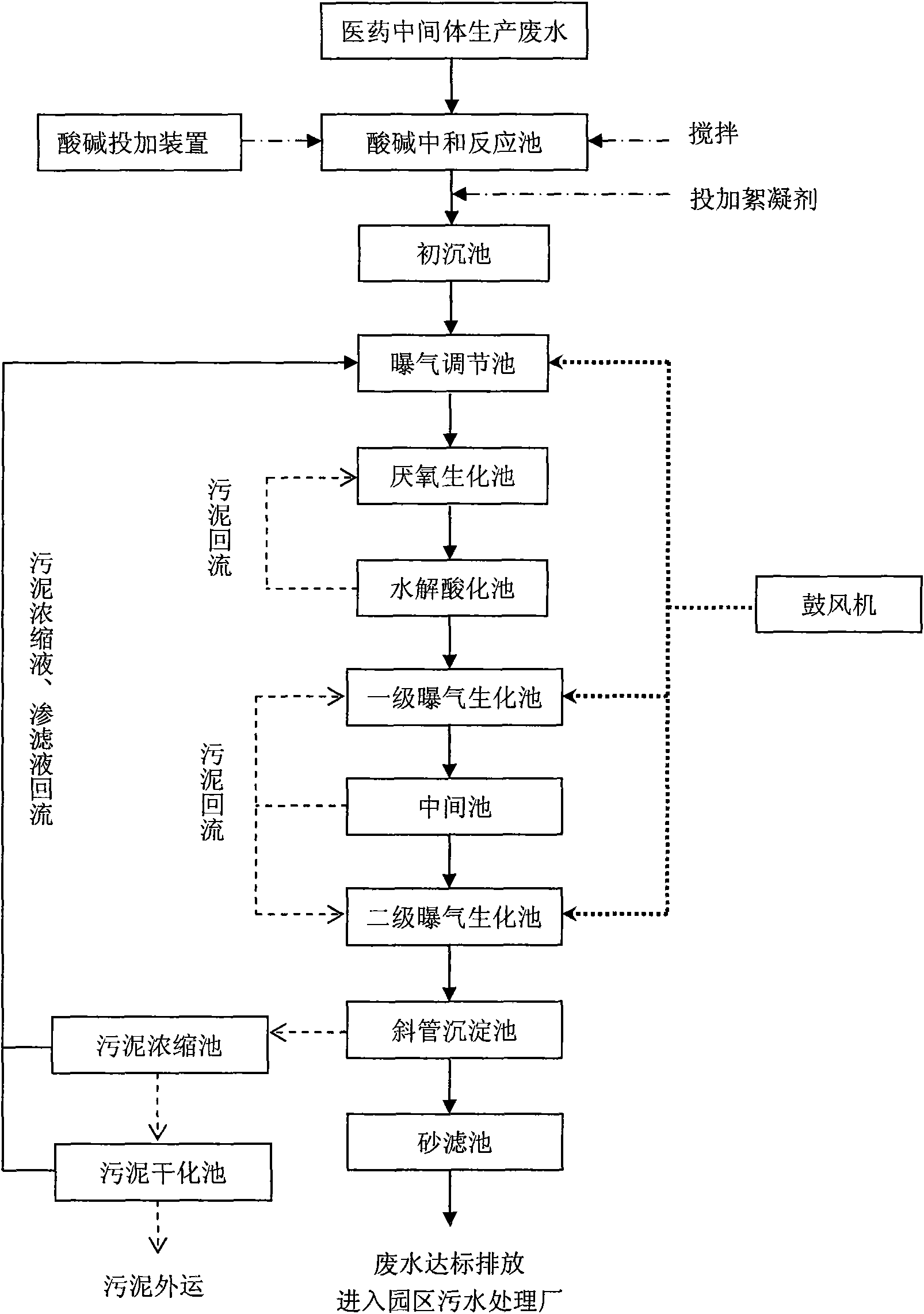

Treatment process for medical intermediate production waste water

A treatment method and technology for producing waste water, applied in natural water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as large impact load, pollution, complex composition, etc., and reduce power consumption , good treatment effect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The wastewater comes from Anhui Qianhui Pharmaceutical Co., Ltd. The wastewater contains raw materials CP, intermediates SP and POTA, as well as a large amount of acid and alkali components. The waste water enters the acid-base neutralization pool from the collection system by gravity, and the pH is adjusted by mixing the waste water. If necessary, acid and alkali are added to adjust the pH value to 6-8, so that the waste water is conducive to subsequent treatment and reduces the impact on subsequent structures and equipment. The impact, the residence time is 2h. After acid-base neutralization and adjustment, the wastewater flows into the primary settling tank by itself, and polyaluminum sulfate flocculant is added before entering the primary settling tank to improve the flocculation effect and settling performance of suspended solids and water-insoluble pollutants in the wastewater. The settled wastewater flows into the aeration adjustment tank, which is equipped with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com