Method for extracting, rectifying and separating pseudocumene and indane

A technology of partial trimethylbenzene, extraction and rectification, applied in the field of separation of chemical industry, can solve the problems affecting the development and utilization of resources, high energy consumption, etc., and achieve the effect of low production cost, low energy consumption and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

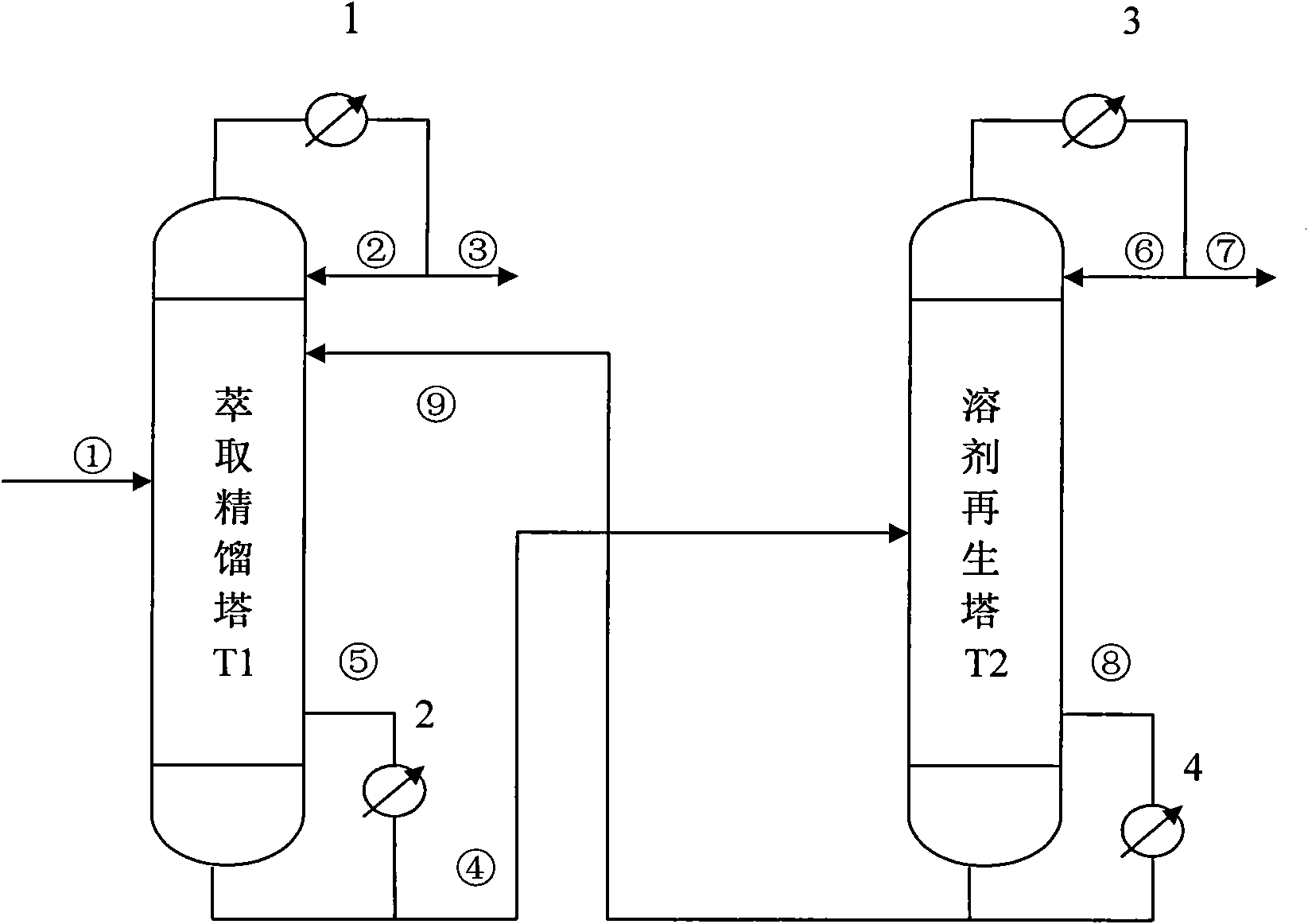

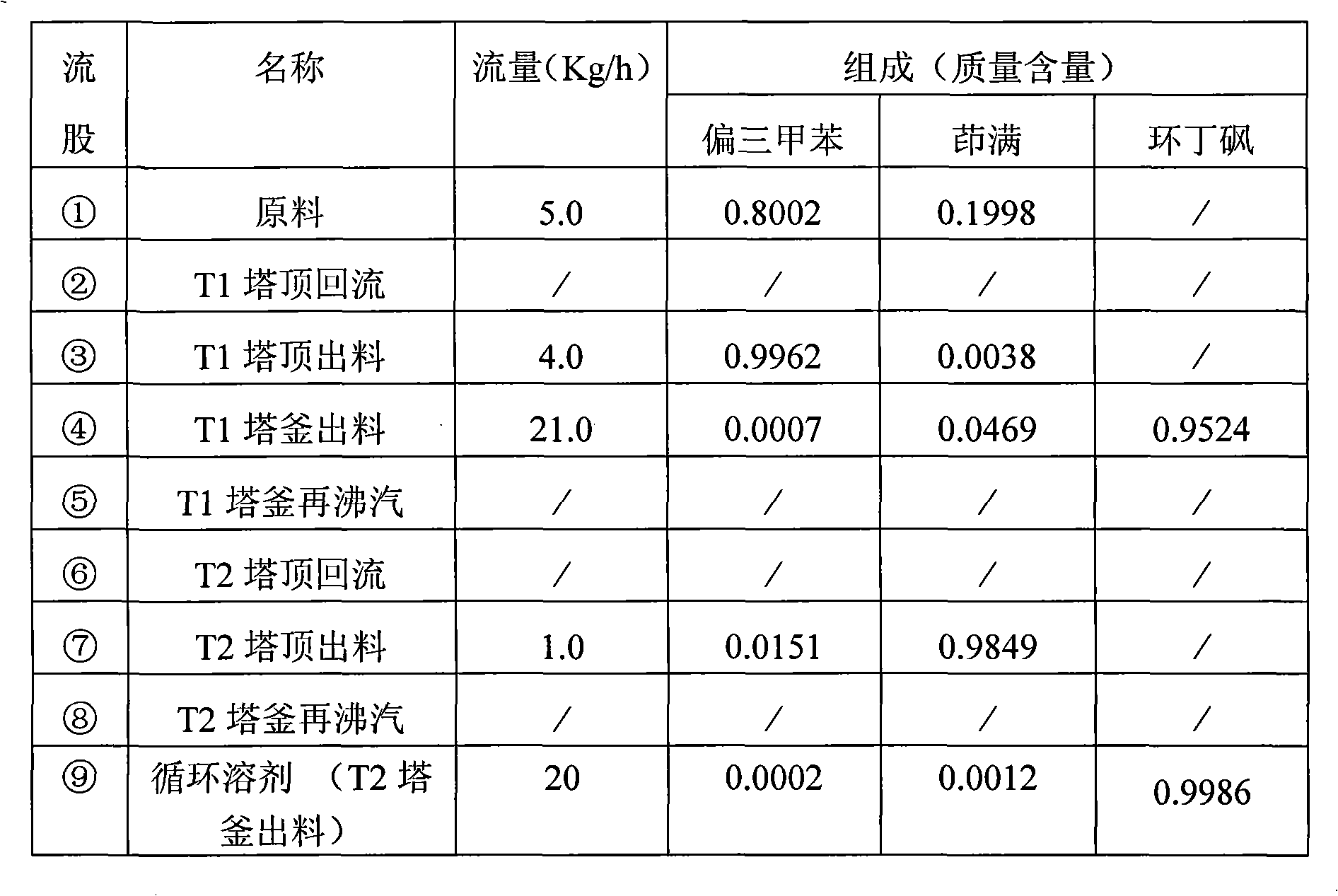

[0015] Embodiment 1, the method for extracting and rectifying separation of trimethylbenzene and indane, with reference to figure 1 Shown technological process and technological parameters shown in table 1, raw material 1. is a raw material mixture, wherein the mass content of mesitylene and indane are respectively 80%, 20%, flow rate is 5Kg / h, solvent 9. is sulfolane, and flow rate is 15Kg / h, the temperature at the top of the extractive distillation tower T1 is 168-169°C, the temperature at the bottom of the tower is 255-260°C, the reflux ratio is controlled at 4-5, the flow rate of the tower top extract ③ is 4Kg / h, and the composition is x 偏三甲苯 =0.9962,x 茚满 =0.0038, tower kettle discharge ④The flow rate is 21Kg / h, and the composition is x 环丁砜 =0.9524,x 偏三甲苯 =0.0007,x 茚满 =0.0469, this part of the output is also the feed of the solvent regeneration tower T2, the top temperature of the solvent regeneration tower T2 is 176-177°C, the temperature of the tower bottom is about ...

Embodiment 2

[0020] Embodiment 2 is substantially the same as Embodiment 1, but the mass ratio of solvent to raw material mixture is 2 / 1.

Embodiment 3

[0021] Embodiment 3 is substantially the same as Embodiment 1, but the mass ratio of solvent to raw material mixture is 4 / 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com