Colloid storage battery filling process and device

A technology of colloidal battery and colloidal electrolyte, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of battery consistency deviation, battery thermal runaway, and no control time interval, and achieves a longer time and improved accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

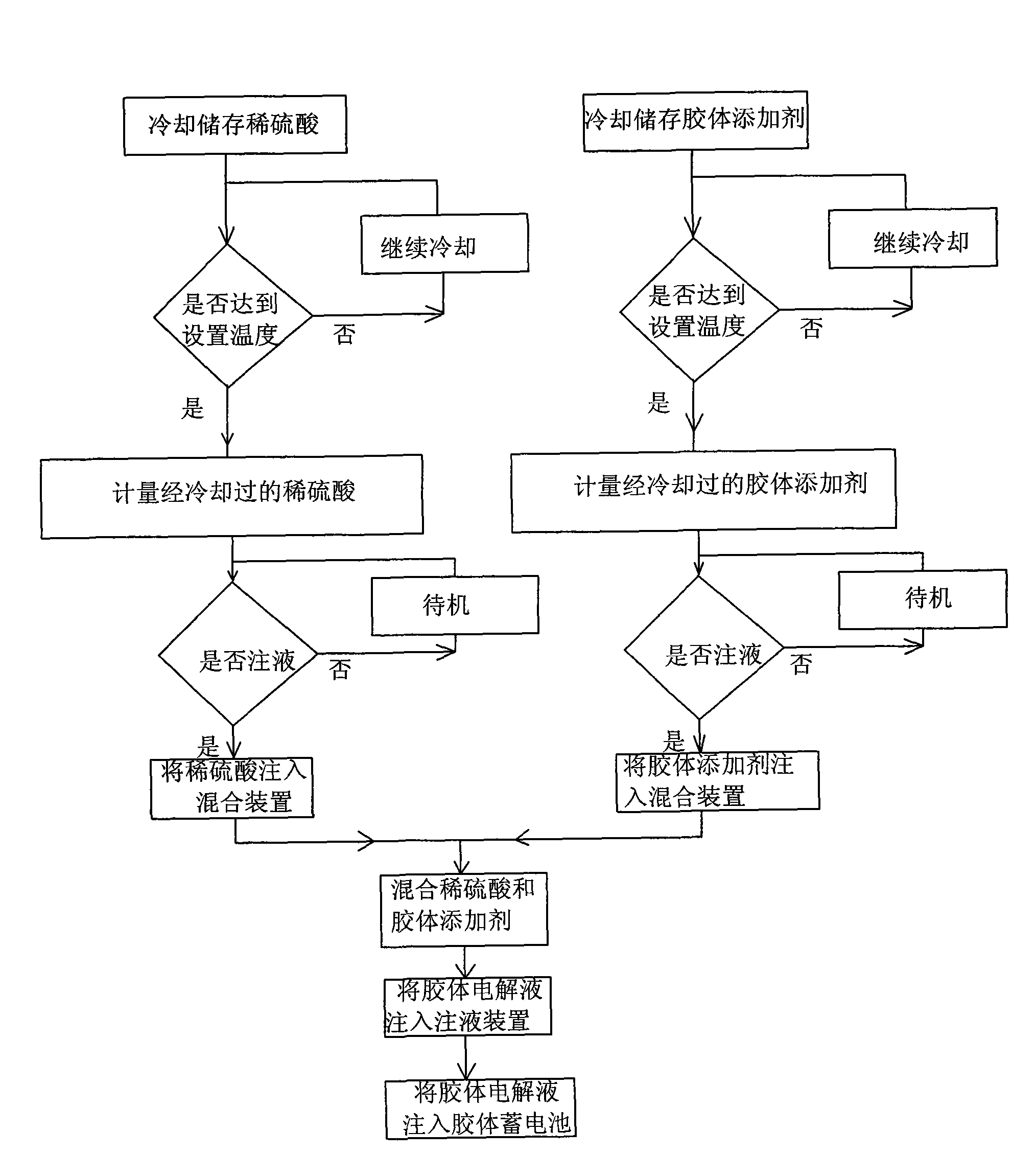

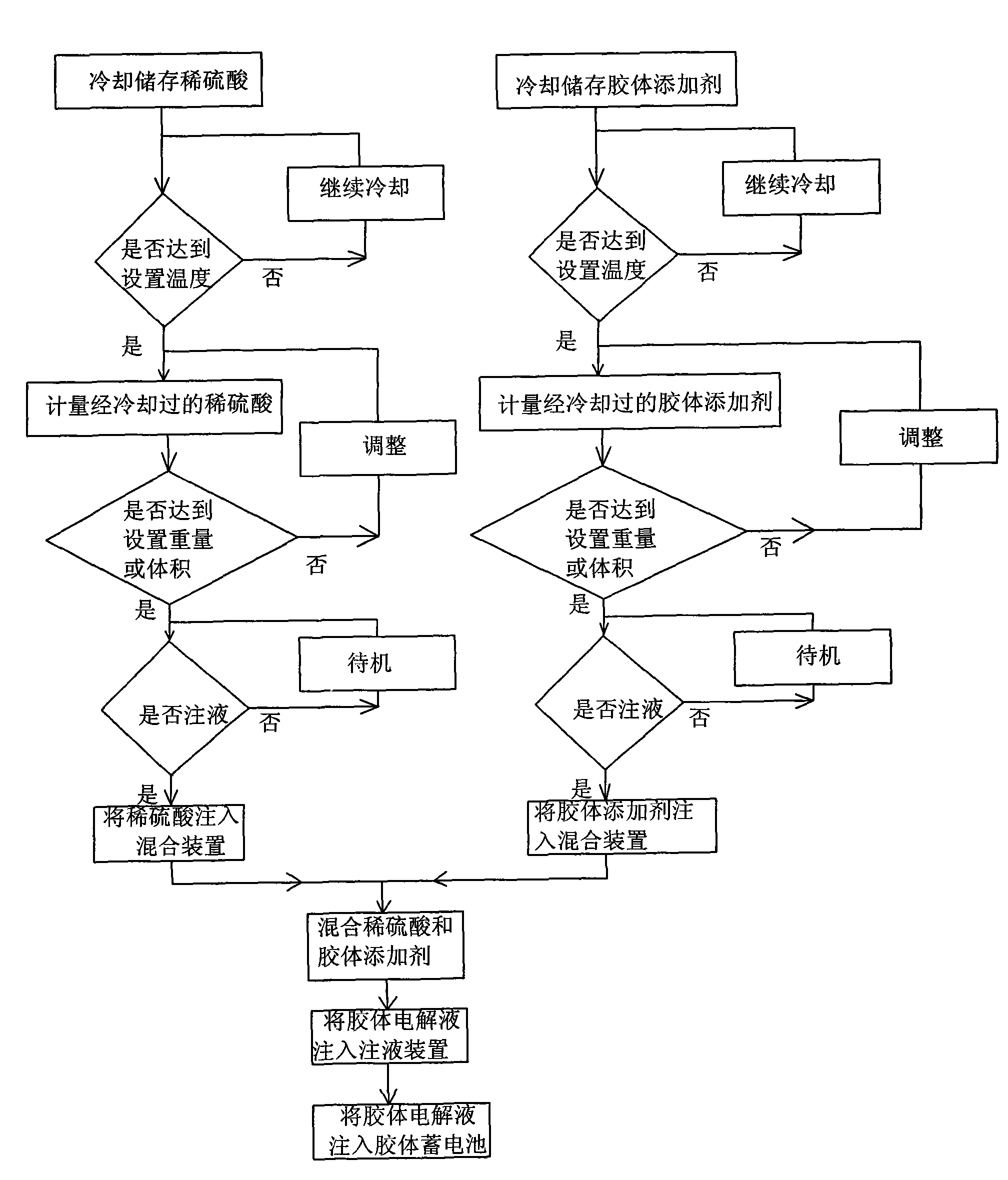

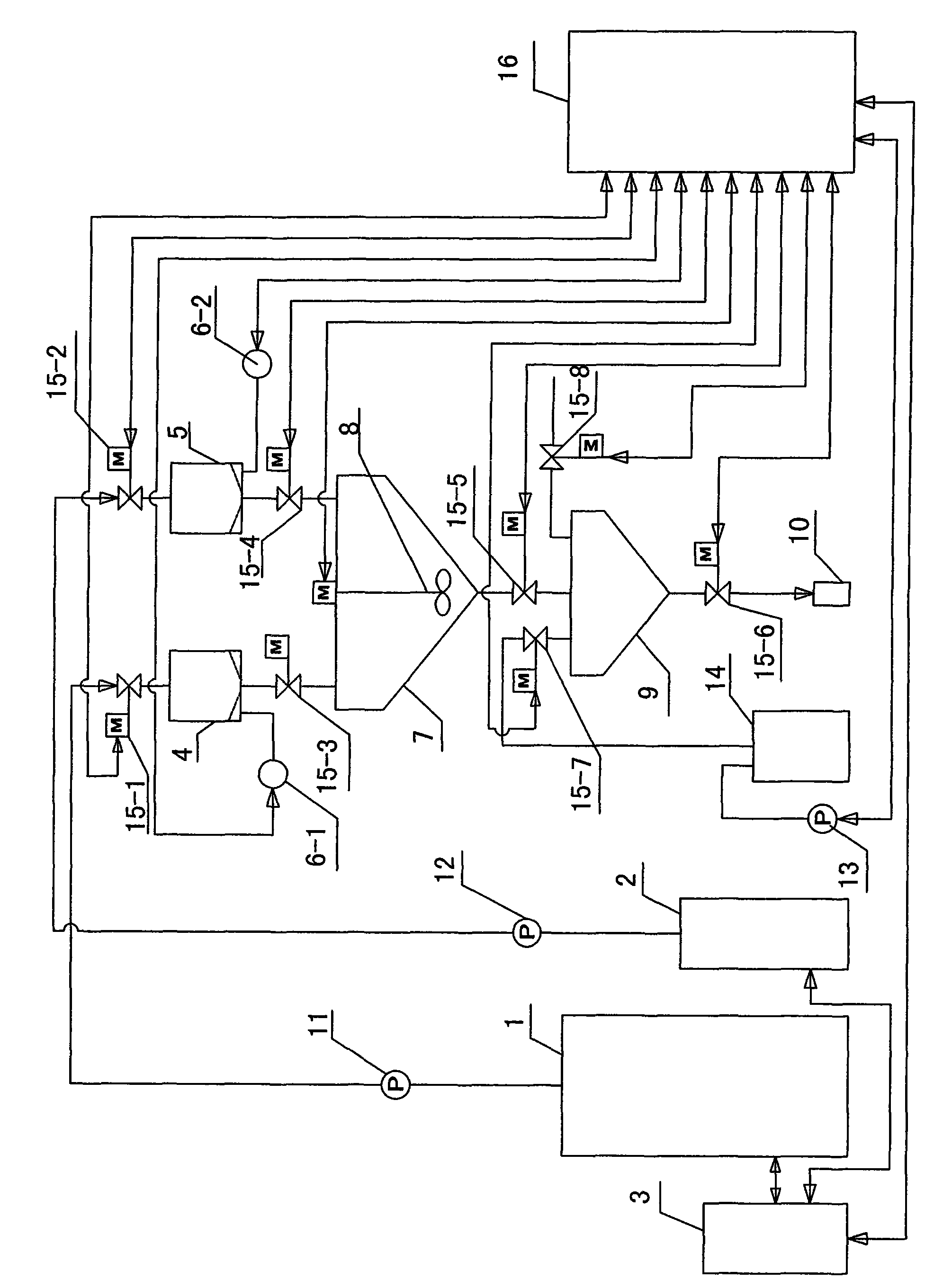

Method used

Image

Examples

Embodiment 1

[0048] First, according to the usual process, mix dilute sulfuric acid with a specific gravity of 1.270 g / ml at room temperature and colloidal additives in a 400-liter container at a weight ratio of 9:1 to form a 350-liter colloidal electrolyte, and then use ordinary The liquid injection equipment weighs the mixed colloidal electrolyte, and then injects it into the battery by vacuuming. In this embodiment, a total of 48 liquid-injected valve-controlled sealed lead-acid batteries are used, and the battery model is GFMJ500. The injection volume is 7.0 liters per mouse. It took 24 minutes to complete the injection of 48 batteries, that is to say, it took at least 24 minutes from the beginning of mixing dilute sulfuric acid and colloid additive to the completion of the last injection of 48 batteries. The gel electrolyte of each battery is different from the beginning of mixing to filling time. The shortest is 0.5 points and the longest is 24 points. After liquid injection, afte...

Embodiment 2

[0066]First, according to the usual process, mix dilute sulfuric acid with a specific gravity of 1.270 g / ml at room temperature and colloidal additives in a 400-liter container at a weight ratio of 9:1 to form a 350-liter colloidal electrolyte, and then use ordinary The liquid injection equipment weighs the mixed colloidal electrolyte, and then injects it into the battery by vacuuming. In this embodiment, a total of 48 liquid-injected valve-controlled sealed lead-acid batteries are used, and the battery model is GFMJ500. The injection volume is 7.0 liters per mouse. It took 24 minutes to complete the injection of 48 batteries, that is to say, it took at least 24 minutes from the beginning of mixing dilute sulfuric acid and colloid additive to the completion of the last injection of 48 batteries. The gel electrolyte of each battery is different from the beginning of mixing to filling time. The shortest is 0.5 points and the longest is 24 points. After liquid injection, after...

Embodiment 3

[0084] First, according to the usual process, mix dilute sulfuric acid with a specific gravity of 1.270 g / ml at room temperature and colloidal additives in a 400-liter container at a weight ratio of 9:1 to form a 350-liter colloidal electrolyte, and then use ordinary The liquid injection equipment weighs the mixed colloidal electrolyte, and then injects it into the battery by vacuuming. In this embodiment, a total of 48 liquid-injected valve-controlled sealed lead-acid batteries are used, and the battery model is GFMJ500. The injection volume is 7.0 liters per mouse. It took 24 minutes to complete the injection of 48 batteries, that is to say, it took at least 24 minutes from the beginning of mixing dilute sulfuric acid and colloid additive to the completion of the last injection of 48 batteries. The gel electrolyte of each battery is different from the beginning of mixing to filling time. The shortest is 0.5 points and the longest is 24 points. After liquid injection, afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com