Solar photovoltaic component welding process

A technology of solar photovoltaic and welding technology, which is applied in the field of solar photovoltaic, can solve problems such as short circuits, and achieve the effects of increasing service life, improving resistance to distortion, and reducing bridging stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation of the present invention.

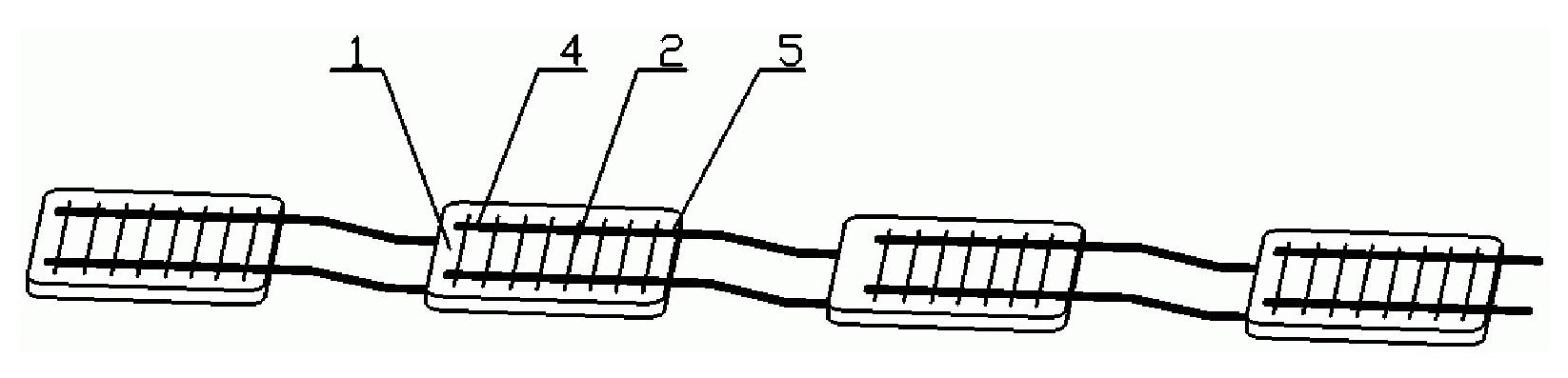

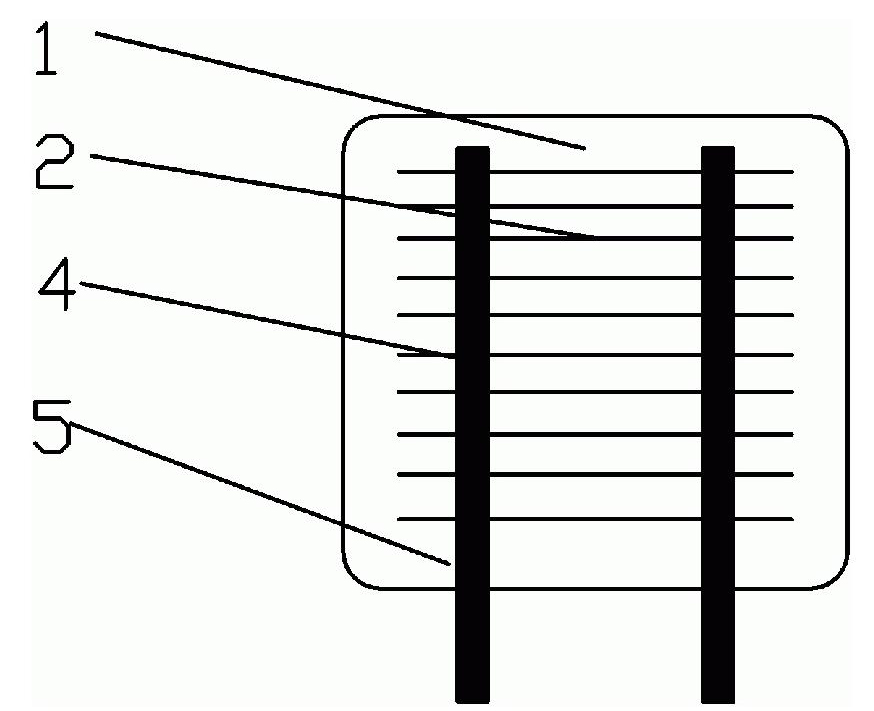

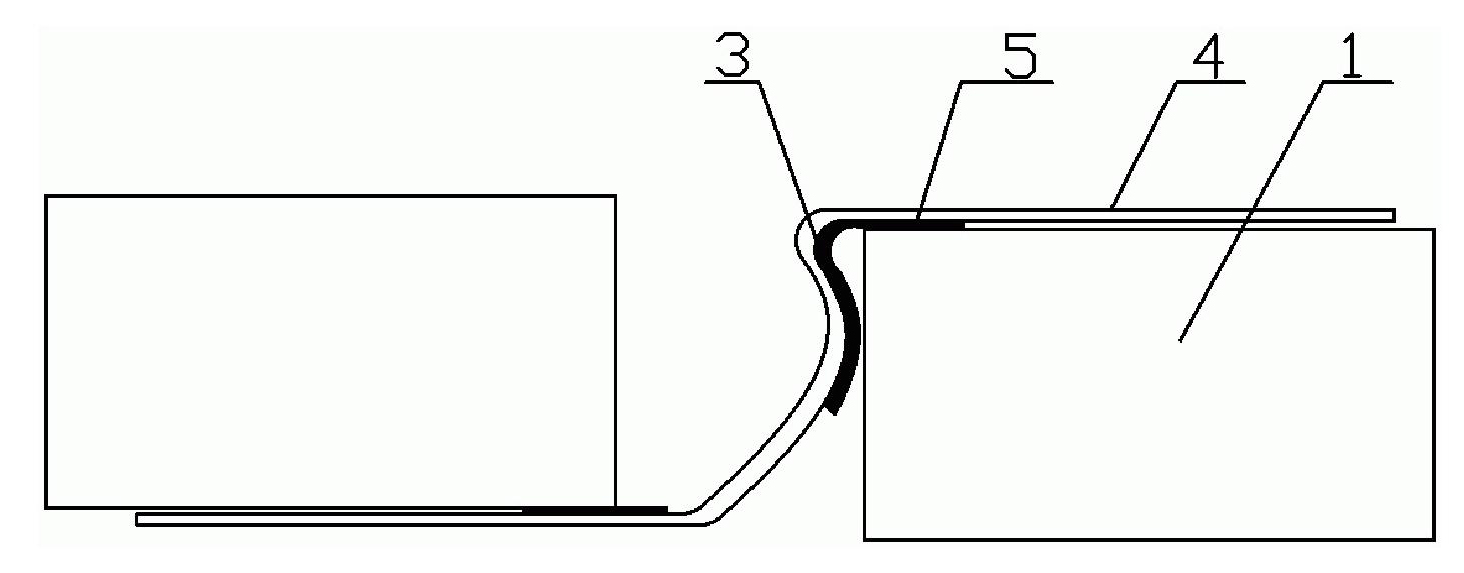

[0024] Example. Solar photovoltaic modules, constituted as figure 1 , figure 2 with image 3 , including a group of solar cells 1, each solar cell 1 surface (including the front and back) is provided with a main grid 2 (see figure 2 ); the front of the solar cell and the back of the adjacent solar cell are welded and connected by the interconnection bar 4; at the end of the solar cell 1, there is a welding gap area 5 between the lead-out line of the interconnection bar and the solar cell (see image 3 ). The length of the welding void area 5 is preferably 5-10 mm.

[0025] The welding process of the aforementioned solar photovoltaic modules comprises the following steps:

[0026] a. Weld the front side first (ie image 3 above); preheat the soldering station a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com