Method and device for attaching silicon nano particle film to surface of silicon solar cell

A silicon nanoparticle, silicon solar cell technology, applied in nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of reducing the cost of silicon solar cells, low yield of silicon nanoparticle, unsuitable for industrial production, etc. Low, efficient, easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

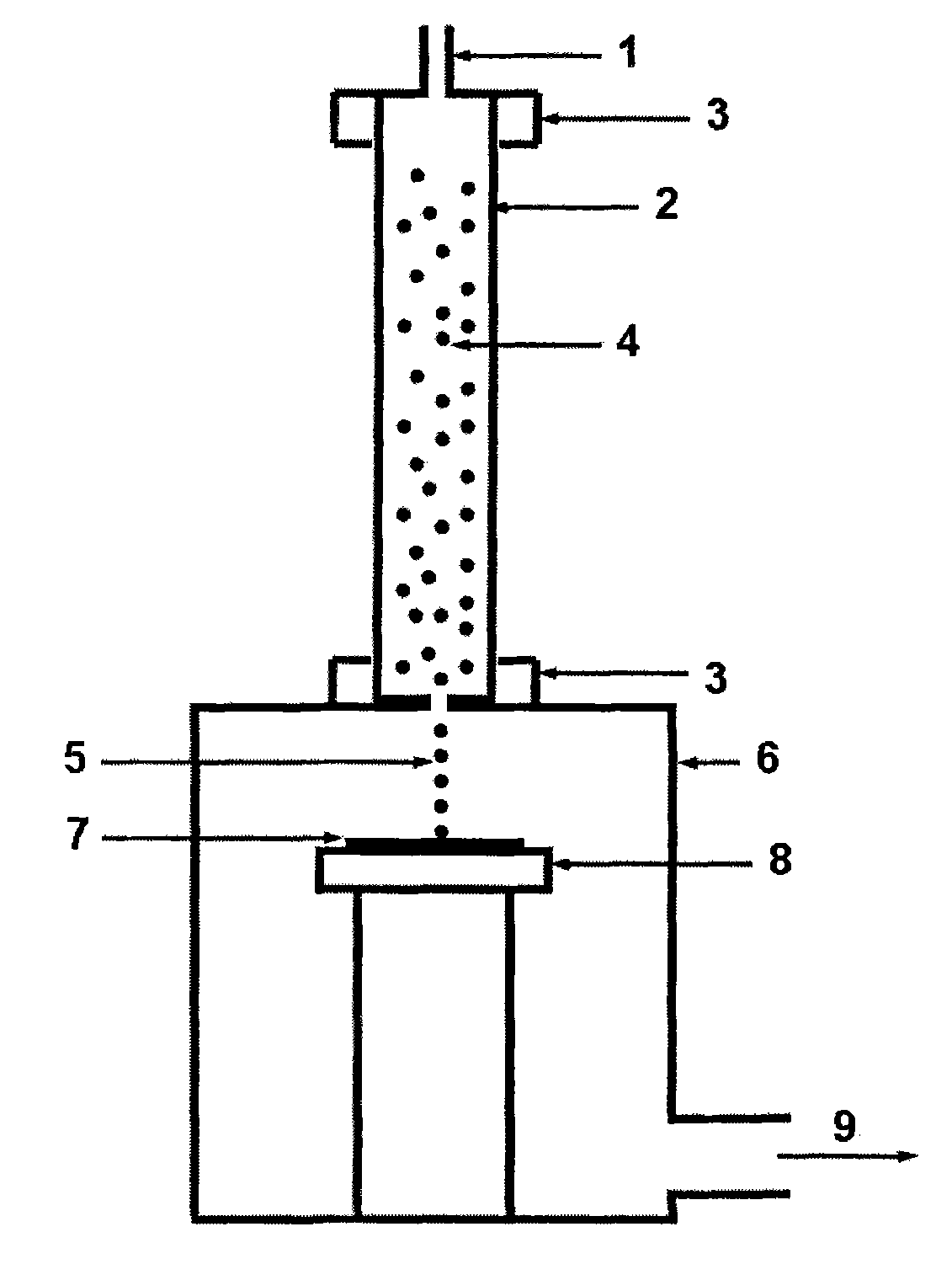

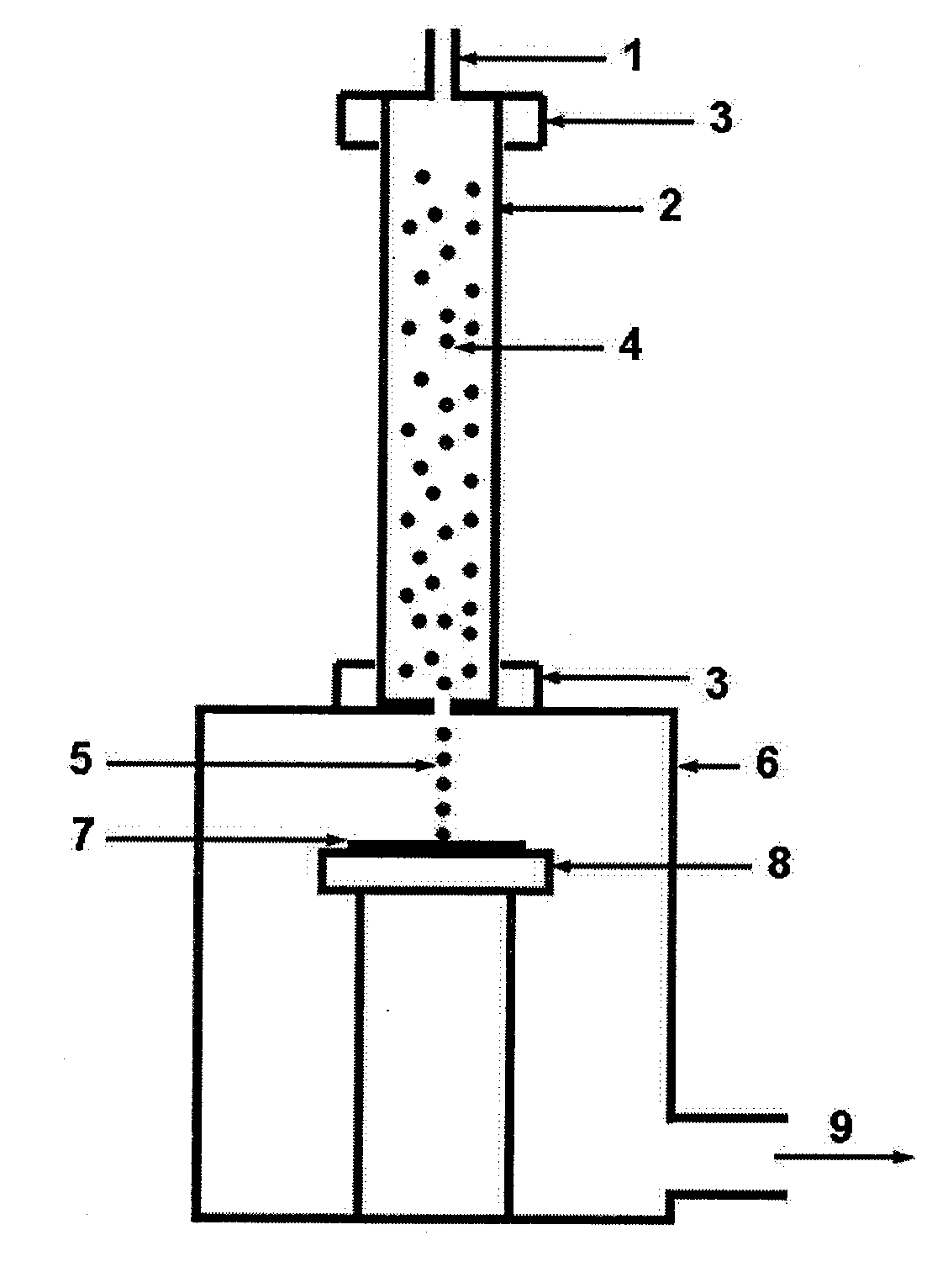

[0027] Such as figure 1 As shown, the device of the present invention for attaching a silicon nanoparticle film on the surface of a silicon solar cell includes a raw material chamber for preparing silicon nanoparticles and a film forming chamber 6 for placing a silicon solar cell. The raw material chamber is provided with an air inlet pipeline The tubular plasma chamber 2 (quartz tube) of 1, the intake pipeline 1 and the plasma chamber 2 are connected to each other through stainless steel connectors 3.

[0028] A high-frequency electromagnetic field emission device (not shown in the figure) is arranged on the periphery of the plasma chamber 2, so that the raw material gas entering the plasma chamber 2 is excited to generate silicon nanoparticles 4.

[0029] The plasma chamber 2 has an injection hole communicating with the film-forming chamber 6, the bottom of the film-forming chamber 6 is provided with a vacuum pipeline 9 for connecting to a vacuum system, and the film-forming...

Embodiment 2

[0034]Using the device of Embodiment 1, silane, argon and hydrogen are mixed and then enter the plasma chamber 2 through the inlet pipe 1 . The mixed gas forms a plasma under the excitation of a 13.56MHz radio frequency power supply, and silicon nanoparticles 4 are generated in the plasma, with an average size of 5.3nm and a standard deviation of size distribution of 0.7nm. The pressure in the plasma chamber 2 is 450Pa. Silicon nanoparticles 4 enter the stainless steel film-forming chamber 6 with a pressure of 4Pa in the form of silicon nanoparticle beams 5 after passing through the injection hole (round hole) with a diameter of 2 mm at the bottom of the plasma chamber 2 .

[0035] The silicon solar cell 7 whose surface is a grid-like metal electrode and an anti-reflection layer is placed on the sample stage 8 in the film forming chamber 6 . The vacuum of the whole system is achieved by vacuum pumping. The vacuum pump communicates with the film forming chamber 6 through a va...

Embodiment 3

[0038] Using the device of Embodiment 1, silane, argon and hydrogen are mixed and then enter the plasma chamber 2 through the inlet pipe 1 . The mixed gas forms a plasma under the excitation of a 13.56MHz radio frequency power supply, and silicon nanoparticles 4 are generated in the plasma, with an average size of 8.2nm and a standard deviation of size distribution of 1.1nm. The pressure in the plasma chamber 2 is 1060Pa. Silicon nanoparticles 4 enter the stainless steel film-forming chamber 6 with a pressure of 0.3Pa in the form of silicon nanoparticle beams 5 after passing through the injection hole (round hole) with a diameter of 1 mm at the bottom of the plasma chamber 2 .

[0039] The silicon solar cell 7 whose surface is a grid-like metal electrode and an anti-reflection layer is placed on the sample stage 8 in the film forming chamber 6 . The vacuum of the whole system is achieved by vacuum pumping. The vacuum pump communicates with the film forming chamber 6 through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com