Polyurethane sealant and preparation method thereof

A polyurethane sealant, prepolymer technology, applied in the direction of polyurea/polyurethane adhesives, chemical instruments and methods, adhesives, etc., can solve the problem of low elongation, low body strength, affecting the application effect of one-component polyurethane sealants or ergonomics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

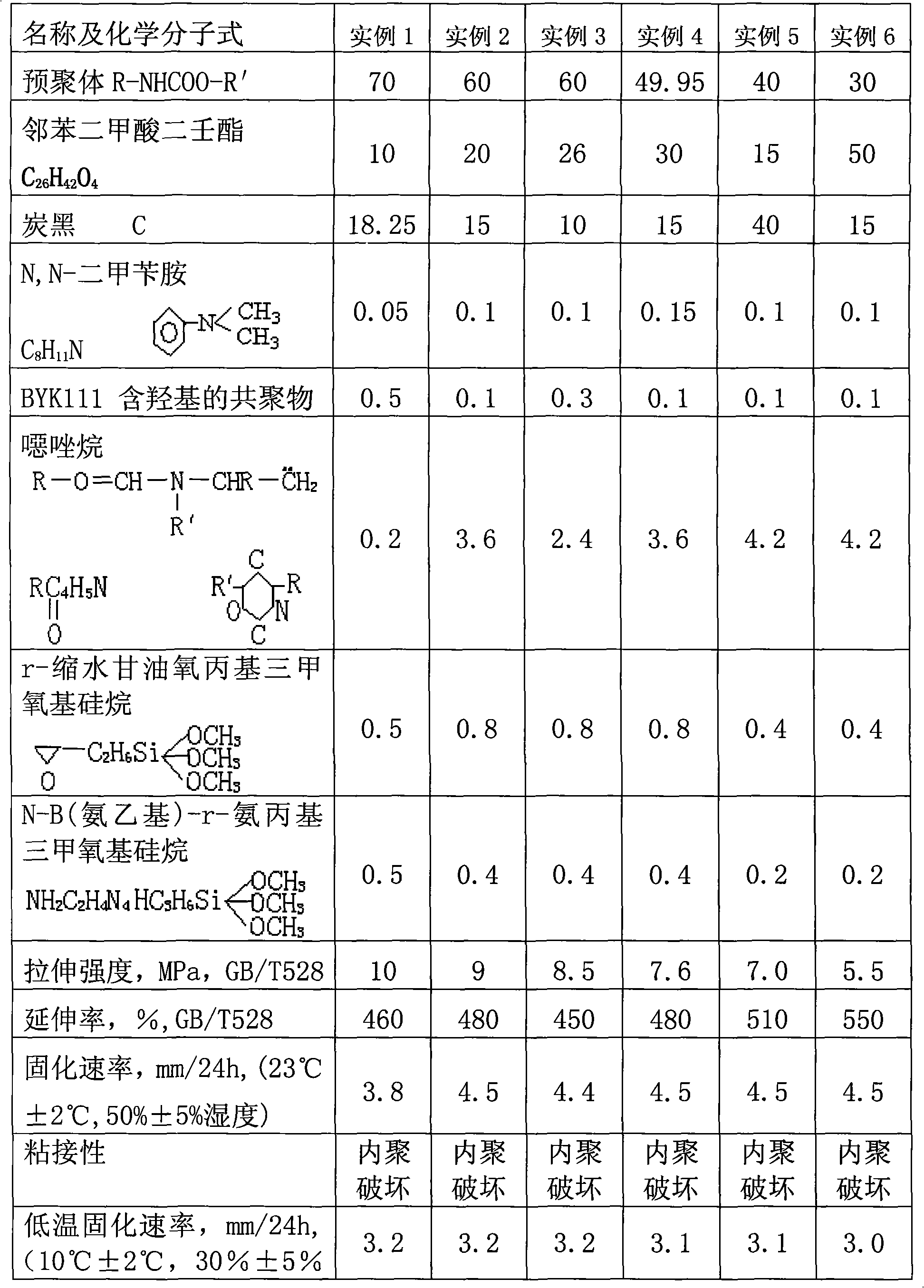

[0029] In order to further illustrate the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation of the polyurethane sealant proposed according to the present invention will be described in detail below in conjunction with the preferred embodiments.

[0030] Synthesis of prepolymers

[0031] The prepolymer is 30-60% by weight of polyoxypropylene diol (molecular weight 1500-4000), 20-55% of polyoxypropylene trihydric alcohol (molecular weight 4800-6500), 0.5-5 % of hexanediol, 10-30% of 4,4'-diphenylmethane diisocyanate and 0.1-0.5% of dibutyltin dilaurate (as a catalyst), under the protection of nitrogen in the reactor, at 90 ℃ -100 It can be obtained by reacting at ℃ for 2-5 hours. The prepolymer is a difunctional terminal isocyanate with a molecular weight of at least 1500 or more, a trifunctional terminal isocyanate with a molecular weight of at least 4800 or a mixture thereof, or an intermediate p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com