Electronic ballast for fluorescent lamp

A technology for electronic ballasts and fluorescent lamps, applied in the direction of light sources, electric light sources, electrical components, etc., can solve problems such as unsatisfactory effects, rough lamp power control, and inoperable circuits, achieving better preheating effect and shortening the process. time, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

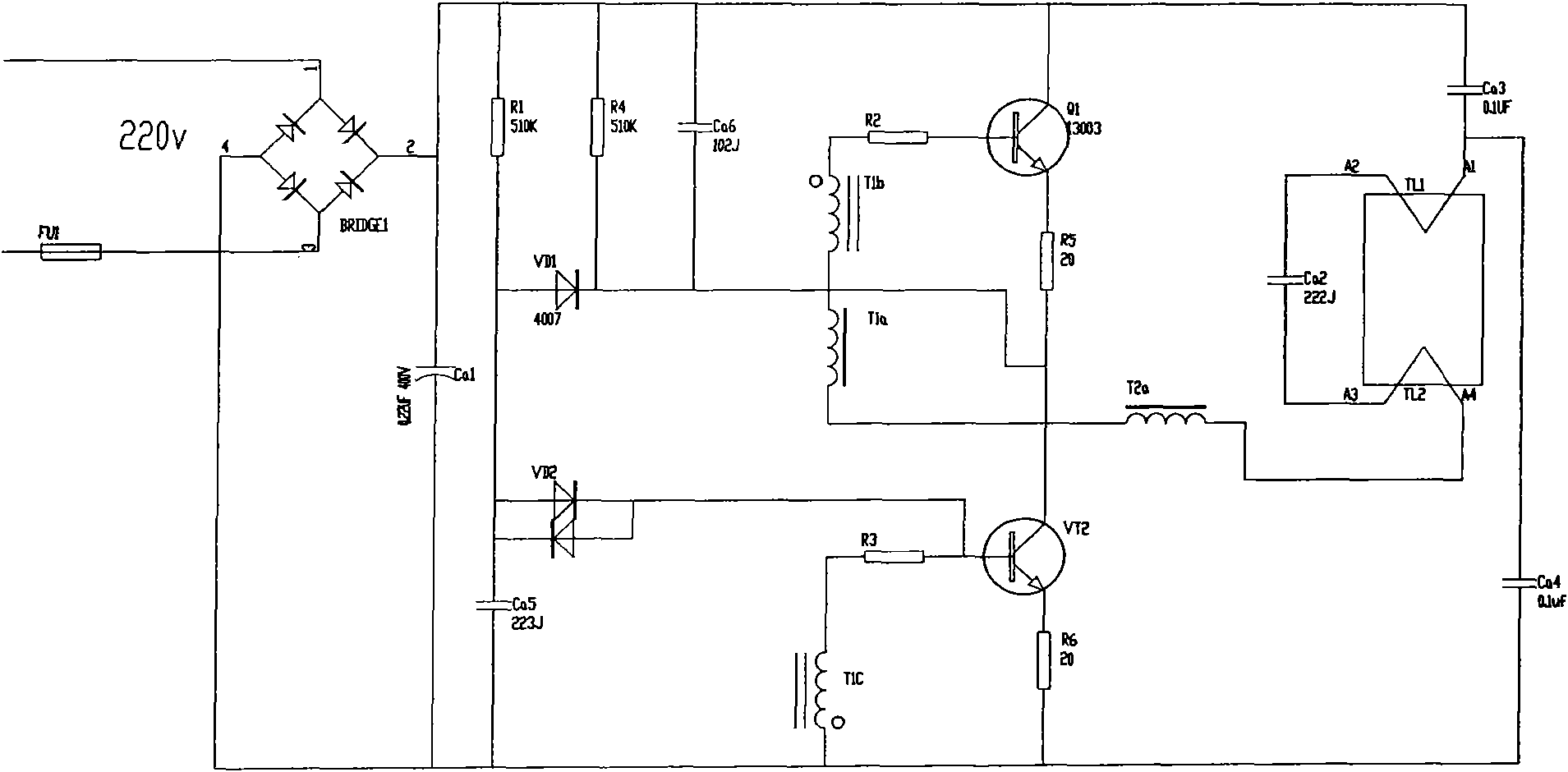

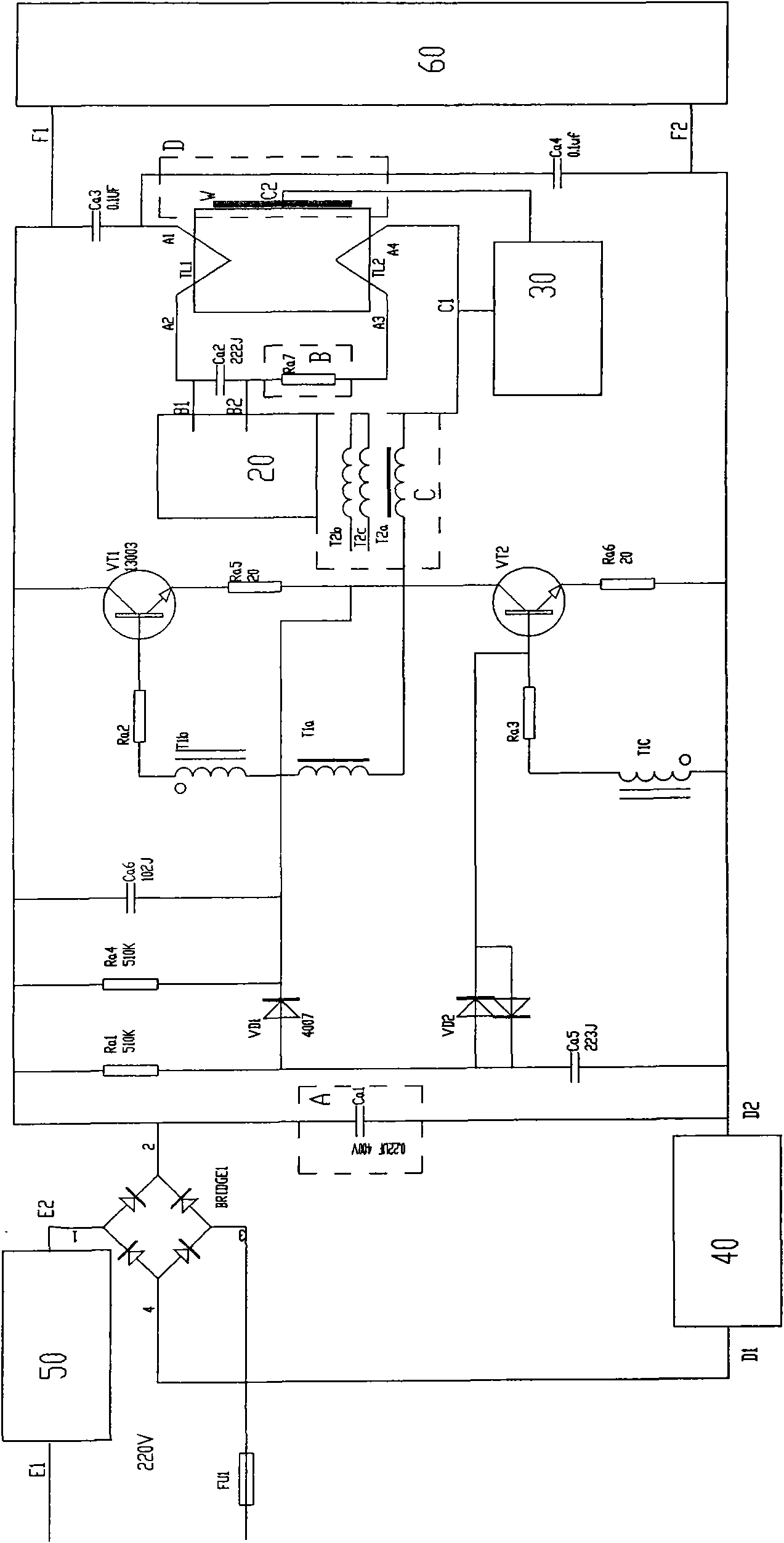

[0024] see figure 1 , is the circuit diagram of the existing typical basic half-bridge ballast. When the circuit is powered on, the resistance Ra flows through the 1 The current to the capacitance Ca 5 charging, when the capacitor Ca 5 The voltage across the two ends reaches the bidirectional trigger diode VD 2 When the trigger voltage (about 35V or so), VD 2 Avalanche breakdown, when the capacitor Ca 5 Through the switch tube VT 2 The base → emitter discharge, VT 2 is turned on due to the forward bias of the emitter junction, at VT 2 During conduction, the current path is: +VDC→Ca 3 → Tube Filament FL 1 →Ca 2 → Filament FL 2 → Ballast inductor La 1 →Ta 1 Primary coil Ta 1a →VT 2 collector → VT 2 The emitter → ground, the switch tube VT 2 The instantaneous change in collector current is Through the oscillating coil Ta 1a The two secondary windings Ta 1b and Ta 1c The corresponding induced electromotive force is generated, and the polarity of the induced el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com