Preparation method for expansion type melamine hypophosphite fire retardant

A technology of melamine hypophosphite and melamine, applied in the direction of organic chemistry and the like, can solve the problems of flame retardant effect, many reaction by-products, complicated reaction process, etc., and achieves good compatibility, simple waste water recycling, and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

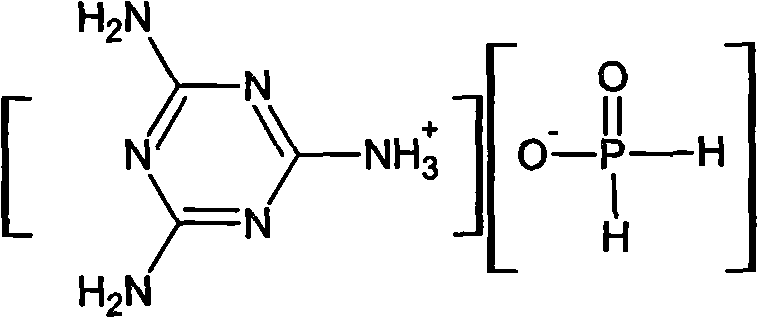

[0015] Get 126g of melamine (1mol) and 132g of hypophosphorous acid (1mol) with a concentration of 50%, add hypophosphorous acid and 1L of water into a 2000ml beaker, place in a water bath at 25°C, stir with a constant speed electric stirrer at a speed of 300r / min , Add melamine in batches and react for 2 hours. The reaction product was suction-filtered, washed with an appropriate amount of water, dried in a vacuum oven at 150° C. for 3 hours, weighed and the yield of melamine hypophosphite MHP was 170.1 g, and the reaction yield was 88.54%. The expected reaction product structure is:

[0016]

[0017] Elemental analysis (%): the main element N is 43.38 (43.75), P is 16.09 (16.15), the theoretical content is in brackets, and the structure of the synthesized product has been confirmed by infrared spectrum analysis.

Embodiment 2

[0019] Get 126g of melamine (1mol) and 132g of hypophosphorous acid (1mol) with a concentration of 50%, add hypophosphorous acid and 1L of water into a 2000ml beaker, place in a 50°C water bath, stir with a constant speed electric stirrer at a speed of 300r / min , Add melamine in batches and react for 2 hours. The reaction product was suction-filtered, washed with an appropriate amount of water, dried in a vacuum oven at 150° C. for 3 hours, weighed and the yield of melamine hypophosphite MHP was 164.9 g, and the reaction yield was 85.93%.

Embodiment 3

[0021] Get 126g of melamine (1mol) and 264g of hypophosphorous acid (2mol) with a concentration of 50%. Add hypophosphorous acid and 1L of water into a 2000ml beaker, place in a water bath at 25°C, and stir with a constant speed electric stirrer at a speed of 300r / min , Add melamine in batches and react for 2 hours. The reaction product was suction-filtered, washed with an appropriate amount of water, dried in a vacuum oven at 150° C. for 3 hours, weighed and the yield of melamine hypophosphite MHP was 213.6 g, and the reaction yield was 82.79%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com