Method for carrying out outer anticorrosion on DN3600 buried steel tube by adopting molten epoxy powder

A technology of fusing epoxy and steel pipes, which is applied in the direction of surface coating liquid devices, induction discharge spraying, special surfaces, etc., can solve the problems of small steel pipe wall thickness/diameter ratio, external anti-corrosion coating adhesion, thickness, Uniformity quality problems, inability to produce products that meet specification requirements, etc., to achieve the effect of ensuring coating quality and optimizing processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

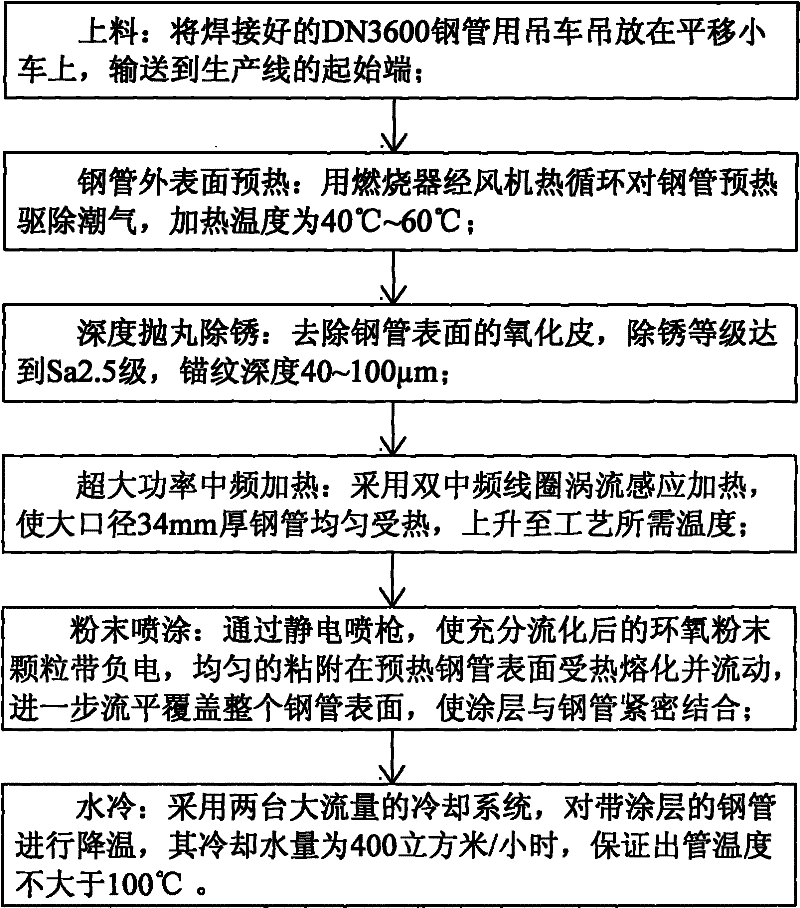

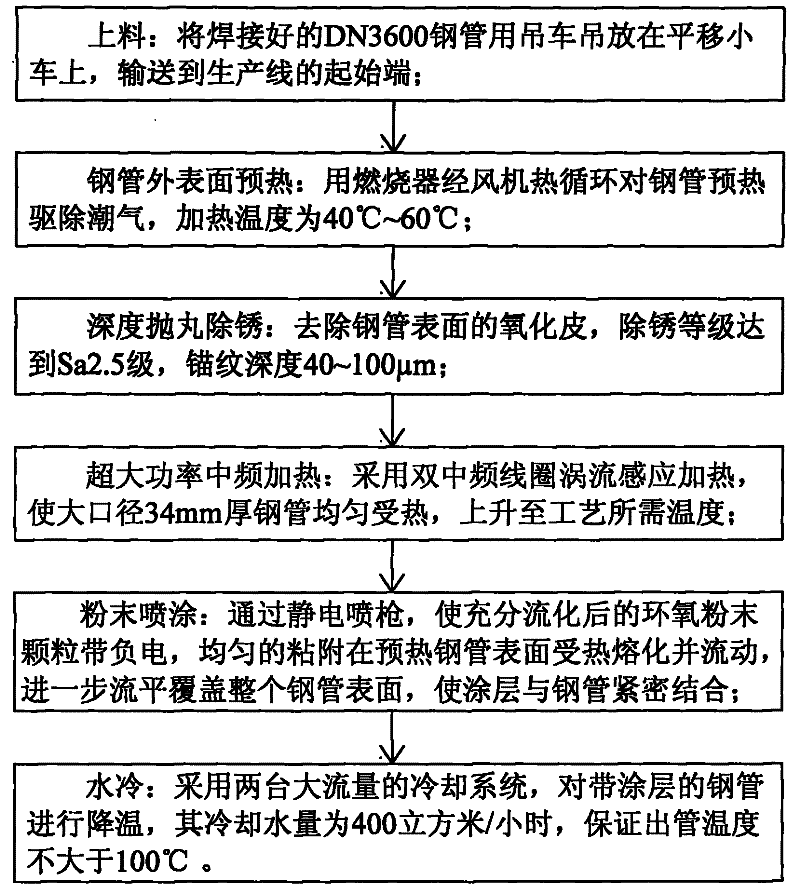

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

[0028] figure 1 Among them, the coating process of the present invention at least includes:

[0029] 1) Loading: hoist the welded DN3600 steel pipe on the translation trolley with a crane, and transport it to the beginning of the production line;

[0030] 2) Preheating of the outer surface of the steel pipe: use a burner to preheat the steel pipe through a fan heat cycle to drive out moisture, and the heating temperature is 40°C to 60°C;

[0031] 3) Depth shot blasting derusting: remove the oxide skin on the surface of the steel pipe, the derusting grade reaches Sa2.5 level, and the depth of the anchor pattern is 40-100 μm;

[0032] 4) Ultra-high power intermediate frequency heating: double intermediate frequency coil eddy current induction heating is used to heat the large-diameter 34mm thick steel pipe evenly and rise to the temperature required by the process;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com