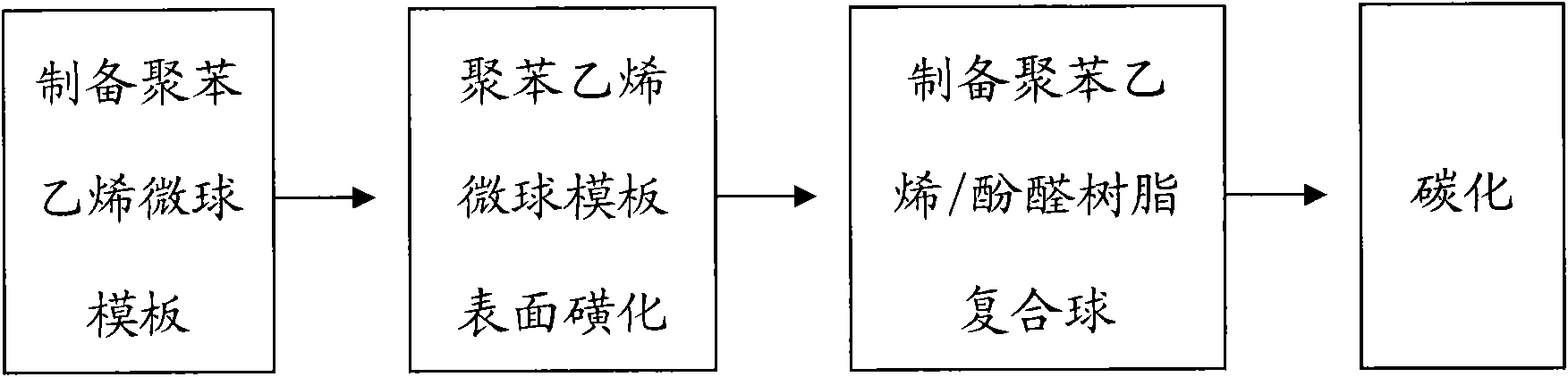

Method for preparing hollow carbon balls

A carbon sphere and hollow technology is applied in the field of preparation of hollow carbon spheres, which can solve the problem of high cost and achieve the effects of low cost, simple and easy method and uniform size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

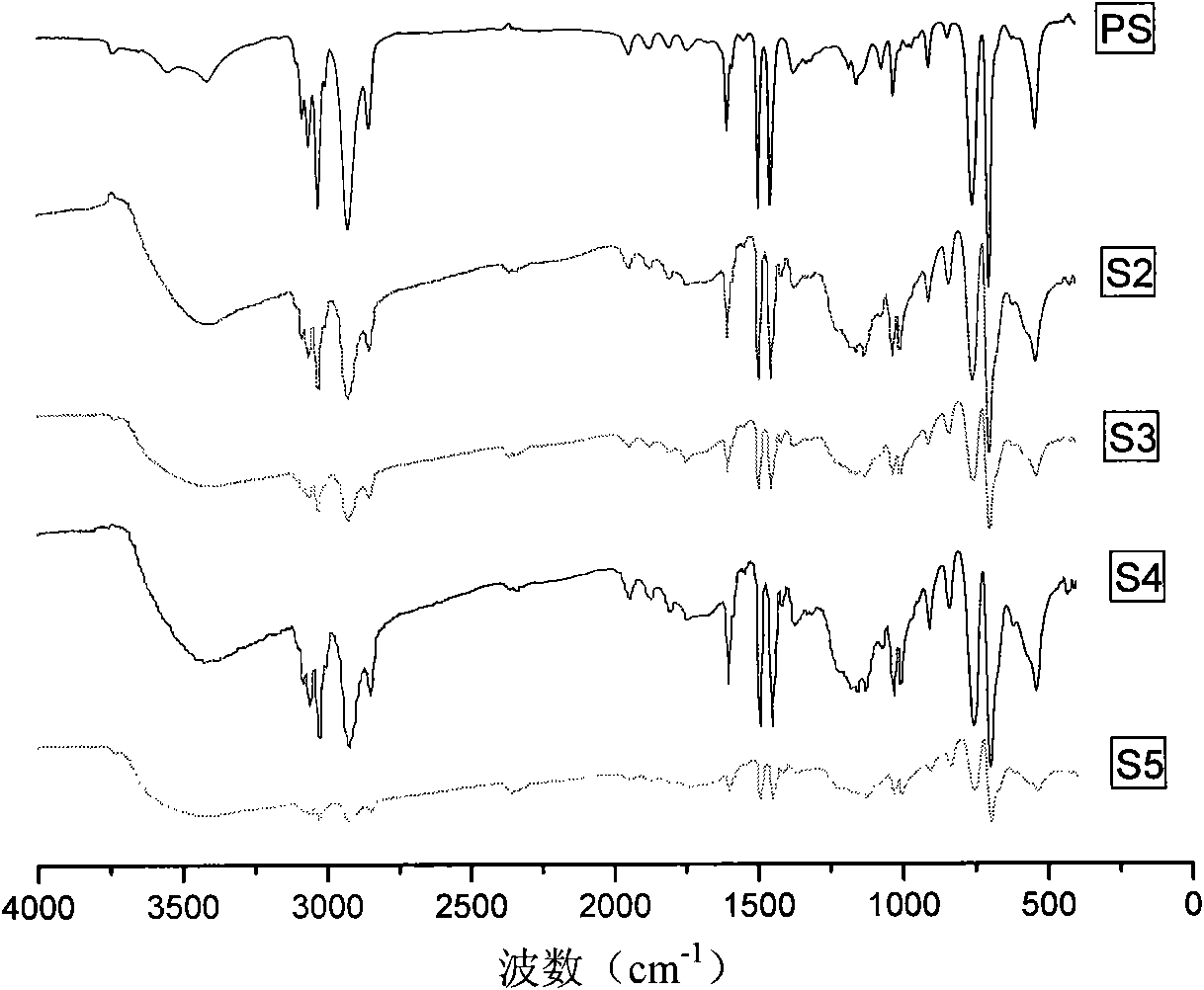

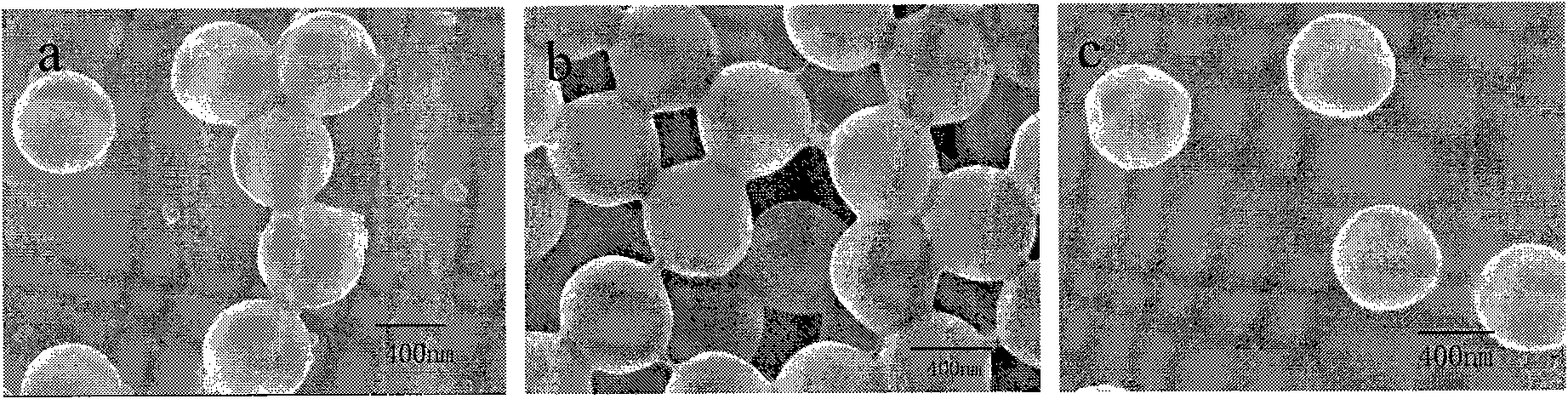

[0022] 1) 0.22g sodium lauryl sulfate and 0.1g potassium persulfate are dissolved in 150ml ethanol aqueous solution (the volume ratio of ethanol and deionized water is 5: 2), add 9ml styrene (decompression distillation removes polymerization inhibitor), Stir evenly at high speed under nitrogen flow, polymerize at 70°C for 8 hours, after the polymerization is completed, cool the reaction system to room temperature, and centrifuge to obtain white powder, namely polystyrene microspheres, and dry at 60°C;

[0023] 2) Add 3 g of dried polystyrene microspheres to 30 ml of concentrated sulfuric acid with a mass fraction of 98%, disperse by ultrasonic vibration, and react at 40° C. for 2 hours, and use the obtained sulfonated polystyrene microsphere template with Washed with absolute ethanol, dried;

[0024] 3) Take 0.1 g of the dried sulfonated polystyrene microsphere template, ultrasonically disperse it in 20 ml of absolute ethanol, and under stirring, drop into 20 ml of absolute et...

Embodiment 2

[0027] 1) with embodiment 1 step 1);

[0028] 2) Add 3 g of dried polystyrene microspheres to 30 ml of concentrated sulfuric acid with a mass fraction of 98%, disperse by ultrasonic vibration, and react at 40° C. for 3 hours, wash the obtained product with absolute ethanol, and dry;

[0029] 3) with embodiment 1 step 3);

[0030] 4) Same as step 4) of Example 1.

Embodiment 3

[0032] 1) with embodiment 1 step 1);

[0033] 2) Add 3 g of dried polystyrene microspheres to 30 ml of concentrated sulfuric acid with a mass fraction of 98%, disperse by ultrasonic vibration, and react at 40° C. for 4 hours, wash the obtained product with absolute ethanol, and dry;

[0034] 3) with embodiment 1 step 3);

[0035] 4) Same as step 4) of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com