Process for treating antibiotic pharmaceutical wastewater

A technology for treating process and pharmaceutical wastewater, applied in water/sewage multi-stage treatment, oxidized water/sewage treatment, illumination water/sewage treatment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

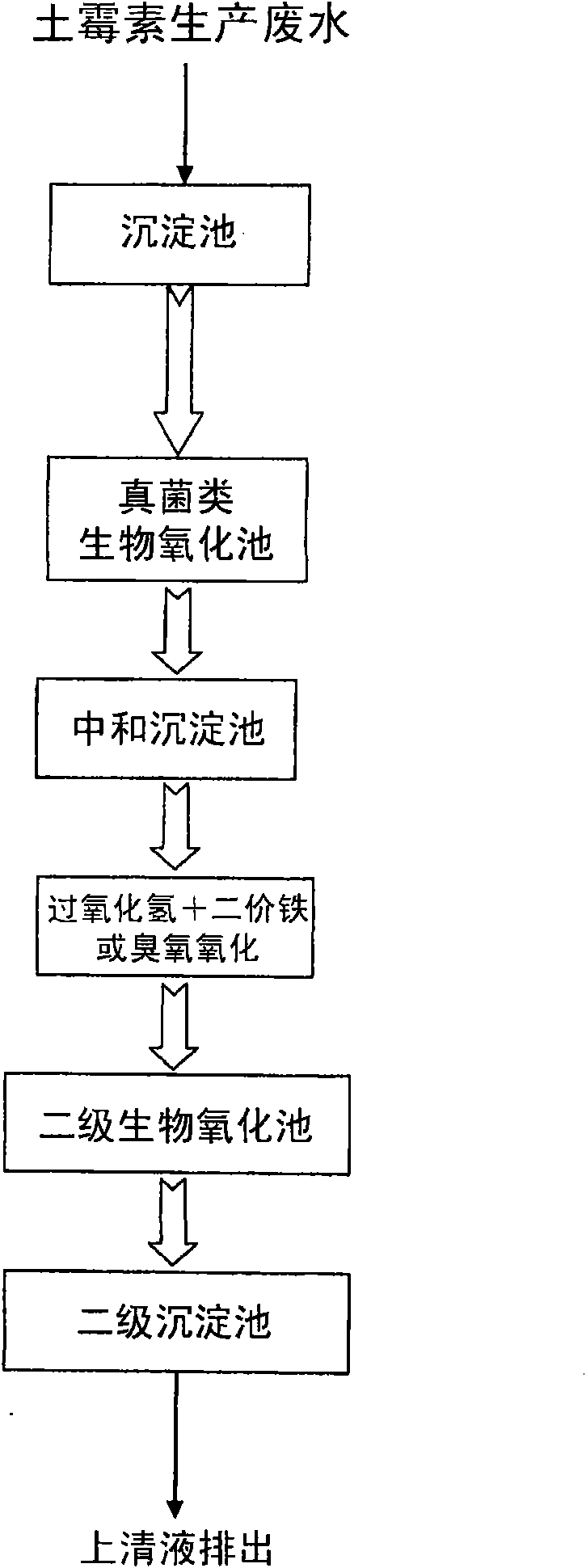

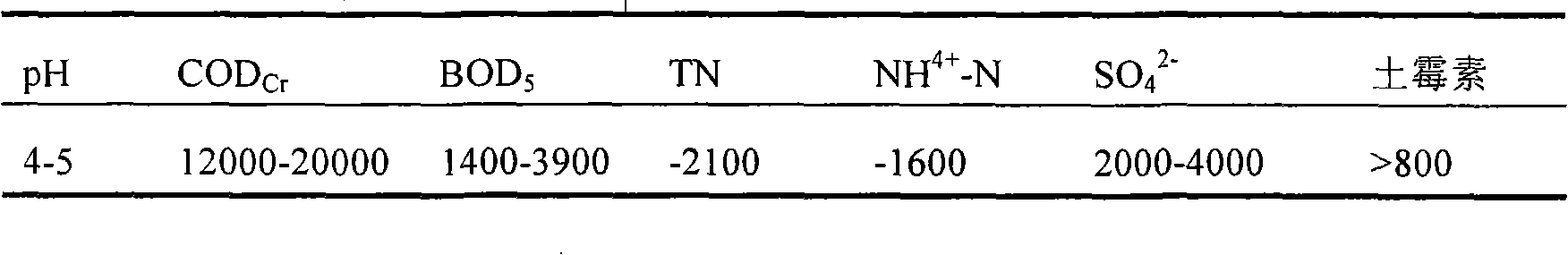

[0032] The production wastewater of a domestic oxytetracycline production plant was taken for testing. The raw water quality is shown in Table 2: It can be seen that the sewage has high COD, ammonia nitrogen, sulfate radical and low biodegradability. The waste water is treated by adopting the treatment process for pharmaceutical waste water provided by the invention. First, the residual mycelium is separated by sedimentation in the sedimentation tank. After precipitation, the wastewater is pumped to the first-level biological oxidation tank. The water retention time in this tank is 24 hours. Under the action of mold, part of the organic matter in the sewage is decomposed and oxidized; The effluent stays in the primary sedimentation tank for 8 hours for solid-liquid separation; the separated supernatant enters the Fenton reaction tank, adjusts the pH to 3.5, and the amount of hydrogen peroxide is 1-10% of the concentration of oxytetracycline in the wastewater. Generally speaki...

Embodiment 2

[0038] The production wastewater of a domestic oxytetracycline production plant was taken for testing. The raw water quality is shown in Table 2: It can be seen that the sewage has high COD, ammonia nitrogen, sulfate radical and low biodegradability. The waste water is treated by adopting the treatment process for pharmaceutical waste water provided by the invention. First, the residual mycelium is separated by precipitation in the sedimentation tank. After precipitation, the wastewater is pumped to the first-level biological oxidation tank. The water retention time in this tank is 48 hours. Under the action of yeast, part of the organic matter in the sewage is decomposed and oxidized ; The effluent stays in the primary sedimentation tank for 8 hours for solid-liquid separation; the separated supernatant enters the ozone reactor. Adjust the pH of the wastewater to 7, the dosage of ozone is in the range of 30-120mg / L, and the reaction time of ozone oxidation is 2 hours. Durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com