Sulphuric acid dew point monitoring analyzer

A sulfuric acid dew point and analyzer technology, applied in the direction of material water content, etc., can solve the problems of increased production and maintenance costs, increased operating costs, acid soot emissions, etc., and achieves the effect of reducing the weight of the instrument, convenient operation and maintenance, and easy portability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to enable those of ordinary skill in the art to clearly understand the technical solutions of the present invention, the present invention will now be further described with reference to the accompanying drawings:

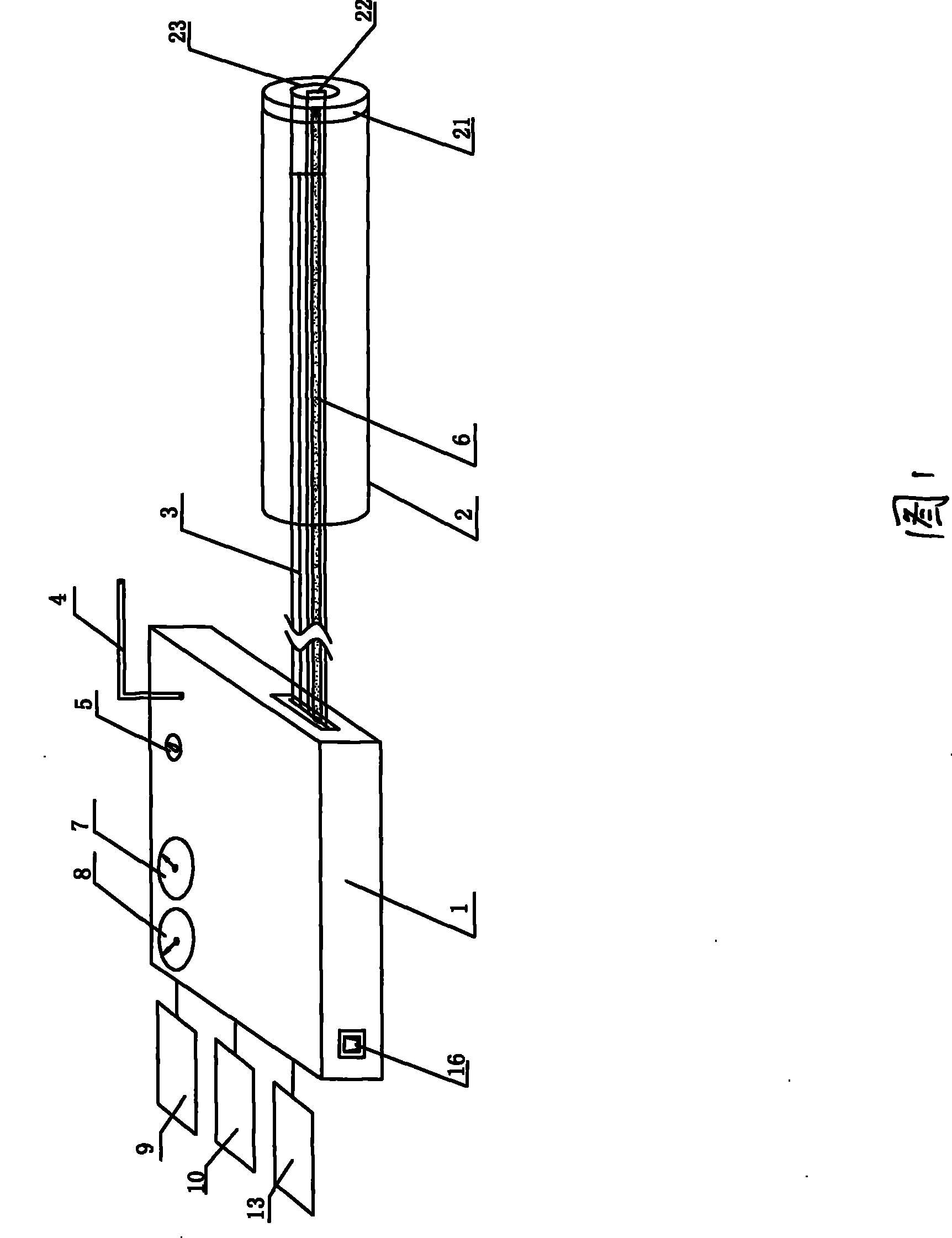

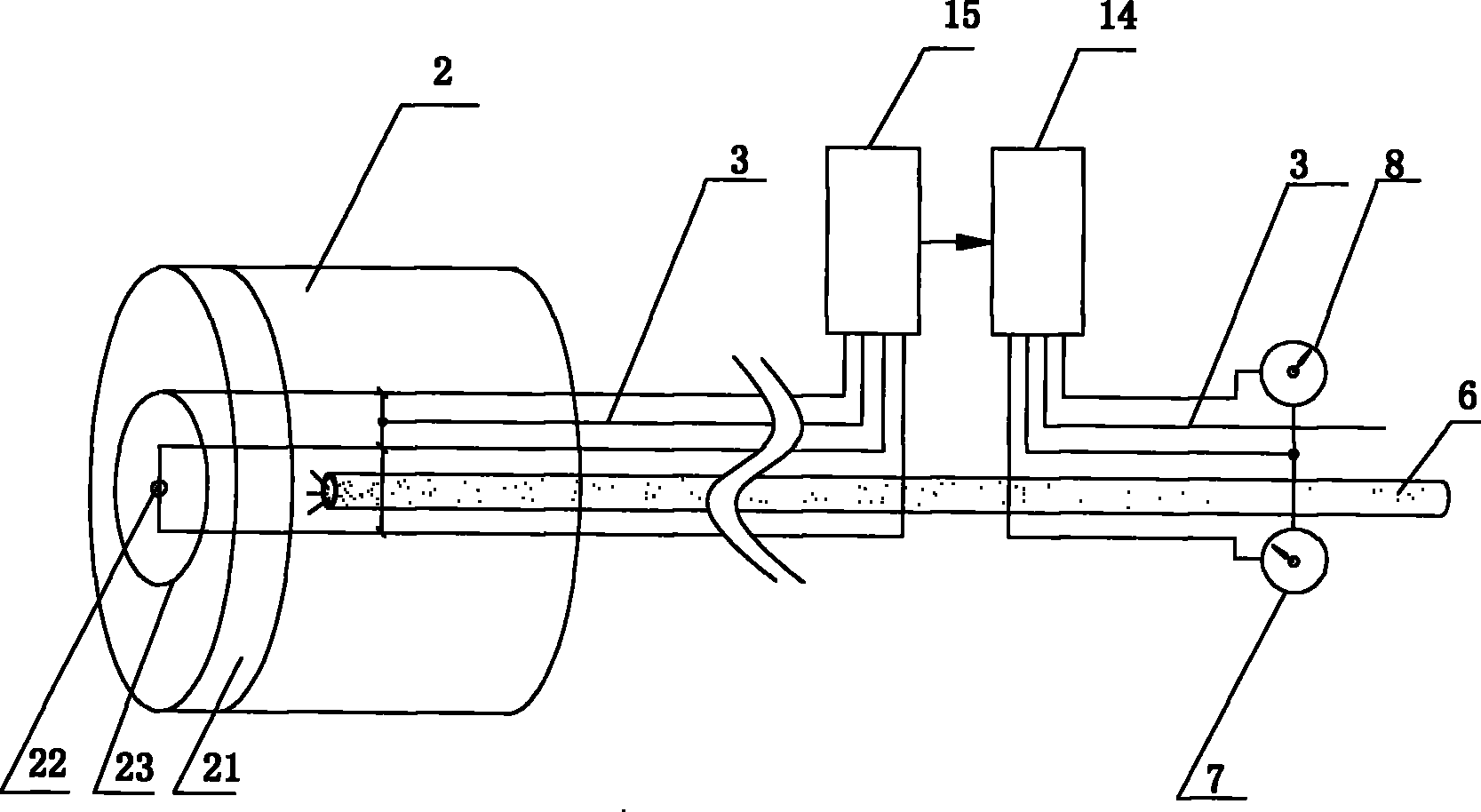

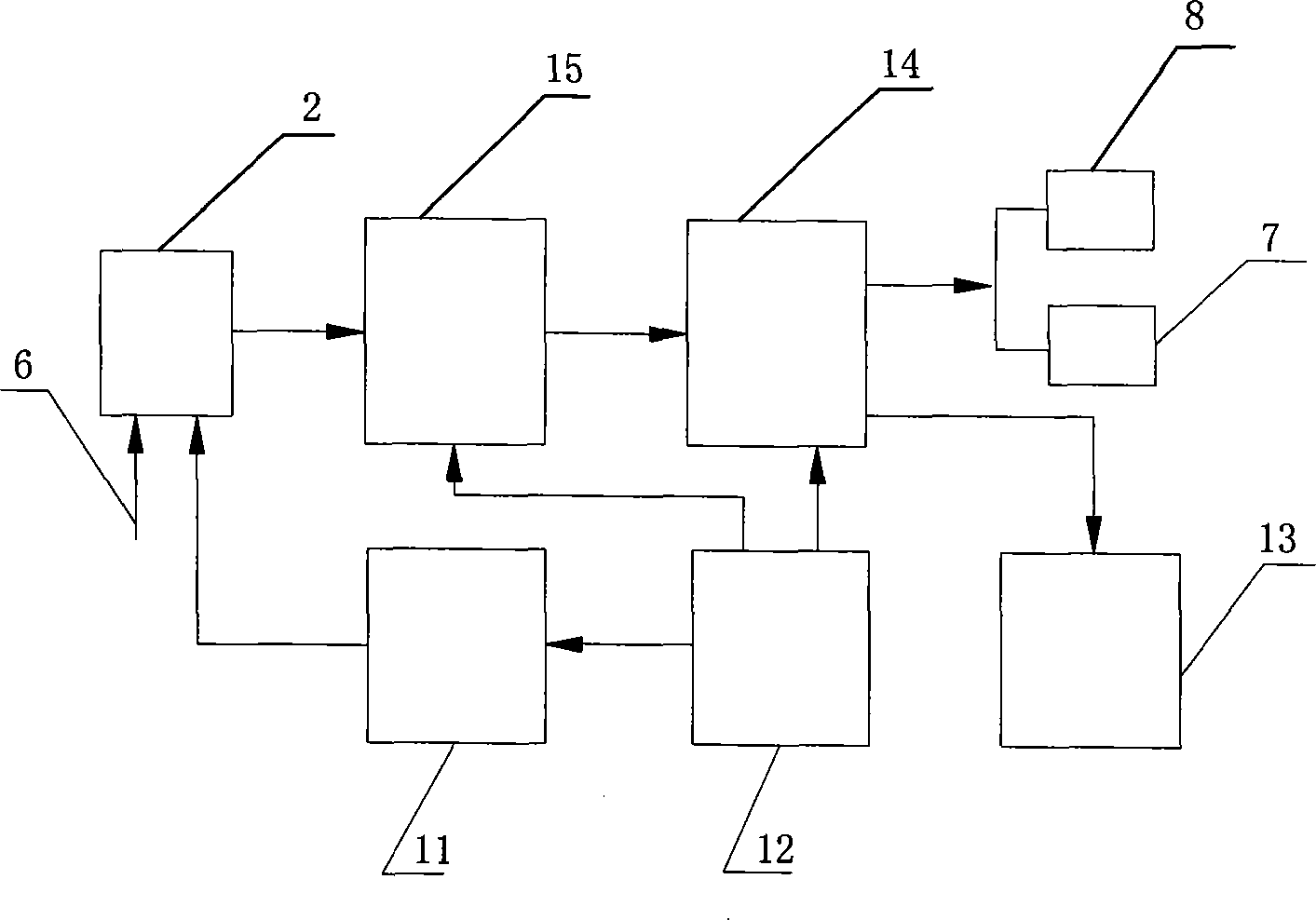

[0015] A sulfuric acid dew point monitoring analyzer, such as figure 1 , figure 2 and image 3 As shown, it includes a main control board 14, a signal amplifying unit 15, a frequency generator 11, and a main power supply 12 arranged in the main box 1. The signal amplifying unit 15 can realize A / D conversion and is connected to the sensor 2 through the signal line 3 The front end of the sensor 2 is provided with a housing 21 encapsulated by temperature-resistant glass, a platinum ring 23 is provided in the middle, a platinum rhodium-platinum platinum thermocouple 22 is provided in the platinum ring 23, a signal amplification unit 15 and a main control unit with windows RM operating system The board 14 is connected to realize a friendly user interaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com