Device for positioning and supporting base of vacuum equipment

A technology of vacuum equipment and positioning support, used in vacuum evaporation plating, ion implantation plating, gaseous chemical plating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The embodiments of the present invention are described below through specific specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

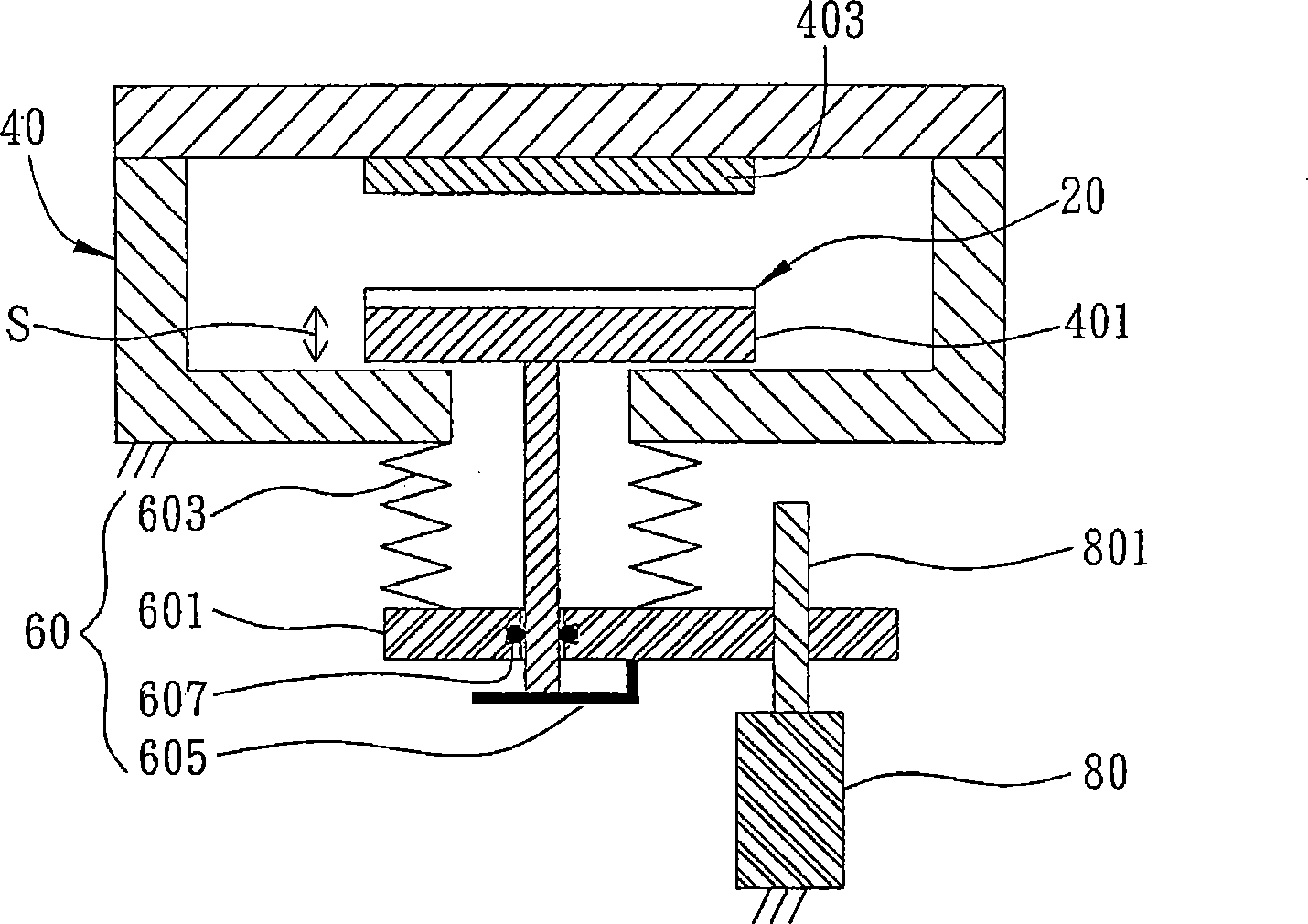

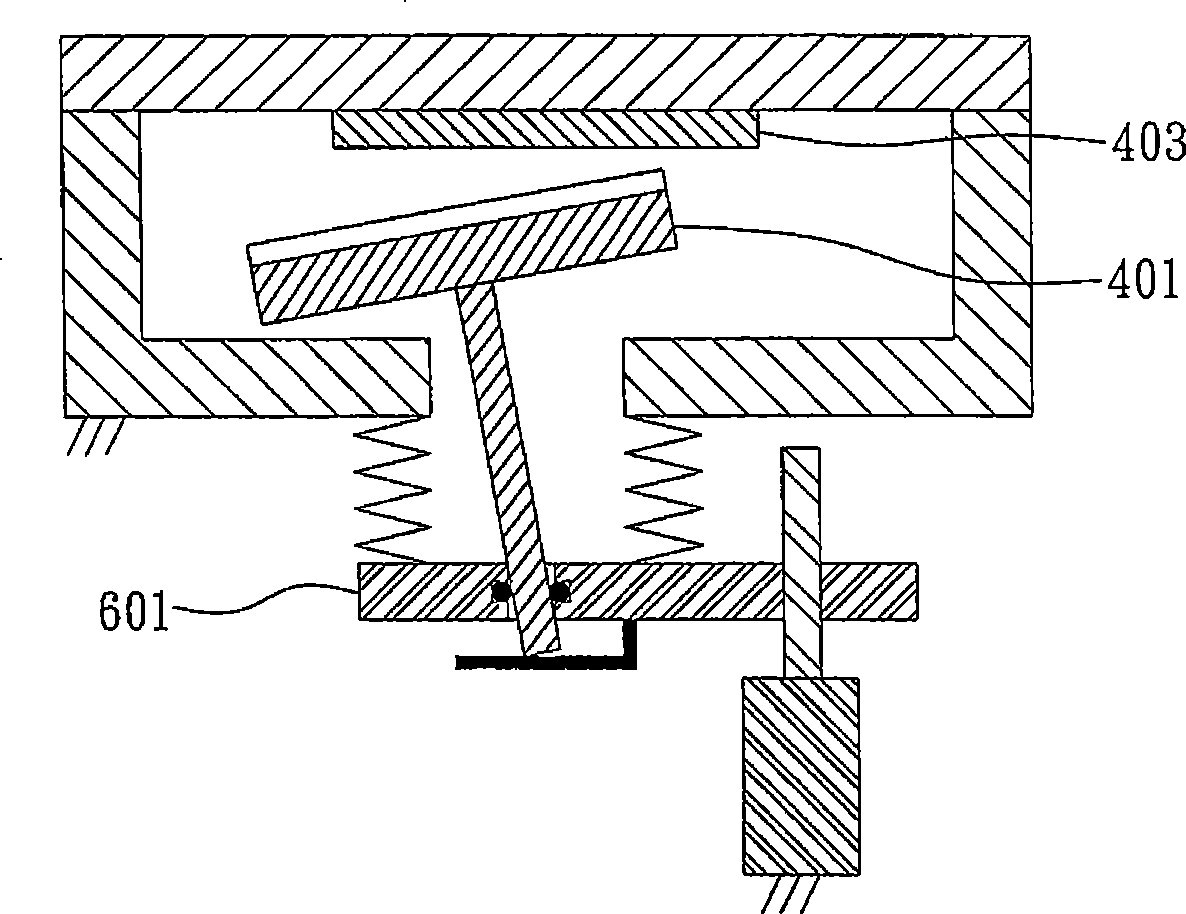

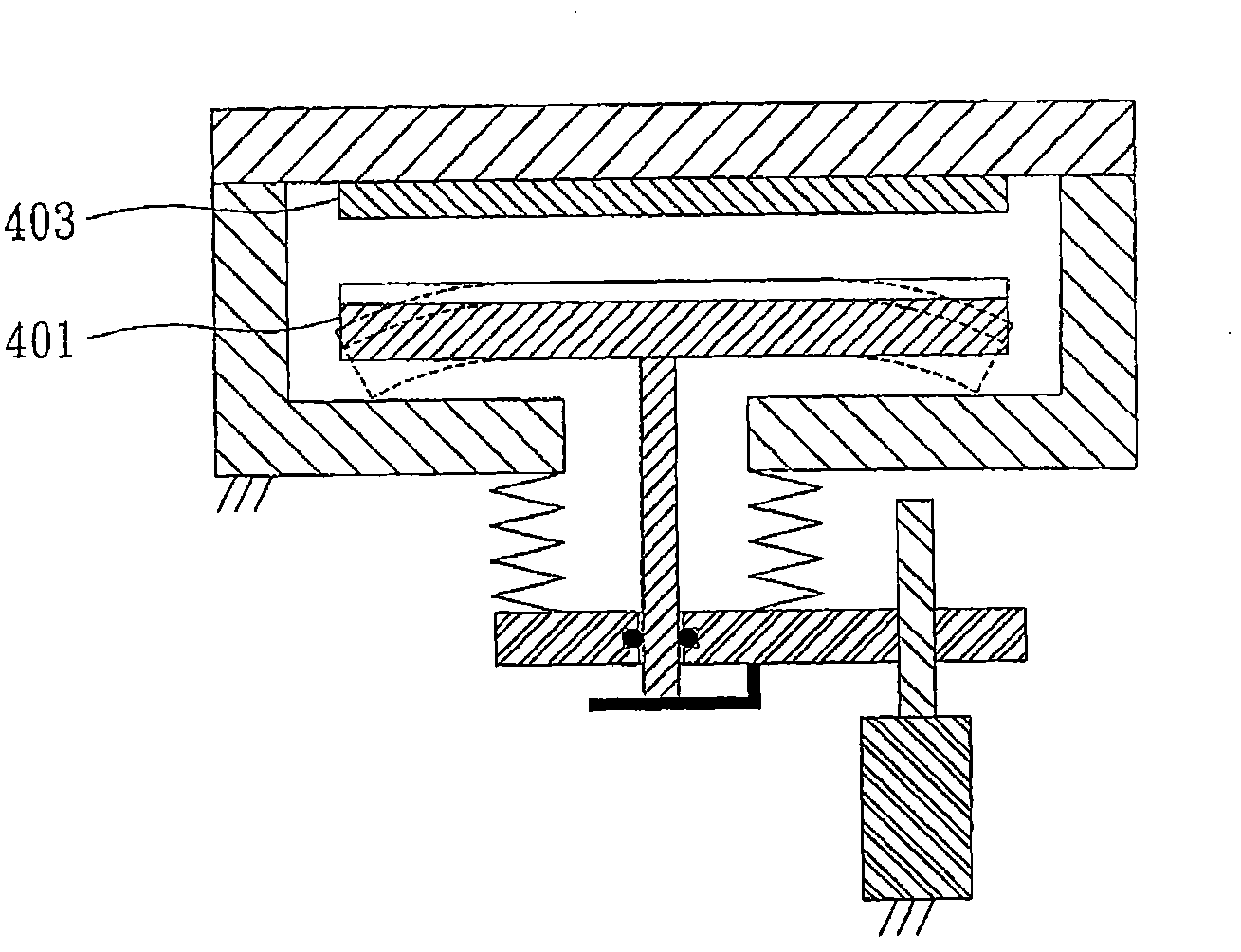

[0073] figure 2 It is a drawing drawn according to the first embodiment of the base positioning and supporting device of the vacuum equipment according to the present invention, as shown in the figure. figure 2 As shown, the base positioning and supporting device of the vacuum equipment in this embodiment is applied to position and support the base 10 to the coating cavity 40 of the vacuum equipment. The susceptor 10 can be lifted and lowered in the coating chamber 40 of the vacuum equipment, and has a substrate receiving portion 101 for carrying a substrate (not shown) and a center shaft portion 103 of the susceptor connecting the substrate receiving portion 101, and the two The center axis is the center axis of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com