Normal temperature and pressure quick desorption electrolysis method of gold loaded carbon

A technology for desorbing electrolysis and gold-loaded carbon, which is applied in separation methods, chemical instruments and methods, photography techniques, etc., can solve the problems of long desorption time, large equipment investment, high production cost, etc., and achieves fast desorption speed, low desorption temperature, The effect of short production cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

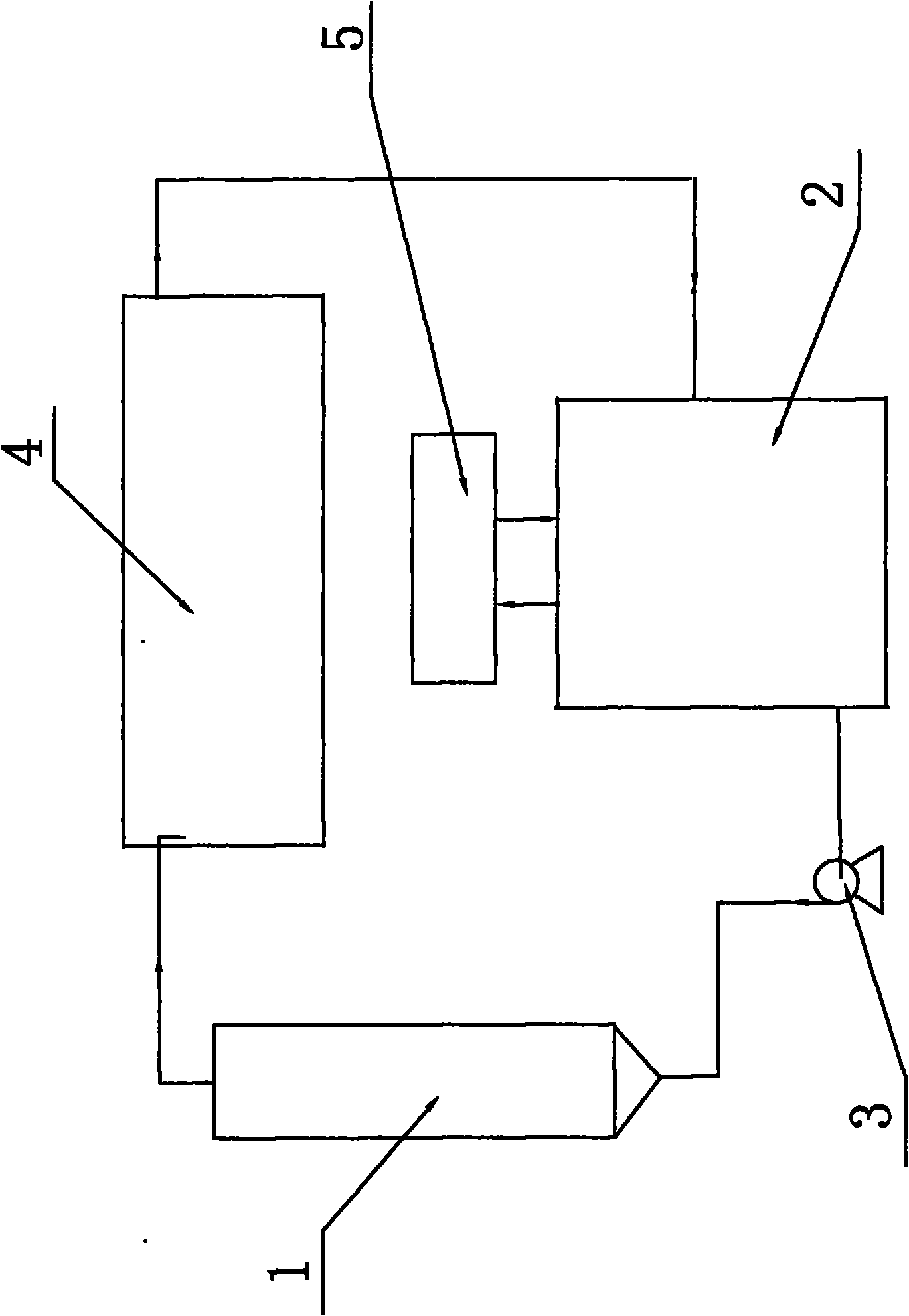

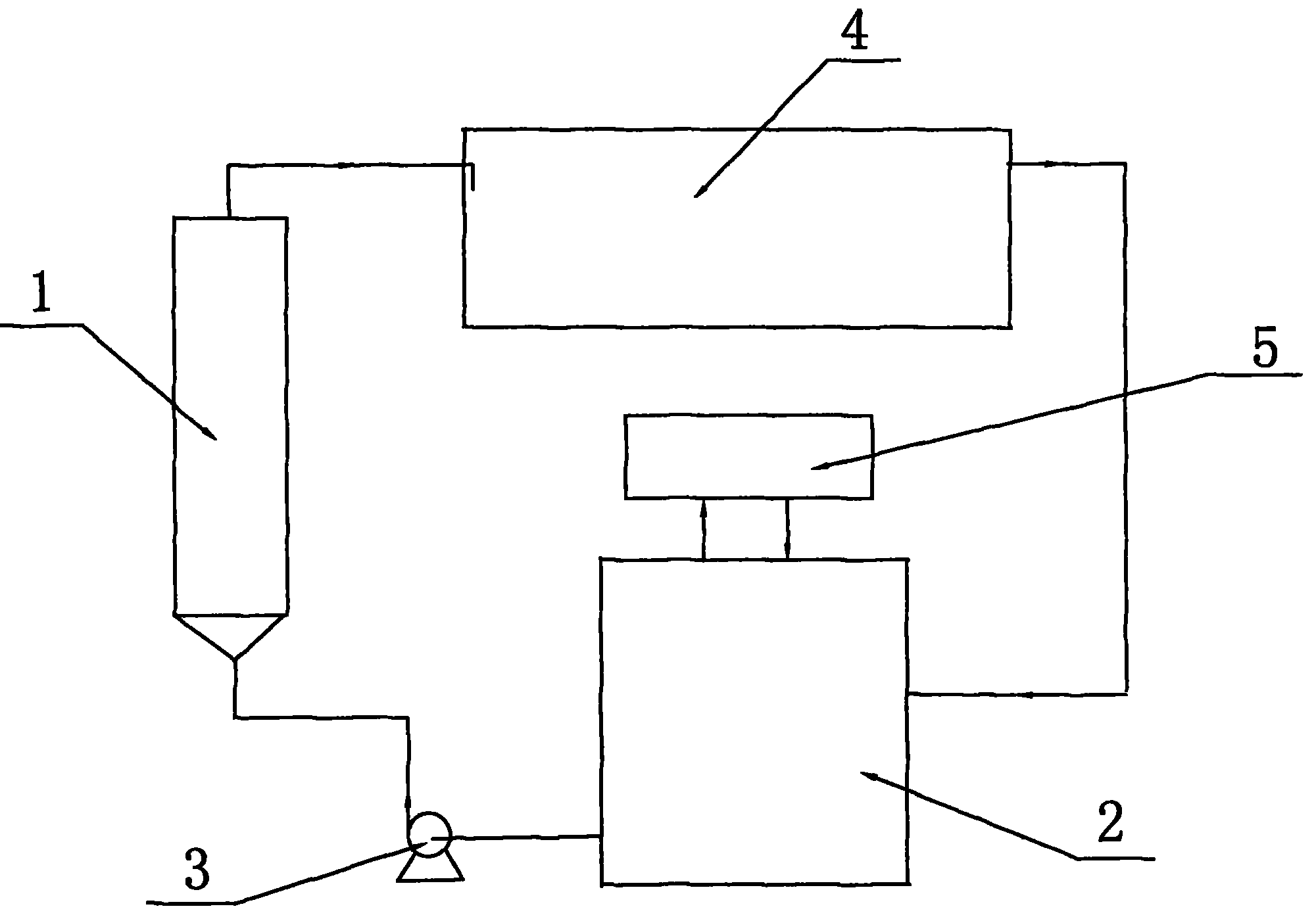

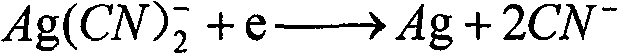

[0026] see figure 1 As shown, the gold-loaded carbon is loaded into the desorption column 1, and the desorption solution with 2 to 5% NaOH and 5 to 10% concentration of desorbent isopropanol is arranged in the circulating heating tank 2, and then passed through the pump 3, in the whole process system Heating and circulating the desorption solution, the desorption temperature is 80°C, and the pressure is 0.1 MPa. The heated desorption solution elutes the gold-loaded carbon, so that the gold enters the eluent as a complex ion, and the obtained noble solution enters the electrolytic cell 4, and is heated under the applied voltage. Under the action, an electrochemical reaction occurs, causing gold to deposit and precipitate at the cathode, thereby recovering gold; the desorption solution after electrolysis is recycled to the heating tank 2, and the heater supplements the heat to reach the desorption temperature, and then circulates through the gold-loaded carbon to elute the gold, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com