Method for directly producing liquid hydrocarbon in coal oil-gas reservoir

A technology for oil and gas reservoirs and liquid hydrocarbons, which can be used in the preparation of liquid hydrocarbon mixtures, petroleum industry, cracking, etc., and can solve problems such as low yield of liquid hydrocarbons.

- Summary

- Abstract

- Description

- Claims

- Application Information

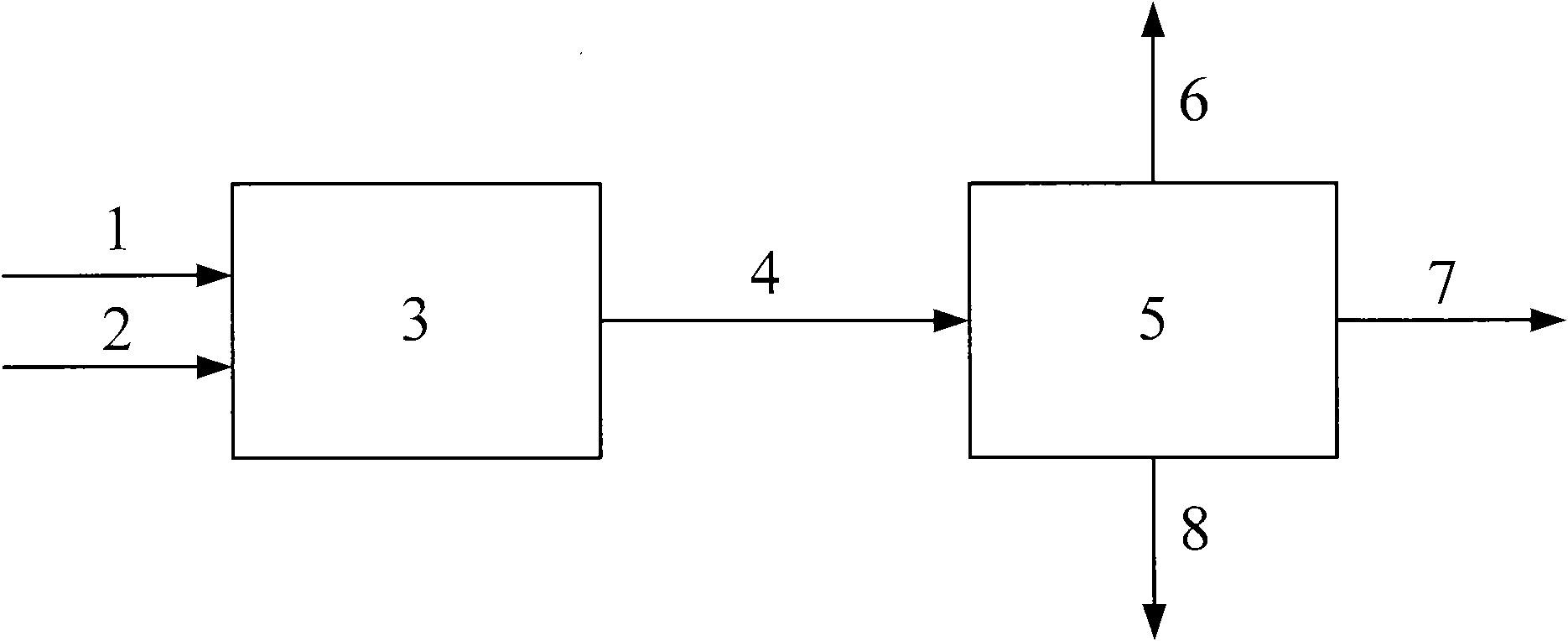

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

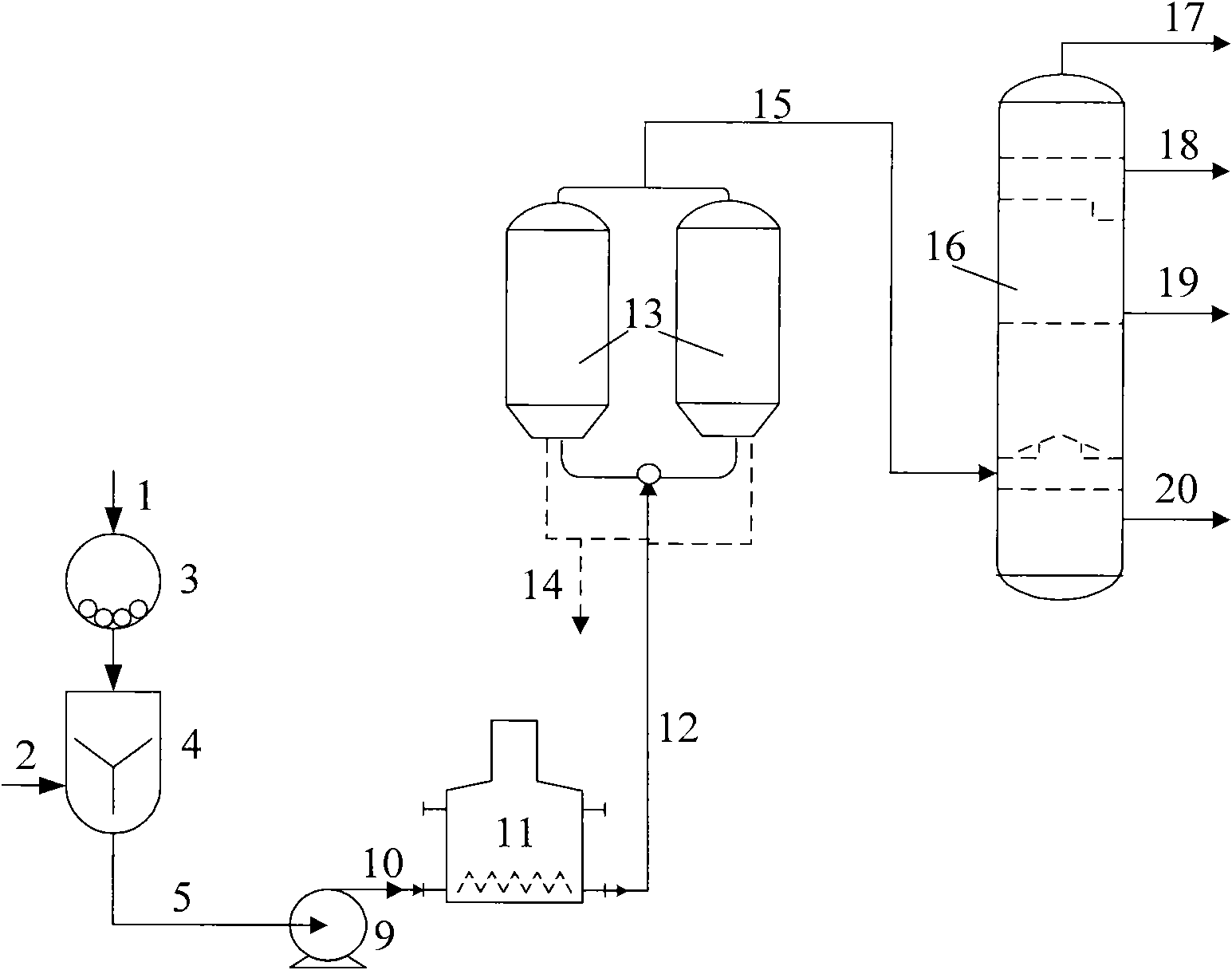

[0042] Pulverize raw coal A to coal powder with a particle size of 100-400 mesh, and 6 # Fuel oil is added to the mixer at a weight ratio of 0.51:1, and the oil-coal slurry is obtained after dissolving at 150°C for 12 hours. After the oil-coal slurry enters the heating furnace and is heated to 490°C, it enters the coke tower for coking reaction, and the coke generated by the reaction is deposited. In the coke tower, the coke oil gas enters the fractionation tower to be fractionated into gas and liquid hydrocarbons. The operating conditions and material balance are listed in Table 3.

[0043] As can be seen from Table 3, the yield of liquid hydrocarbons reached 48.5% by weight.

Embodiment 2

[0045] Raw coal B is pulverized into coal powder with a particle size of 100-400 mesh, and super heavy oil is added to the mixer at a weight ratio of 1.94:1, and the oil-coal slurry is obtained after dissolving at 285°C for 64 hours. The oil-coal slurry enters the heating furnace and is heated to After 510°C, it enters the coke tower for coking reaction, the coke generated by the reaction is deposited in the coke tower, and the coked oil gas enters the fractionation tower to be fractionated into gas and liquid hydrocarbons. The operating conditions and material balance are listed in Table 3.

[0046] As can be seen from Table 3, the yield of liquid hydrocarbons reached 33.3% by weight.

Embodiment 3

[0048] Crush the raw coal C into coal powder with a particle size of 100-400 mesh, and put the vacuum residue into the mixer at a weight ratio of 1.0:1, dissolve at 200°C for 24 hours to obtain an oil-coal slurry, and the oil-coal slurry enters the heating furnace for heating After reaching 500°C, it enters the coke tower for coking reaction, the coke generated by the reaction is deposited in the coke tower, and the coked oil gas enters the fractionation tower to be fractionated into gas and liquid hydrocarbons. The operating conditions and material balance are listed in Table 3.

[0049] As can be seen from Table 3, the yield of liquid hydrocarbons reached 42.0% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com