Method and system for detecting optical micro/nano newton force on spherical membrane

A detection system and detection method technology, applied in the direction of material analysis, measuring devices, scientific instruments, etc. through optical means, can solve the problems of insufficient measurement accuracy, and achieve the effects of low reliability, short life, and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

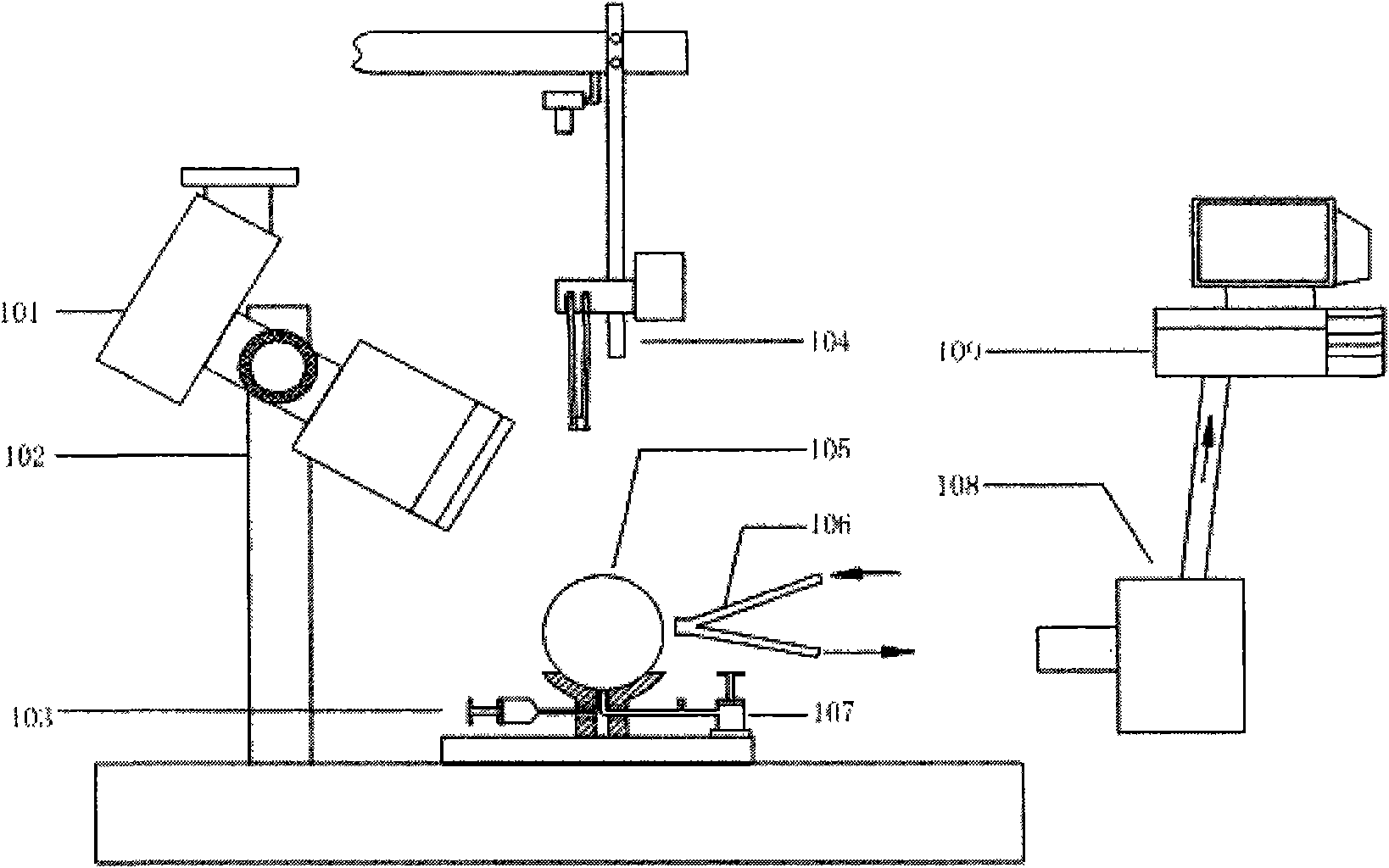

[0019] The spherical membrane optical micro-nano force detection method and system of the present invention will be described below with reference to the accompanying drawings.

[0020] As shown in Figure 1, the spherical membrane optical micro-nano force detection method and system of the present invention include:

[0021] Microscope 101, loaded on the micro-operation platform, used for magnified observation when microparticles are loaded;

[0022] The micro-operation platform 102, the entire detection process is carried out on the micro-operation platform, the micro-operation platform in the figure mainly refers to the physical structure of the micro-operation platform, which is used to load the microscope, as a rigid physical platform for the micro-drive mechanism and the micro-particle clamping mechanism;

[0023] Disposable spherical membrane elimination mechanism 103, after the detection is completed, eliminates the disposable spherical membrane to prevent the disposabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com