Device for precessing acid solution used in corron seed manufacture

A solution treatment and acid processing technology, which is applied in the fields of seed and rhizome treatment, application, agriculture, etc., can solve the problems of seed crushing damage and affecting the germination rate of seeds, etc., and achieve the effect of low damage and good processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

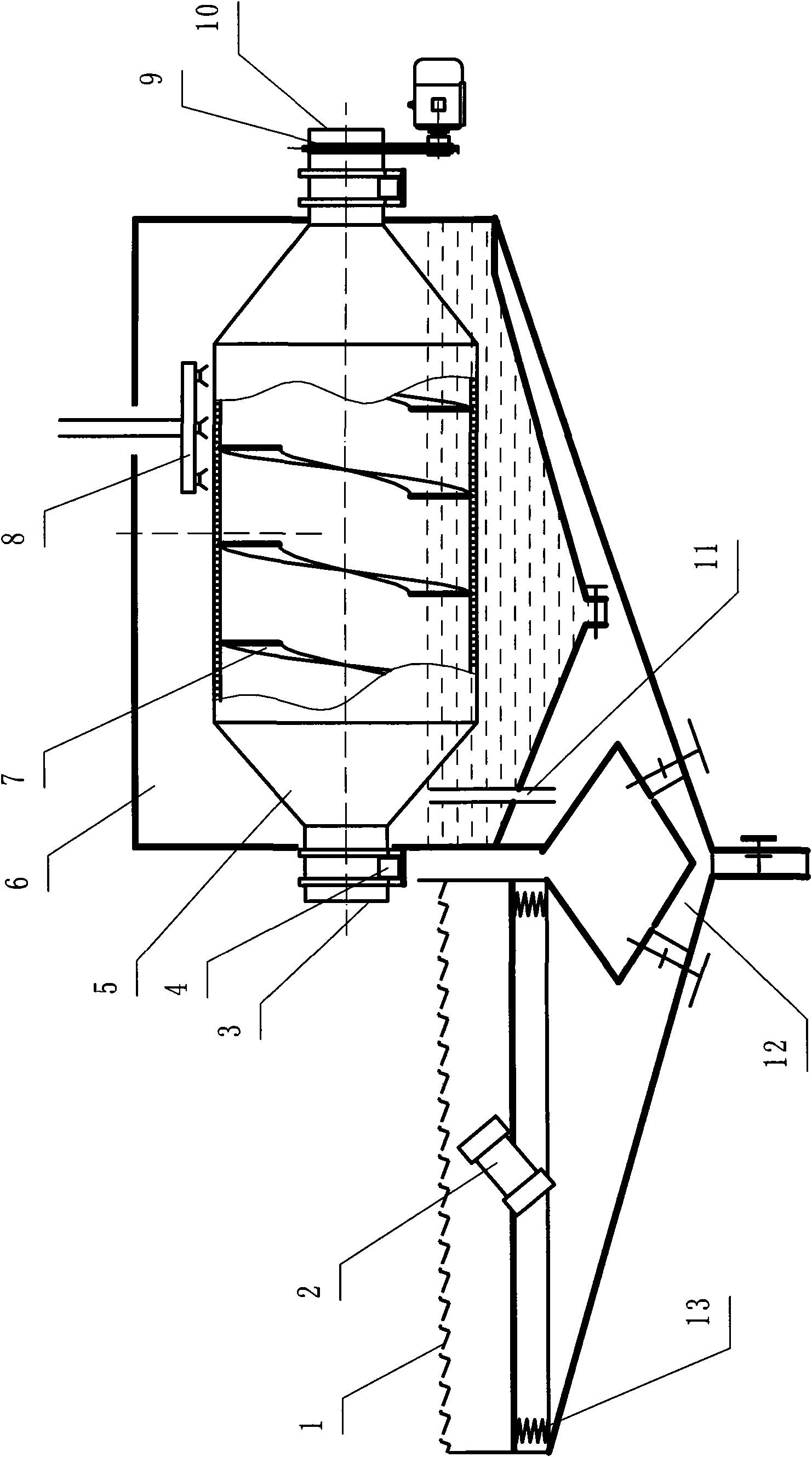

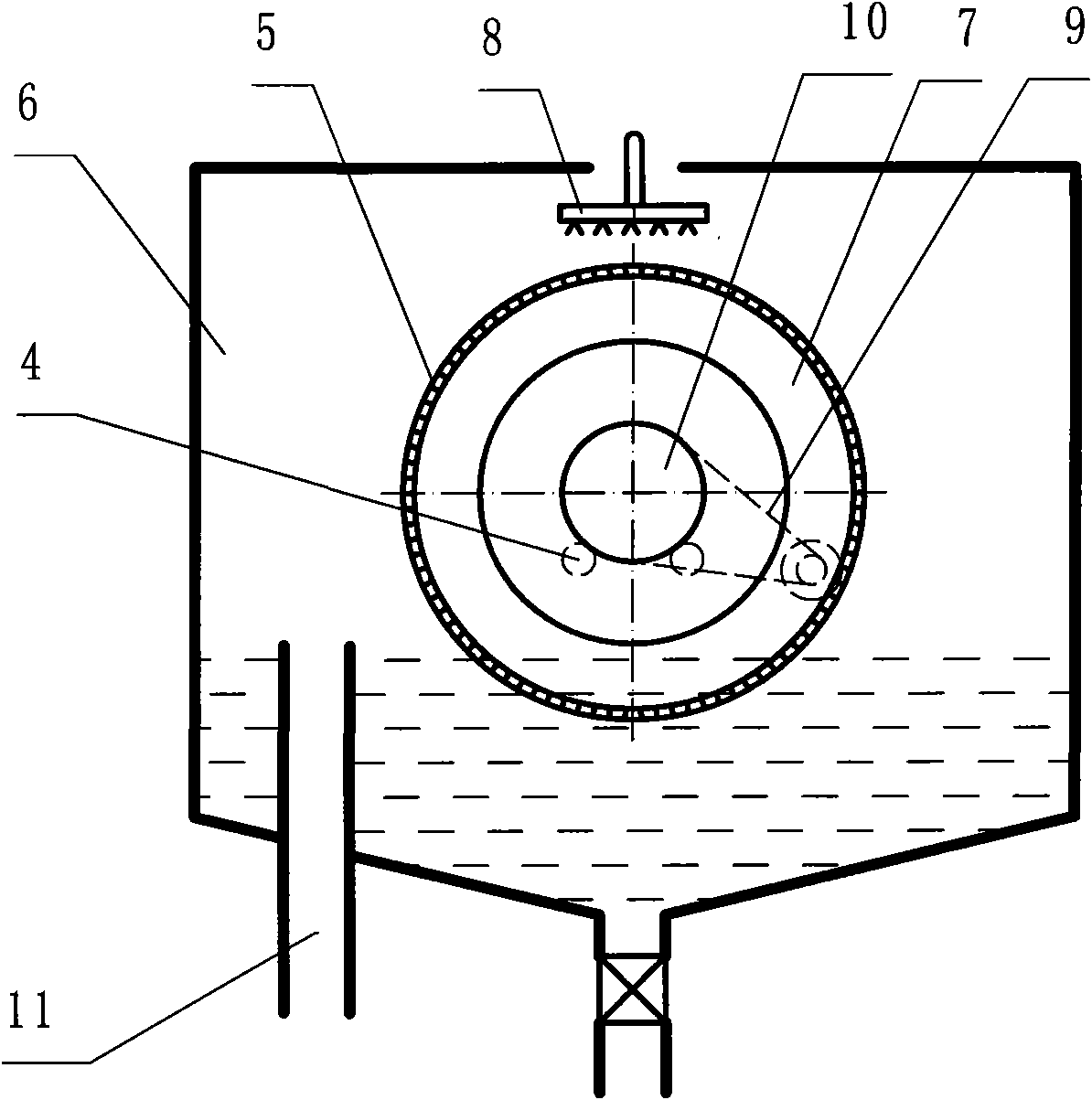

[0016] Refer to attached Figure 1~2 , which is a structural schematic diagram of Embodiment 1 of the present invention, including a frame on which a trommel 5 comprising a feed inlet 10 and a discharge port 3 is arranged, and the trommel 5 is a sieve whose two ends are directly smaller than the middle diameter Stainless steel cylindrical cylinder, the cylinder wall is drilled with dense small holes to form a sieve shape. The trommel 5 is driven by the trommel roller 4 and the trommel driving mechanism 9. The trommel driving mechanism 9 is a sprocket driving mechanism, which is driven by a motor and a chain. Composition, the above-mentioned trommel roller 4 and trommel driving mechanism 9 are arranged at the small end of the trommel 5, the inner wall of the trommel 5 is provided with a spiral propulsion blade 7, and the lower part of the trommel 5 is provided with an acid pool 6, The acid solution is injected into the acid solution pool 6 through the acid solution injection pi...

Embodiment 2

[0018] Compared with Embodiment 1, the difference of this embodiment is that the overflow pipe 11 is telescopic and adjustable.

Embodiment 3

[0020] Compared with Embodiment 1, the difference of this embodiment is that the sieve plate 1 is a flat screen or an odd-shaped screen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com