Preparing method of ortho-nitrobenzonitrile series compound

A technology for o-nitrobenzonitrile and compound, which is applied in the field of preparation of o-nitrobenzonitrile compounds, can solve the problems of being difficult to obtain, expensive 3-nitro-4-bromotrifluorotoluene and the like, and achieves reaction selectivity And the effect of high conversion rate, shortened reaction time and simplified process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

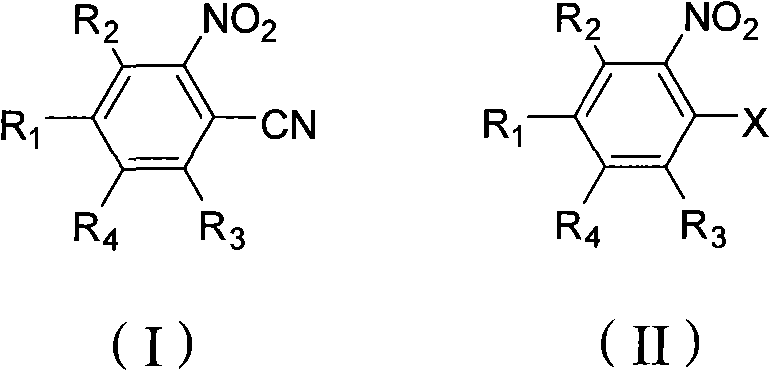

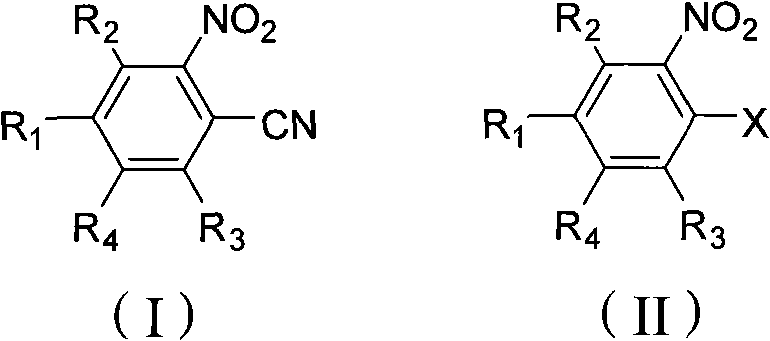

Method used

Image

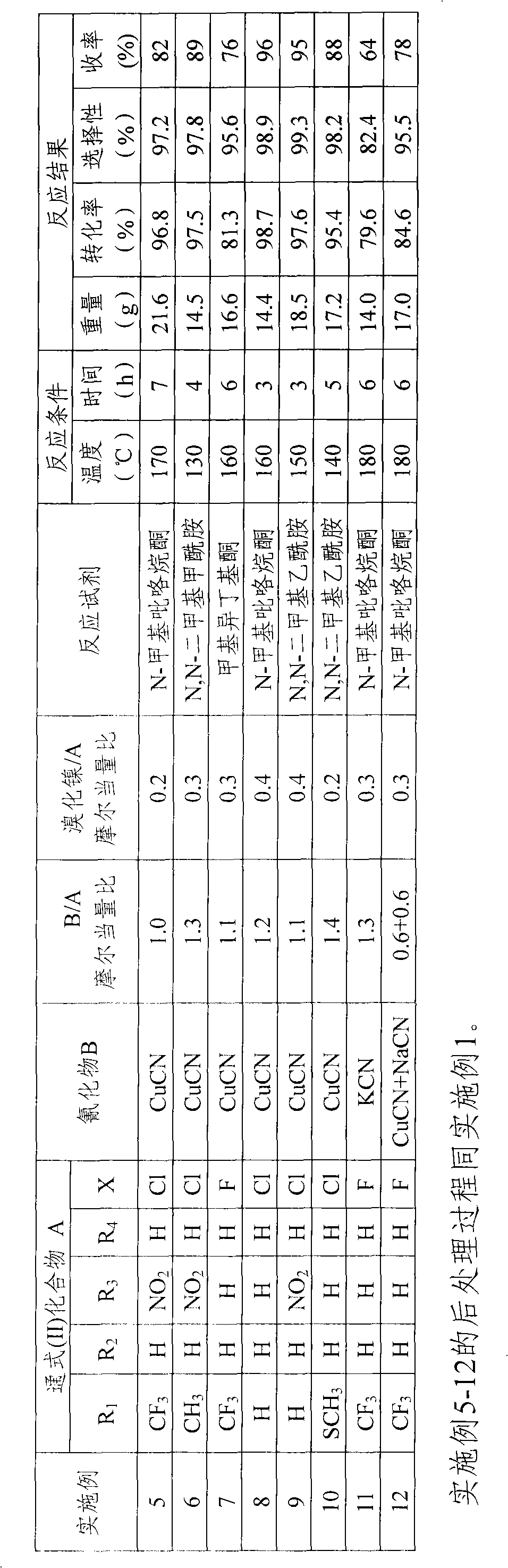

Examples

Embodiment 1

[0024] Example 1 Preparation of 2-nitro-4-trifluoromethylbenzonitrile

[0025] Under the protection of passing through dry nitrogen, 130g of N-methylpyrrolidone, 22.6g (0.1mol) of 3-nitro-4-chlorobenzotrifluoride, 8.9g (40mmol) of nickel bromide, and cyanide were successively added to the reaction flask. Cuprous 9.0g (0.1mol). Turn on stirring, heat to 160° C., and stir for 3 hours. Subsequently, the temperature was lowered to room temperature under the protection of nitrogen, and samples were taken for GC-MS analysis. The analysis results were: the reaction conversion rate was 99.8%, and the reaction selectivity was 98.8%. Add 600mL of ether and 150mL of water, stir, separate the organic phase, extract the water phase twice with 30mL of ether, combine the organic phases, dry over sodium sulfate water and decolorize with activated carbon to obtain 19.5g of yellow solid with a yield of 90%. The mass spectral data (EI) of 2-nitro-4-trifluoromethylbenzonitrile is: 216 (M + )19...

Embodiment 2

[0026] Example 2 Preparation of 2-nitro-4-trifluoromethylbenzonitrile

[0027] Under the protection of passing through dry nitrogen, 130g of sulfolane, 22.6g (0.1mol) of 3-nitro-4-chlorobenzotrifluoride, 4.5g (20mmol) of nickel bromide, and 10.8g of cuprous cyanide were successively added to the reaction flask (0.12 mol). Turn on stirring, heat to 170°C, and stir for 5 hours. Subsequently, the temperature was lowered to room temperature under the protection of nitrogen, and samples were taken for GC-MS analysis. The analysis results were: the reaction conversion rate was 96.5%, and the reaction selectivity was 99.0%. Add 600mL of ether and 150mL of water, stir, separate the organic phase, extract the water phase twice with 30mL of ether, combine the organic phases, dry over anhydrous sodium sulfate and decolorize with activated carbon to obtain 18.8g of a yellow solid with a yield of 87%.

Embodiment 3

[0028] Example 3 Preparation of 2-nitro-4-trifluoromethylbenzonitrile

[0029] Under the protection of feeding dry nitrogen, benzonitrile 30g, 3-nitro-4-chlorobenzotrifluoride 4.5g (20mmol), nickel bromide 0.45g (2mmol), PEG-400 (poly Ethylene glycol) 30g, cuprous cyanide 2.2g (0.024mol). Start stirring, heat to 180°C, and stir for 6 hours. Subsequently, the temperature was lowered to room temperature under the protection of nitrogen, and samples were taken for GC-MS analysis. The analysis results were as follows: the reaction conversion rate was 90.5%, and the reaction selectivity was 79.0%. Add 120mL of ether and 30mL of water, stir, separate the organic phase, extract the aqueous phase twice with 10mL of ether, combine the organic phases, dry over anhydrous sodium sulfate and decolorize with activated carbon, and desolventize to obtain 2.9g of a yellow solid with a yield of 66%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com