Heat supply system for electric heating organic heat carrier

A heating system and electric heating technology, applied in heating systems, household heating, heating methods, etc., can solve problems such as limited heat energy, scale generation, high air pressure, etc., and achieve slow thermal decomposition speed, low maintenance cost, and heat good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

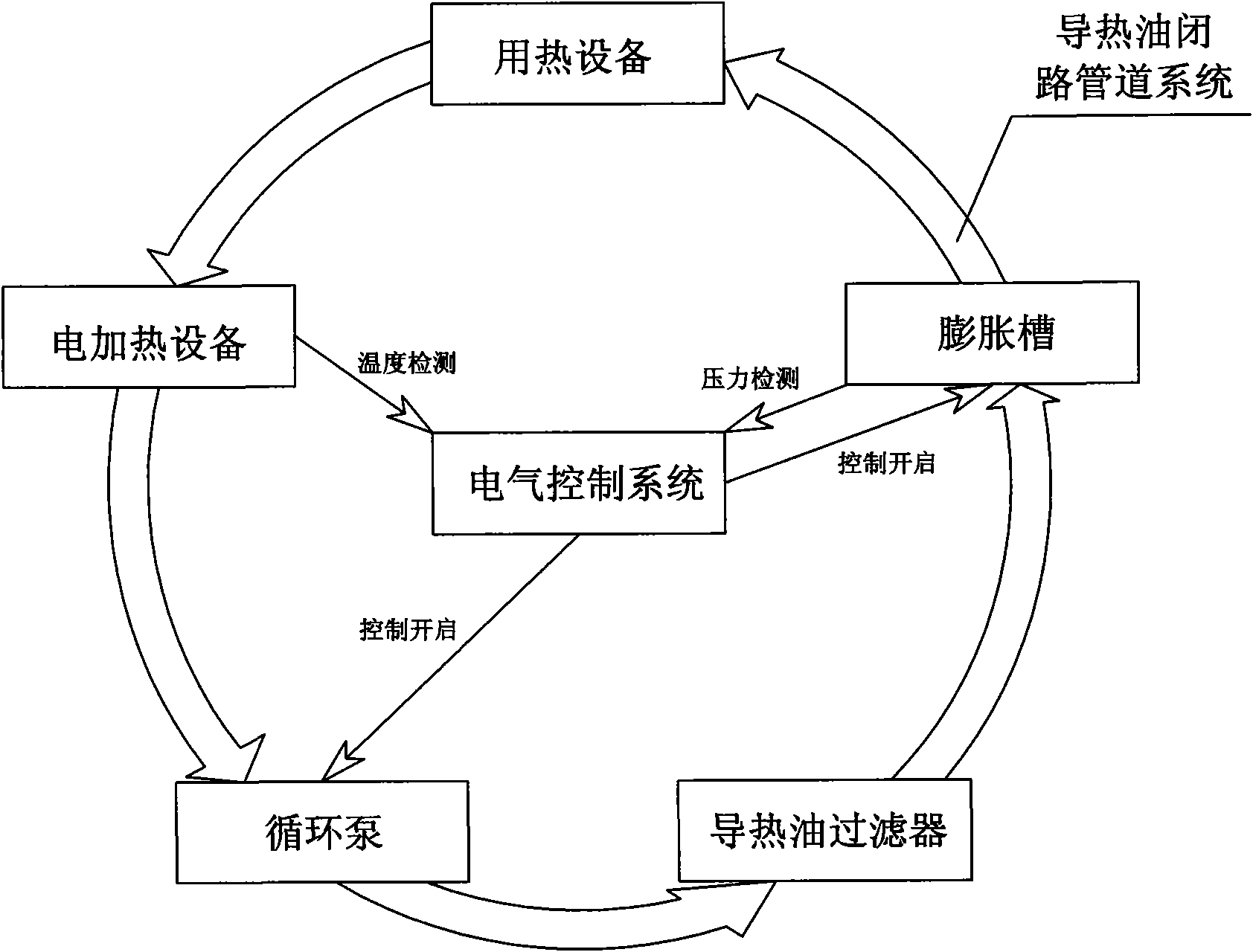

[0010] The working process of the present invention is as follows: the heat-conducting oil at normal temperature is heated by electric heating equipment, and the temperature is raised to above 200°C and below 500°C. After the heat-conducting oil is fully heated to reach the boiling point of the heat-conducting oil, a The temperature sensing device sends a signal to the electrical control system; then the electrical control system turns on the circulation pump, the circulation pump starts to work, and continuously generates power to push the heat transfer oil to the heat transfer oil filter; filter out mechanical impurities and carbon particles in the heat transfer oil After mixing with the polymer, the heat transfer oil in the high temperature state enters the expansion tank. After the pressure detector in the expansion tank detects the pressure in the heat transfer oil pipeline, the pressure compensation is performed for the volume change of the heat transfer oil after heating....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com