Method for preparing xyio-oligosacchandes by using ultrasonic to treat agricultural wastes

A technology of agricultural waste and xylooligosaccharides, which is applied in the field of preparation of xylooligosaccharides, can solve the problems of high pollution, high cost, and long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

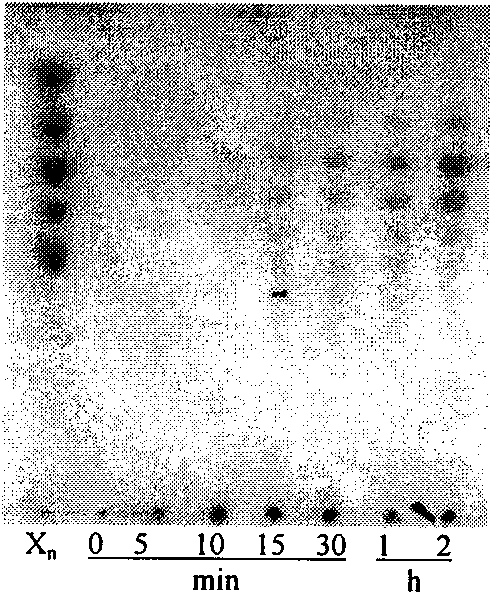

Image

Examples

Embodiment 1

[0028] Step 1: Disperse the corn cob powder particles in a 10% (w / v) NaOH solution at a solid-to-liquid ratio of 1:10, and ultrasonically treat them for 30-40 minutes at 45-60°C and 110-130W; the optimum is 50 ℃, ultrasonic treatment at 120W for 35min;

[0029] Step 2: filtering to remove solids, collecting the filtrate, and adjusting the pH value to slightly acidic with an acidic buffer to obtain a hemicellulose solution;

[0030] Step 3: Add purified Streptomyces rameus endo-xylanase to the above hemicellulose solution to hydrolyze hemicellulose, wherein the amount of enzyme added is 50U / g substrate, and the reaction temperature is 45- 55°C, preferably 50°C, constant temperature shaking enzymatic hydrolysis for 24 hours;

[0031] Step 4: Boil the above solution in boiling water for 10 minutes to inactivate enzymes, centrifuge, separate, collect the supernatant, and then refine through processes such as decolorization, ion exchange, and concentration to obtain xylooligosacch...

Embodiment 2

[0033] Step 1: Disperse the bean stalk powder particles in a 10% (w / v) NaOH solution at a solid-to-liquid ratio of 1:10, and ultrasonically treat them for 30-40 minutes at 60-80°C and 180-200W; the optimum is 70 ℃, ultrasonic treatment at 190W for 35min;

[0034] Step 2: filtering to remove solids, collecting the filtrate, and adjusting the pH value to slightly acidic with an acidic buffer to obtain a hemicellulose solution;

[0035] Step 3: Add purified Streptomyces rameus endo-xylanase to the above hemicellulose solution to hydrolyze hemicellulose, wherein the amount of enzyme added is 50U / g substrate, and the reaction temperature is 45- 55°C, preferably 50°C, constant temperature shaking enzymatic hydrolysis for 24 hours;

[0036] Step 4: Boil the above solution in boiling water for 10 minutes to inactivate enzymes, centrifuge, separate, collect the supernatant, and then refine through processes such as decolorization, ion exchange, and concentration to obtain xylooligosac...

Embodiment 3

[0038] Step 1: Disperse the cottonseed hull powder particles in a 10% (w / v) NaOH solution at a solid-to-liquid ratio of 1:10, and ultrasonically treat them for 30-40 minutes at 60-80°C and 180-200W; the optimum is 70 ℃, ultrasonic treatment at 190W for 35min;

[0039] Step 2: filtering to remove solids, collecting the filtrate, and adjusting the pH value to slightly acidic with an acidic buffer to obtain a hemicellulose solution;

[0040] Step 3: adding purified Streptomyces rameus endo-xylanase to the above hemicellulose solution to hydrolyze hemicellulose, wherein the amount of enzyme added is 50U / g substrate, and the reaction temperature is 4555°C , the optimum temperature is 50°C, constant temperature shaking enzymatic hydrolysis for 24 hours;

[0041] Step 4: Boil the above solution in boiling water for 10 minutes to inactivate enzymes, centrifuge, separate, collect the supernatant, and then refine through processes such as decolorization, ion exchange, and concentration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com