Water power extrusion fertilizer applicator

A fertilizer and hydraulic technology, applied in the field of agricultural irrigation, can solve the problems of high mechanical sealing and manufacturing precision, reliability and durability, and large changes in the concentration of fertilizer solutions, etc., to achieve improved corrosion resistance, light weight, The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

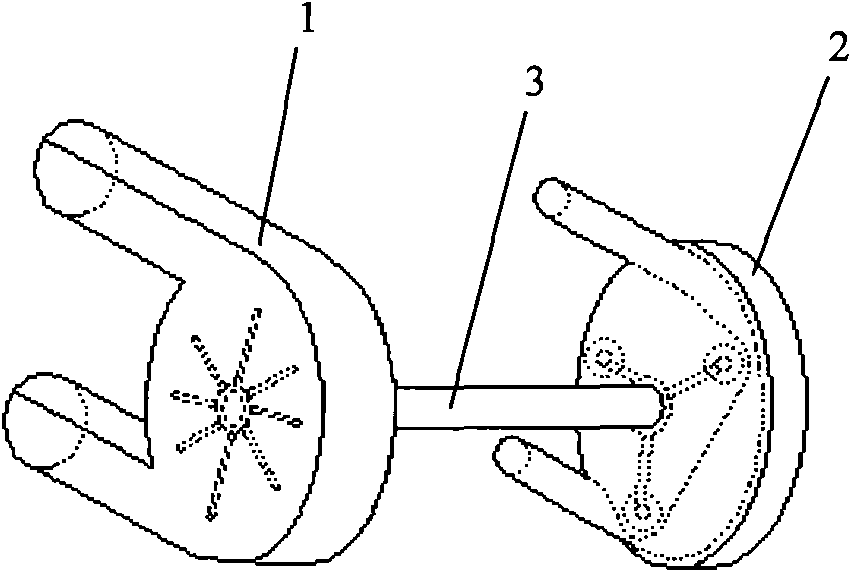

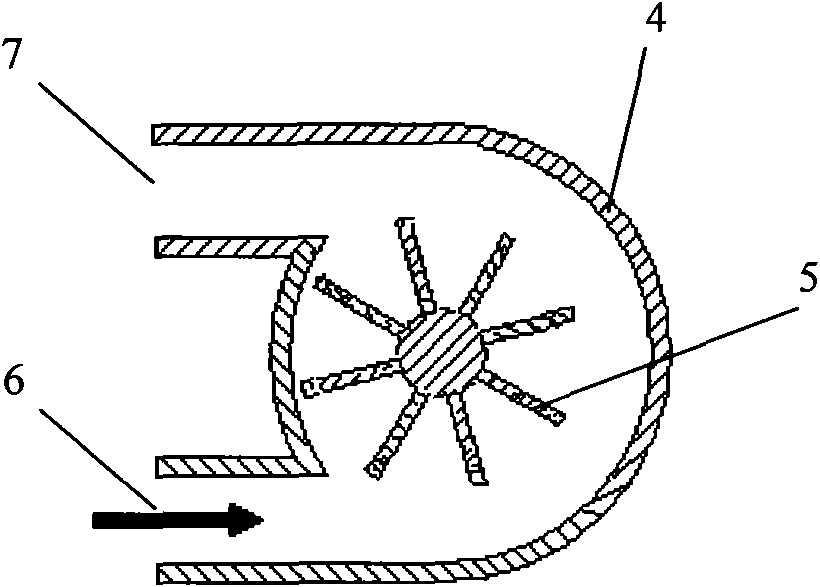

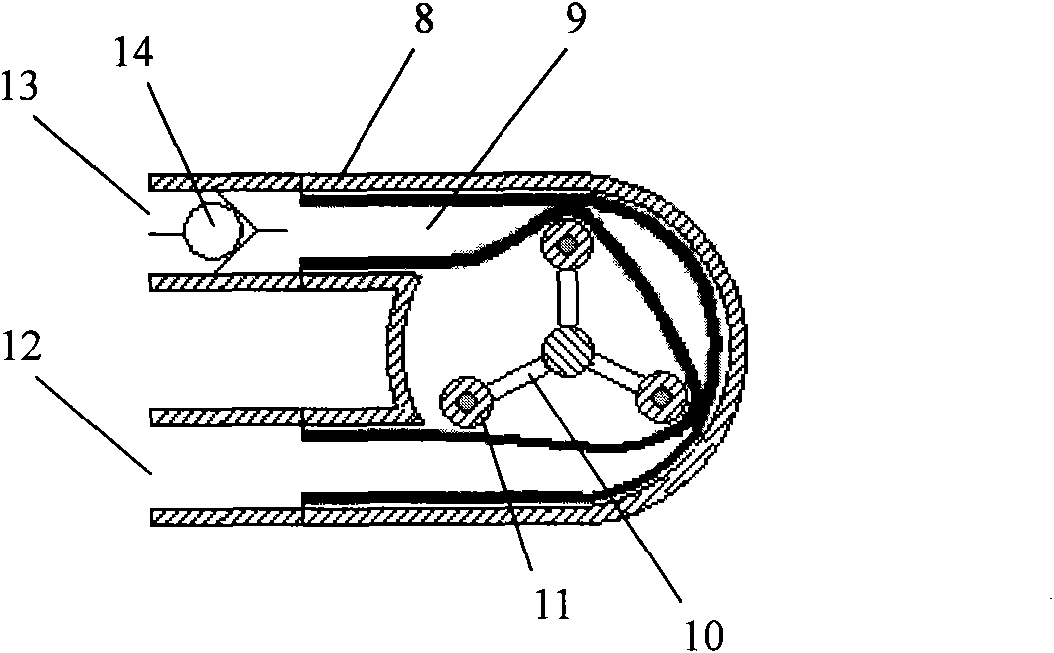

[0015] refer to figure 1 , figure 2 and image 3 . The impeller 5 is installed in the casing 4 of the water wheel drive assembly, and the water inlet 6 and the water outlet 7 are arranged on the casing 4 of the water wheel drive assembly to form the water wheel drive assembly 1 . The elastic hose 9 is arranged along the inner cavity wall of the shell 8 of the extrusion fertilization assembly, the rotor 10 is installed in the circular cavity formed by the shell 8 of the extrusion fertilization assembly and the elastic hose 9, and the extrusion wheel 11 is installed on the rotor 10, the extrusion wheel 11 presses on the elastic hose 9, so that the partial section of the elastic hose 9 becomes flat, forming the extrusion fertilization assembly 2. The front end of the transmission shaft 3 is connected with the impeller 5 in the water wheel driving assembly 1, and the rear end of the transmission shaft 3 is connected with the rotor 10 in the extruding fertilization assembly 2 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com