polarized light emitting diode

A light-emitting diode, polarization technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., to achieve the effect of overall volume reduction, cost reduction, and performance optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

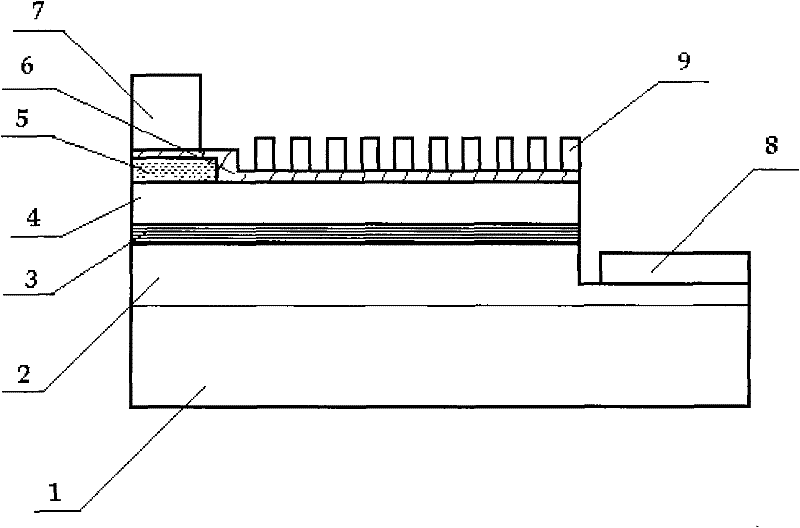

[0026] See attached figure 1 , which is a schematic cross-sectional view of the structure of a relief-type polarized light-emitting diode chip provided in this embodiment. The structure of the polarized light-emitting diode chip prepared on the surface of the III-V gallium nitride-based LED is as follows: an LED light-emitting working area is grown on the substrate material 1, including n-type GaN region 2, p-type GaN region 4 and InGaN / GaN Quantum well 3; on the p-type GaN region, there is an insulating dielectric film 5 in sequence, and the insulating medium is SiO 2 or SiN; p-type layer transparent electrode 6; p-type layer metal electrode 7 and relief metal film grating 9; and n-type layer metal electrode 8 on the n-type GaN region exposed by etching.

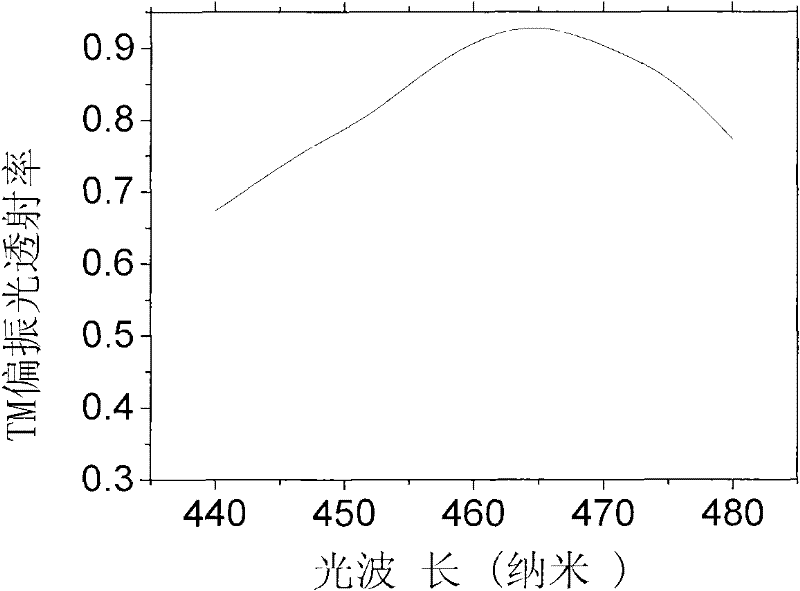

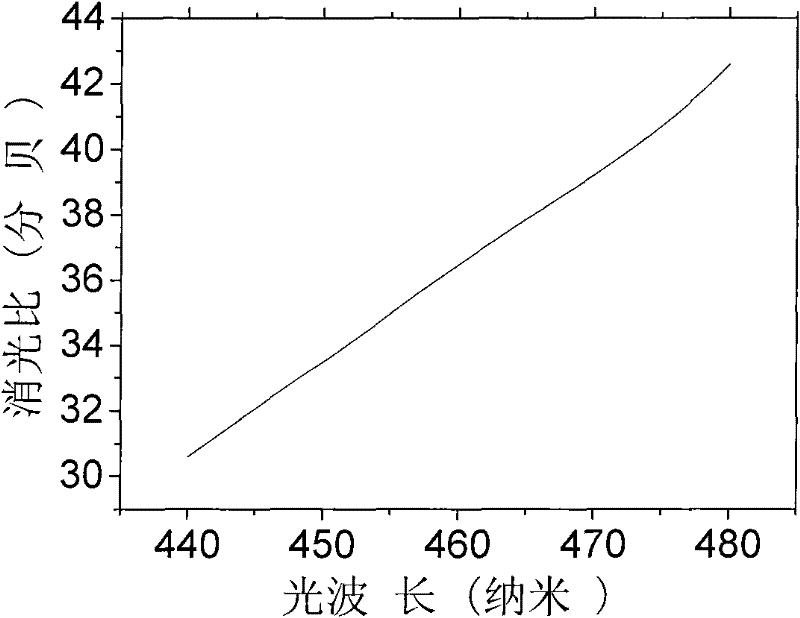

[0027] The shape, period, duty cycle, and thickness of the grating are theoretically calculated according to the specific luminous wavelength of the LED. The combination of the best polarization extinction ratio and trans...

Embodiment 2

[0037] See attached Figure 4 , which is a structural cross-sectional schematic diagram of an embedded polarized light-emitting diode chip provided in this embodiment; the embedded polarized light-emitting diode chip prepared on the surface of a III-V gallium nitride-based LED includes: substrate material 1; n-type GaN layer 2; InGaN / GaN quantum well 3; p-type GaN layer 4; SiO 2 Insulating dielectric film 5; p-type layer transparent electrode 6; p-type layer metal electrode 7; n-type layer metal electrode 8 and embedded metal GaN grating 10.

[0038] Compared with the structure of Example 1, the difference lies in that the periodic grating of this structure is prepared on the p-type layer of GaN, and the grating is formed by the concavo-convex structure of GaN.

[0039] In this embodiment, it is determined by calculation that the shape of the grating is a rectangle, the duty ratio of the grating is 0.52, the thickness of the grating is 300nm, and the period of the grating is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com