Hydrophilic modified method of amphipathic molecule for semi-crystalline polyolefin porous membrane surface

An amphiphilic molecule and molecule-half technology, which is applied in the field of hydrophilic modification of the surface of semi-crystalline polyolefin porous membrane, can solve the problems of unsatisfactory reproducibility of results and sensitivity of polyethylene glycol molecular weight, etc. Uniform hydrophilic modification, improving the effect of surface hydrophilic modification, and improving the effect of enrichment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Clean the high-density polyethylene hollow fiber membrane with acetone for 24 hours, and dry it for later use;

[0025] 2) Immerse the high-density polyethylene hollow fiber membrane in tetralin at a temperature of 70° C. and swell the surface for 5 hours;

[0026] 3) Take out the high-density polyethylene hollow fiber membrane swollen on the surface, and immerse it in stearyl alcohol polyethylene glycol ether (the degree of polymerization of the polyethylene glycol part is 4, AEO- 4) Surface embedding modification in aqueous solution for 1 hour;

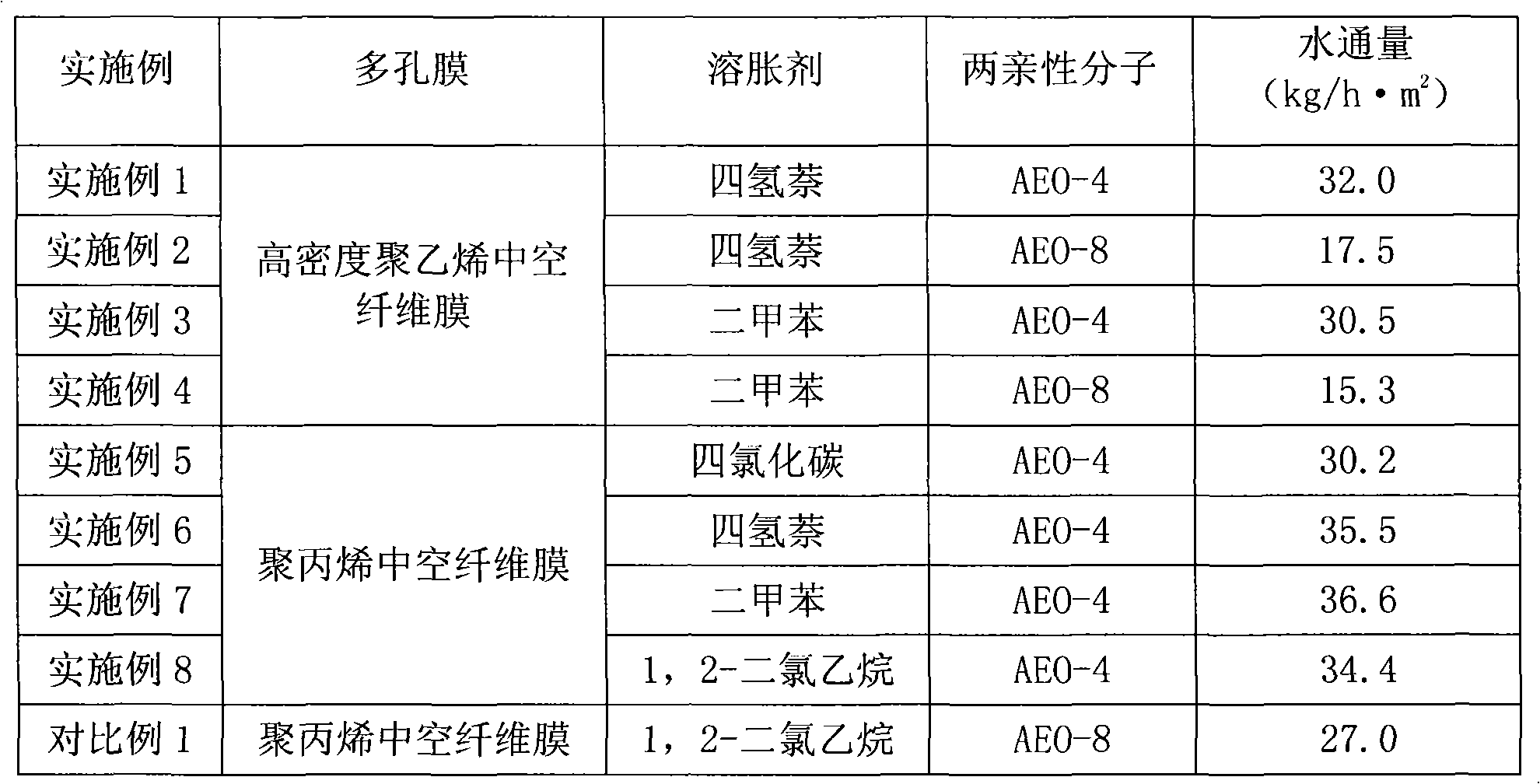

[0027] 4) Deswelling the surface of the high-density polyethylene hollow fiber membrane by vacuum drying, and then cleaning the amphiphilic molecules physically adsorbed on the surface of the membrane with water. The properties of the surface-modified HDPE hollow fiber membranes are shown in Table 1.

Embodiment 2

[0029] 1) Clean the high-density polyethylene hollow fiber membrane with acetone for 24 hours, and dry it for later use;

[0030] 2) Immerse the high-density polyethylene hollow fiber membrane in tetralin at a temperature of 60° C. and swell the surface for 10 hours;

[0031] 3) Take out the high-density polyethylene hollow fiber membrane swollen on the surface, and immerse it in stearyl alcohol polyethylene glycol ether (the degree of polymerization of the polyethylene glycol part is 8, AEO- 8) Surface embedding modification in aqueous solution for 2 hours;

[0032] 4) Deswelling the surface of the high-density polyethylene hollow fiber membrane by vacuum drying, and then cleaning the amphiphilic molecules physically adsorbed on the surface of the membrane with water. The properties of the surface-modified HDPE hollow fiber membranes are shown in Table 1.

Embodiment 3

[0034] 1) Clean the high-density polyethylene hollow fiber membrane with acetone for 24 hours, and dry it for later use;

[0035]2) Immerse the high-density polyethylene hollow fiber membrane in xylene at a temperature of 70° C. and swell the surface for 5 hours;

[0036] 3) Take out the high-density polyethylene hollow fiber membrane swollen on the surface, and immerse it in stearyl alcohol polyethylene glycol ether (the degree of polymerization of the polyethylene glycol part is 4, AEO- 4) Surface embedding modification in aqueous solution for 1 hour;

[0037] 4) Deswelling the surface of the high-density polyethylene hollow fiber membrane by vacuum drying, and then cleaning the amphiphilic molecules physically adsorbed on the surface of the membrane with water. The properties of the surface-modified HDPE hollow fiber membranes are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com