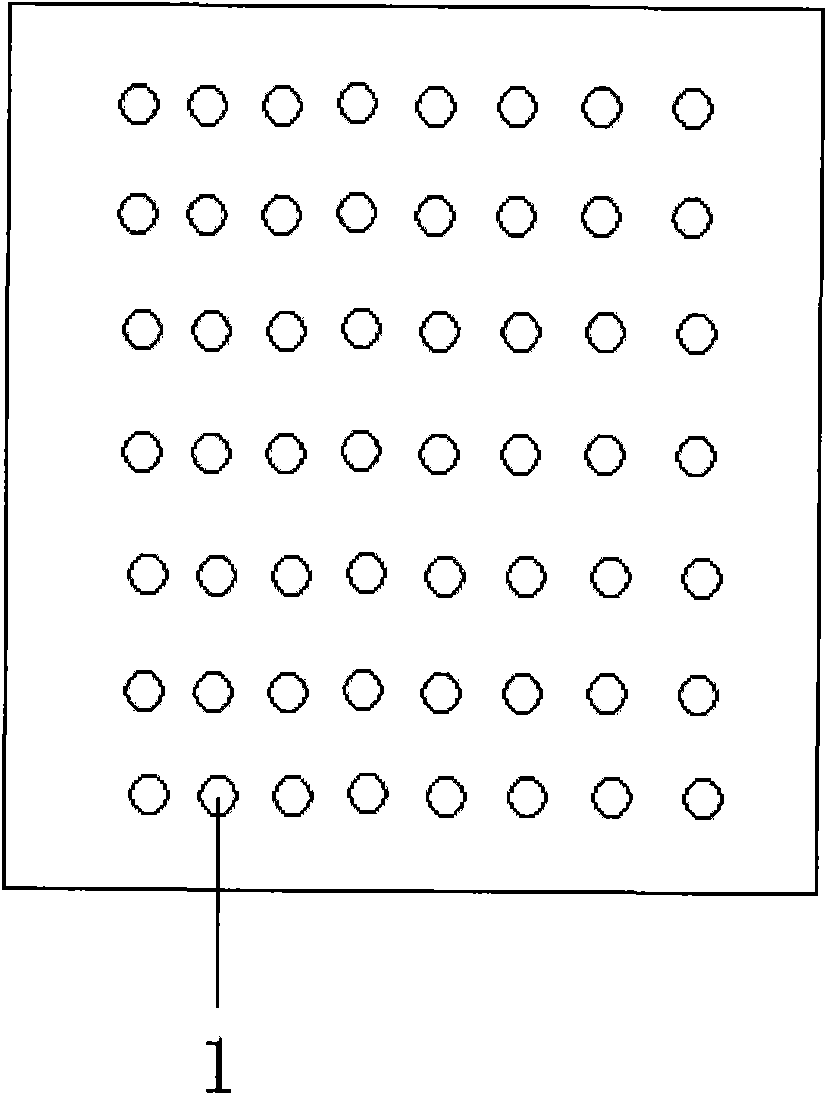

A radioactive isotope and neutron source technology, applied in the field of radioisotope neutron source, can solve the problems of metal beryllium particle distribution disorder, uneven neutron output, harm to human health, etc., to reduce radioactive pollution and achieve uniform and stable neutron output , the effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

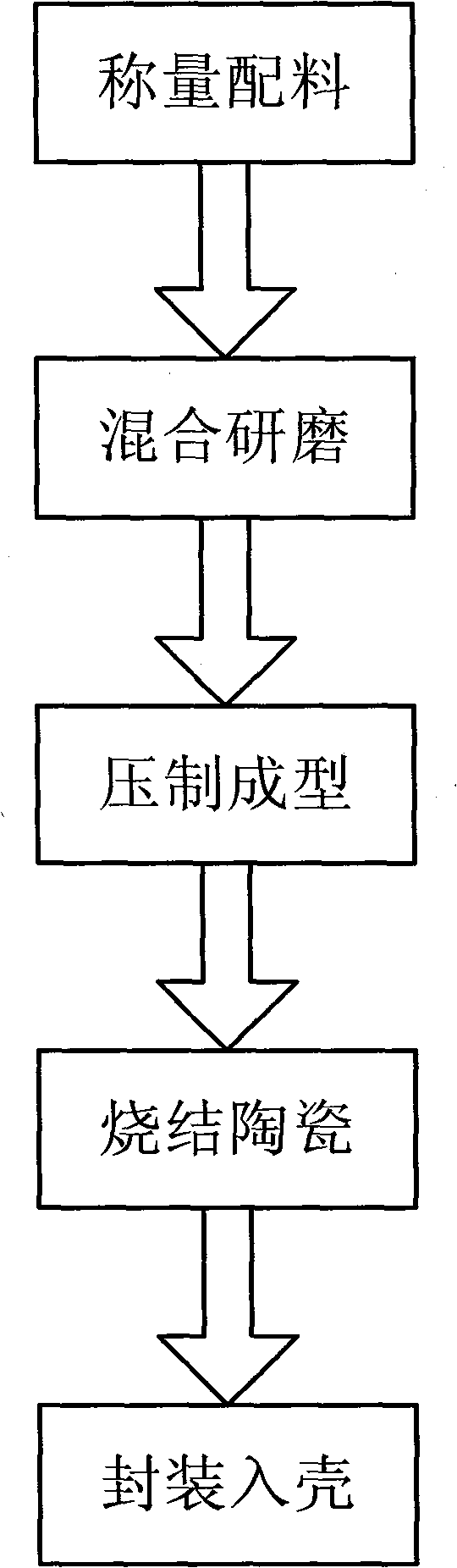

[0026] Embodiment 1 makes 100 milliju Am / Be ceramic neutron source

[0027] 1) Weigh out americium oxide (AmO 2 ) powder 33.33 milligrams, 333.33 milligrams of metal beryllium (Be) powder of 100nm grain size are standby;

[0028] 2) Put the above AmO in an airtight container 2 The powder is mixed with Be powder;

[0029] 3) After the stirring is completed, the material is placed in a closed environment for 3 hours;

[0030] 4) Put the 3) product into an agate ball mill for mixing and ball milling for 10 hours, and the particle size of the material after ball milling is 100nm;

[0031] 5) Use a hydraulic press and cooperate with a steel mold to select the shape according to the demand to press the material into the source core of the required shape;

[0032] 6) Put the pressed source core into a horse boiling furnace and burn it at 100°C for 1 hour;

[0033] 7) Adjust the temperature of the horse boiling furnace to 400°C and burn for 2 hours;

[0034] 8) Adjust the temper...

Embodiment 2

[0038] Embodiment 2 makes 100 milliju Am / Be ceramic neutron source

[0039] 1) Weigh out americium oxide (AmO 2 ) powder 33.33 mg, metal beryllium (Be) powder 333.33 mg of 100nm particle size, and 3.67 mg of flux titanium nitrate (Ti(NO 3 ) 2 )spare;

[0040] 2) Put the above AmO in an airtight container 2 The powder is mixed with Be powder;

[0041] 3) Add the above Ti(NO 3 ) 2 , stir to make it fully mixed;

[0042] 4) After the stirring is completed, the material is placed in a closed environment for 3 hours;

[0043] 5) Put the 4) product into an agate ball mill for mixing and ball milling for 10 hours, and the particle size of the material after ball milling is 100nm;

[0044] 6) add binder stearic acid in the material after ball milling, its weight is 3% of material gross weight after ball milling, constantly stir until mixing;

[0045] 7) Use a hydraulic press and cooperate with a steel mold to select the shape according to the demand to press the material into...

Embodiment 3

[0052] Embodiment 3 makes the Am / Be ceramic neutron source of 100 mCi

[0053] In this embodiment, except for the weight of Be powder, the particle size of Be powder, the storage time in a closed environment, the time of ball milling, the particle size of the material after ball milling, and the ceramic sintering time, the rest of the operating steps and operating conditions are the same as in Example 2. In this embodiment, the weight of Be powder is 199.98 mg, the particle size is 150 nm, placed in a closed environment for 3.5 hours, and the ball milling time is 11 hours. After ball milling, the particle size of the material is 150 nm. The operation of sintering the pressed source core is as follows:

[0054] 100°C 1.5 hours

[0055] 400°C 2.5 hours

[0056]800℃ for 3 hours

[0057] 1000°C for 1.5 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com