Material for repairing defect of human body bone and preparation method thereof

A bone defect and human body technology, applied in the direction of prosthesis, medical science, coating, etc., can solve the problems of degradability and insufficient strength, and achieve the effect of eliminating or reducing stress shielding and good permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Preparation of materials for repairing human bone defects with a diameter of 1mm, the specific steps are as follows:

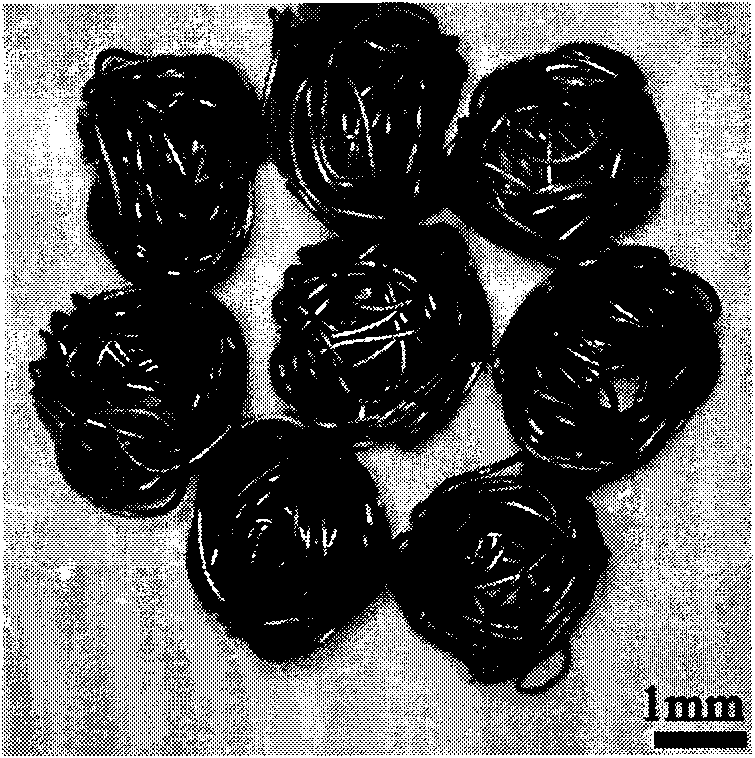

[0026] The first step is to randomly wind and shape pure titanium fibers with a diameter of 50 μm to prepare fibrous porous titanium microspheres with irregular three-dimensional interconnected pores. The diameter of the microspheres is 1 mm, the porosity is 78.0%, and the pore size distribution is 100-500 μm , the pores are interconnected, such as figure 1 As shown, the fibrous porous titanium microspheres were ultrasonically cleaned with distilled water for 10 minutes, and then sterilized under high temperature and high pressure for later use;

[0027] The compressive strength of the fibrous porous titanium microspheres is 16.0MPa, and the modulus of elasticity is 1.20GPa;

[0028] In the second step, 5 g of nano-strontium apatite with a purity of 99.99% was ultrasonically cleaned with distilled water for 10 minutes, sterilized by high temp...

Embodiment 2

[0030] Embodiment 2 prepares the material of the human body bone defect repair of diameter 2mm, concrete steps are as follows:

[0031] The first step is to randomly wind and shape pure titanium fibers with a diameter of 80 μm to prepare fibrous porous titanium microspheres with irregular three-dimensional interconnected pores. The diameter of the microspheres is 2 mm, the porosity is 80.0%, and the pore size distribution is 100-600 μm , the pores are interconnected, such as figure 1 As shown, it was ultrasonically cleaned with distilled water for 10 minutes, and then sterilized under high temperature and high pressure for later use;

[0032] The compressive strength of the described fibrous porous titanium microspheres is 15.6MPa, and the modulus of elasticity is 1.05GPa;

[0033] In the second step, 5 g of nano-strontium apatite with a purity of 99.99% was ultrasonically cleaned with distilled water for 10 minutes, and then sterilized by high temperature and high pressure, ...

Embodiment 3

[0035] Example 3 Preparation of materials for repairing human bone defects with a diameter of 1.5mm, the specific steps are as follows:

[0036] The first step is to randomly wind and shape pure titanium fibers with a diameter of 100 μm to prepare fibrous porous titanium microspheres with irregular three-dimensional interconnected pores. The microspheres have a diameter of 1.5 mm, a porosity of 82.0%, and a pore size distribution of 100- 800μm, the pores are interconnected, such as figure 1 As shown, it was ultrasonically cleaned with distilled water for 10 minutes, and then sterilized by high temperature and high pressure for later use.

[0037] The compressive strength of the fibrous porous titanium microspheres is 15.0MPa, and the modulus of elasticity is 0.90GPa;

[0038] In the second step, 5 g of nano-strontium apatite with a purity of 99.99% was ultrasonically cleaned with distilled water for 10 minutes, and then sterilized by high temperature and high pressure, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Pore size distribution | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com