Special-purpose emulsifying thickener for paraquat preparation and application method thereof

A technology of emulsifying thickener and application method, which is applied in the direction of herbicide and algicide, application, botany equipment and method, etc., which can solve the problem of loss of viscosity and wall-hanging property, difficulty in adding thickener, and reduction of preparation And other problems, to achieve the effect of enhancing dyeing fastness, bright and beautiful coloring, and increasing adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Formula: fatty alcohol polyoxyethylene ether sodium sulfate 30%; fatty alcohol polyoxyethylene ether 2%; cocamidopropyl sulfobetaine 20%; alkyl polyglycoside APG-0814 3%; methanol 10%; water 35%;

[0036] Configuration method: weigh each component according to the above weight percentage, and set aside; dissolve fatty alcohol polyoxyethylene ether sodium sulfate and fatty alcohol polyoxyethylene ether with methanol, then add water; add cocamidopropyl hydroxysulfobetaine in turn , Alkyl polyglucoside APG-0814, stirred at 15°C-30°C for about 5 minutes to obtain.

[0037] Application method:

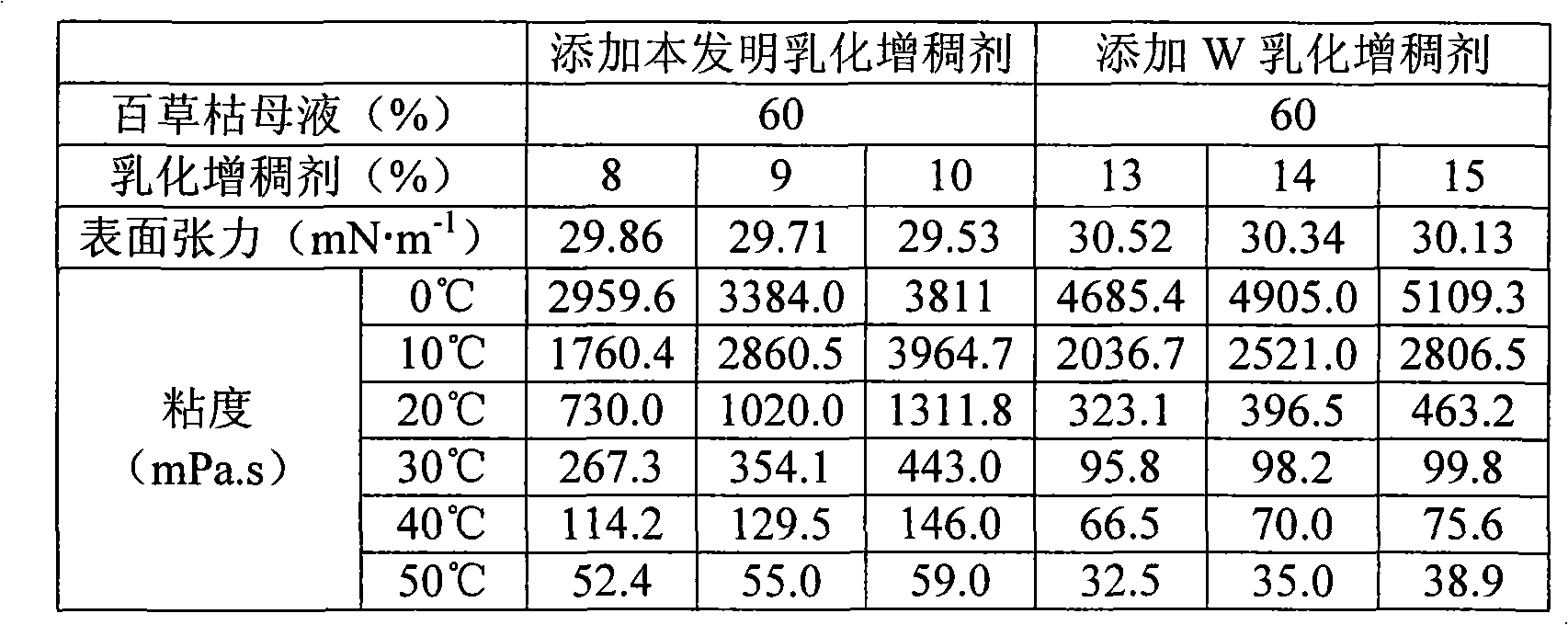

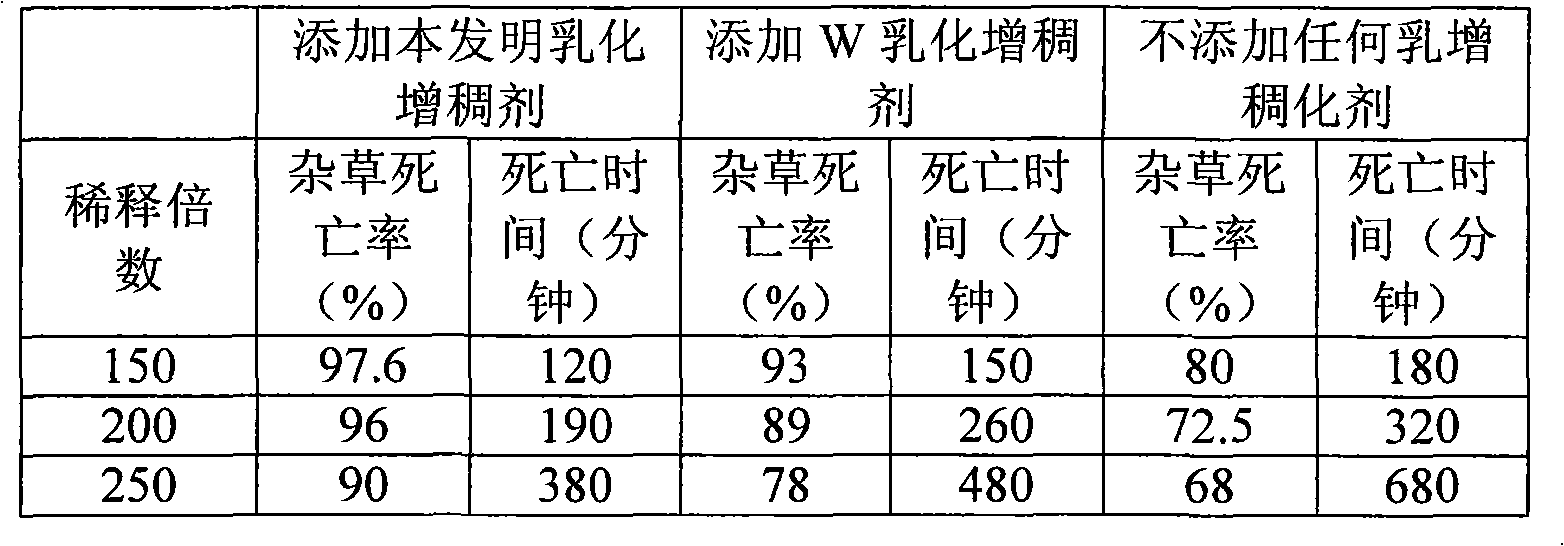

[0038] Formula 1: 20% paraquat cationic preparation: 60% paraquat (dichloride) mother liquor + 8% emulsifying thickener of the present invention + water supplement

[0039] Formula 2: 15% paraquat cationic preparation: 50% paraquat (dichloride) mother liquor + 8% emulsifying thickener of the present invention + 1% salt + water supplement

[0040] Formula 3: 12% paraquat cationic p...

Embodiment 2

[0043] Formula: fatty alcohol polyoxyethylene ether sodium sulfate 35%; fatty alcohol polyoxyethylene ether 1%; cocamidopropyl sulfobetaine 15%; alkyl polyglycoside APG-0814 4%; propylene glycol 12%; water 33%.

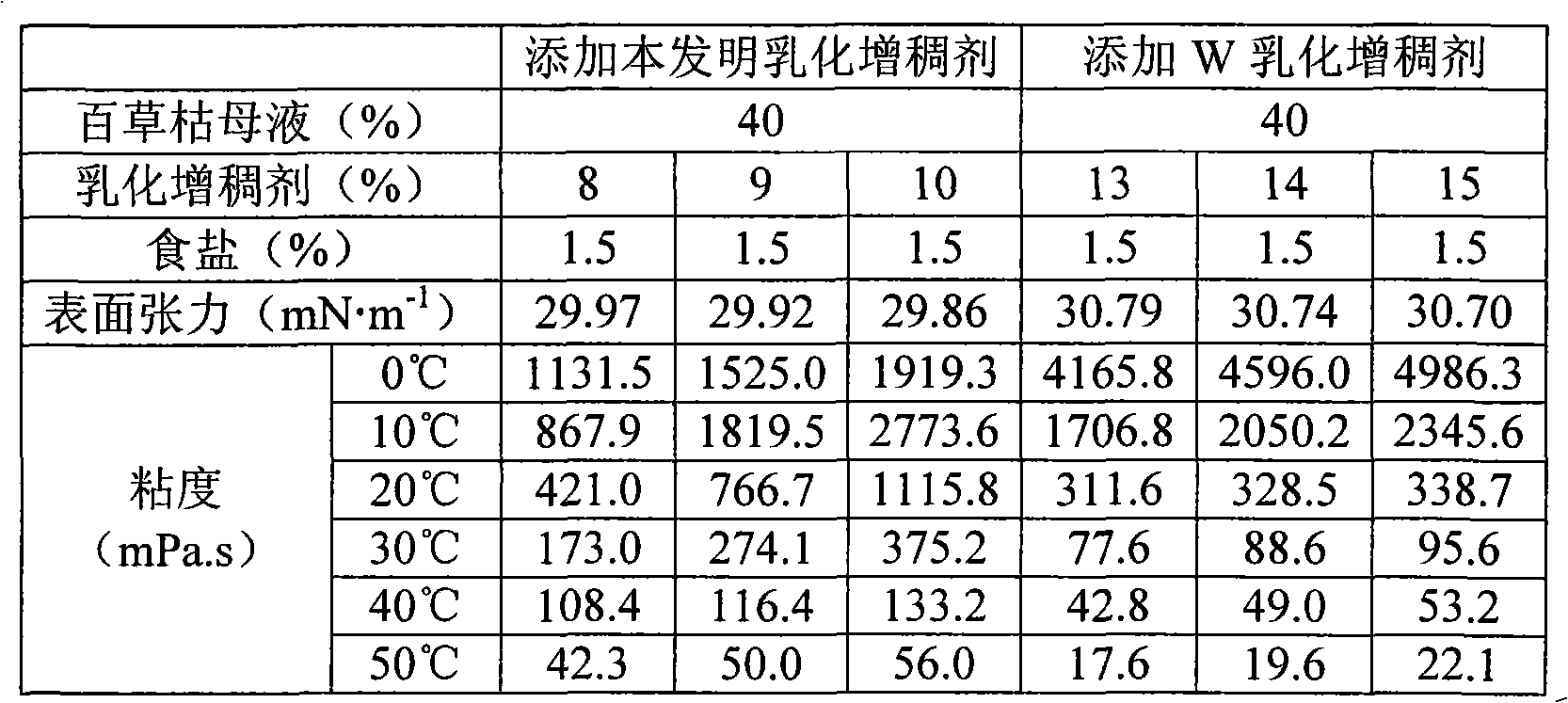

[0044] Configuration and usage method: antifreeze agent propylene glycol replaces methanol, in the application method, 9% of the emulsifying thickener of the present invention is added to the formula of 20% and 12% paraquat cationic preparation, and 1.5% is added to the formula of 12% paraquat cationic preparation The industrial salt used in the formula of 15% paraquat cation, and the rest are the same as in Example 1.

Embodiment 3

[0046] Formula: fatty alcohol polyoxyethylene ether sodium sulfate 39.4%; fatty alcohol polyoxyethylene ether 1.6%; cocamidopropyl sulfobetaine 10%; alkyl polyglycoside APG-1214 2%; propylene glycol 15%; water 32%.

[0047] Configuration and usage method: antifreeze agent propylene glycol instead of methanol, alkyl polyglycoside APG-1214 instead of APG-0814, in the application method, add 8% emulsifying thickener of the present invention to the formula of 15% paraquat cationic preparation, 12% Baicao In the formula of the dry cation preparation, 10% of the emulsifying thickener of the present invention is added, and the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com