Multi-channel real-time online optical fiber displacement detecting and controlling instrument

A measurement and control instrument and optical fiber technology, applied in the field of intelligent displacement monitoring and control instruments, can solve problems such as inability to adapt to large-scale automated production lines, high testing environment requirements, and complex instrument systems, and achieve novel and unique product concepts and strong redundancy. Sexual, economical and practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

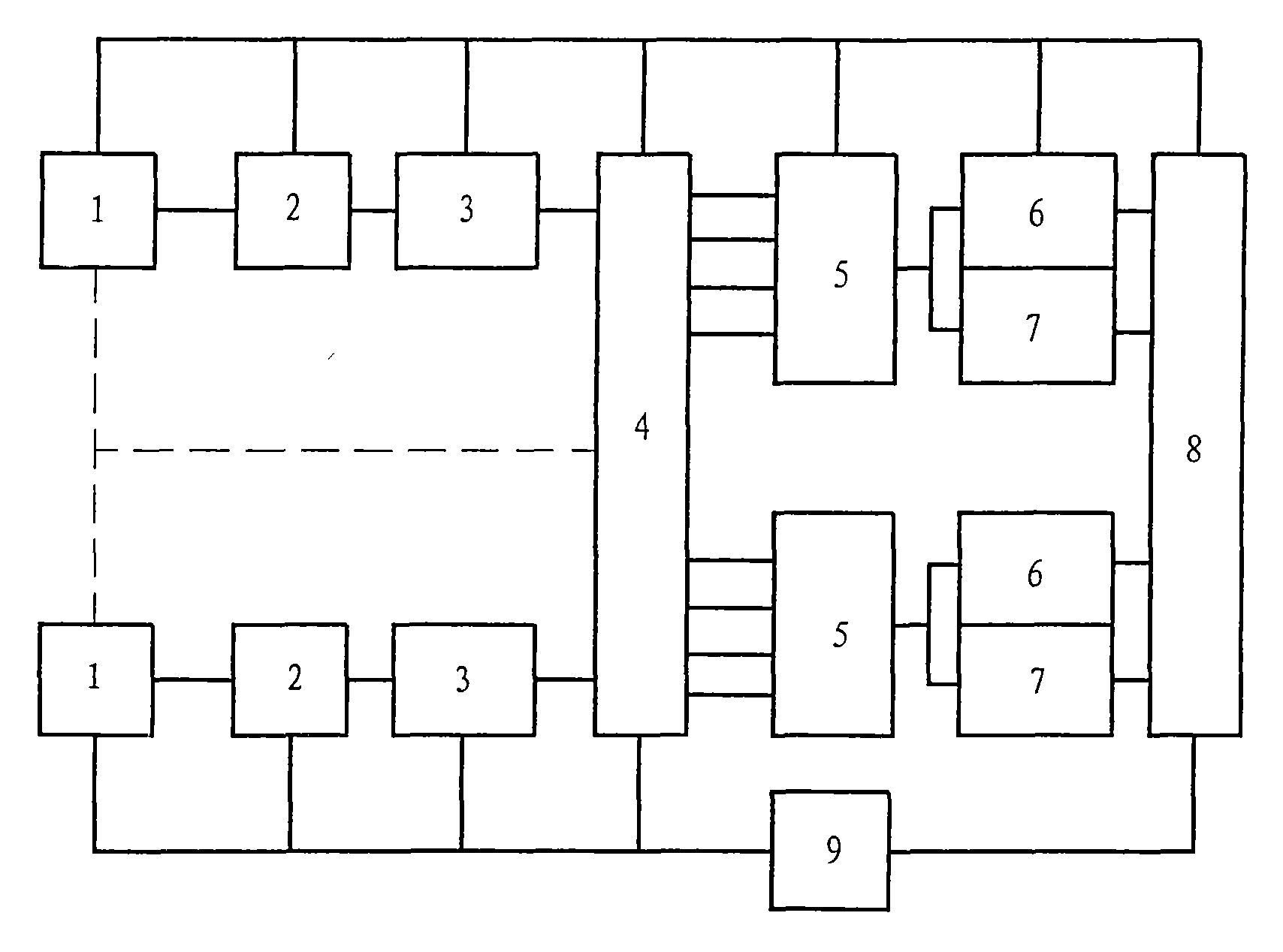

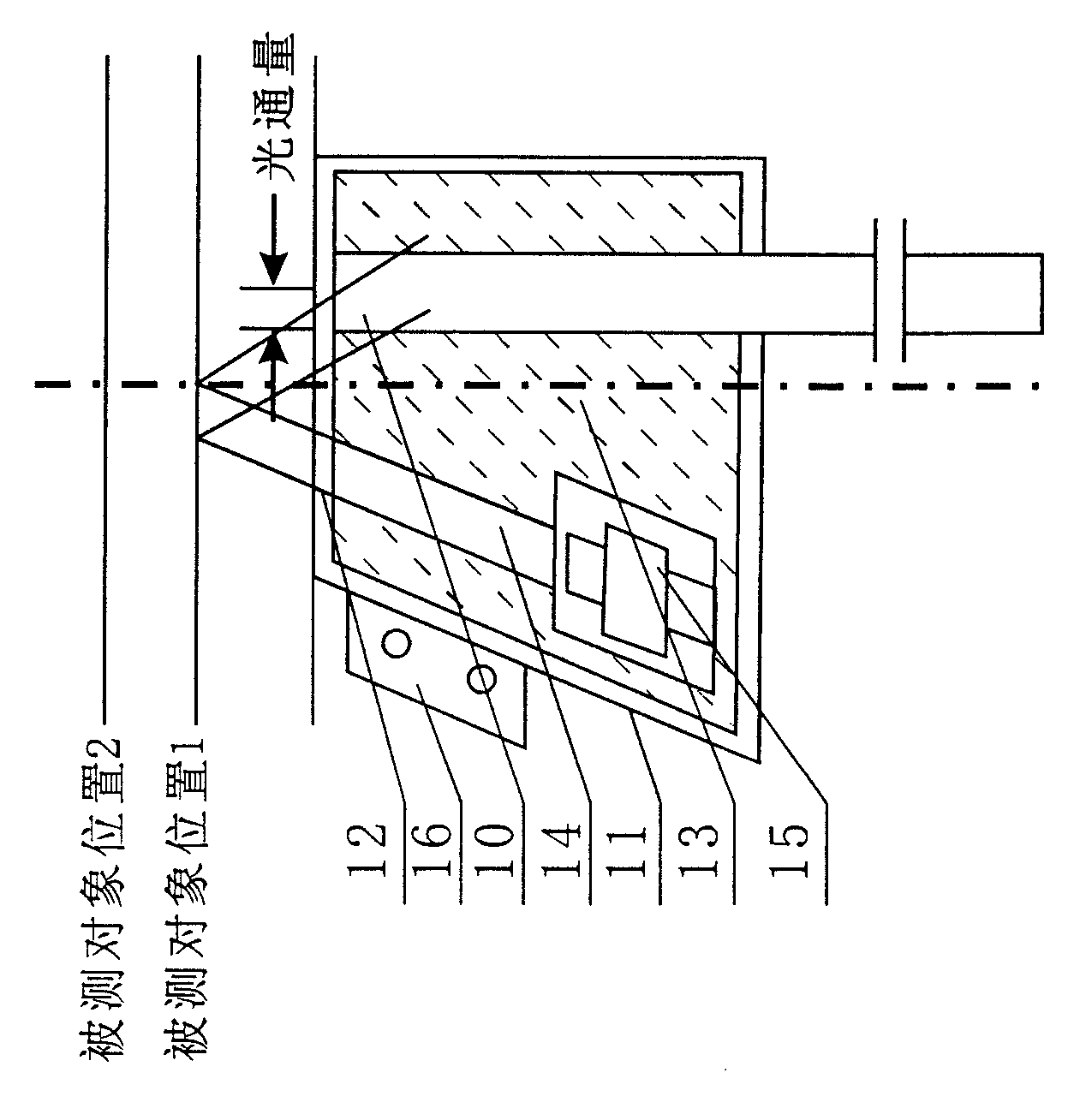

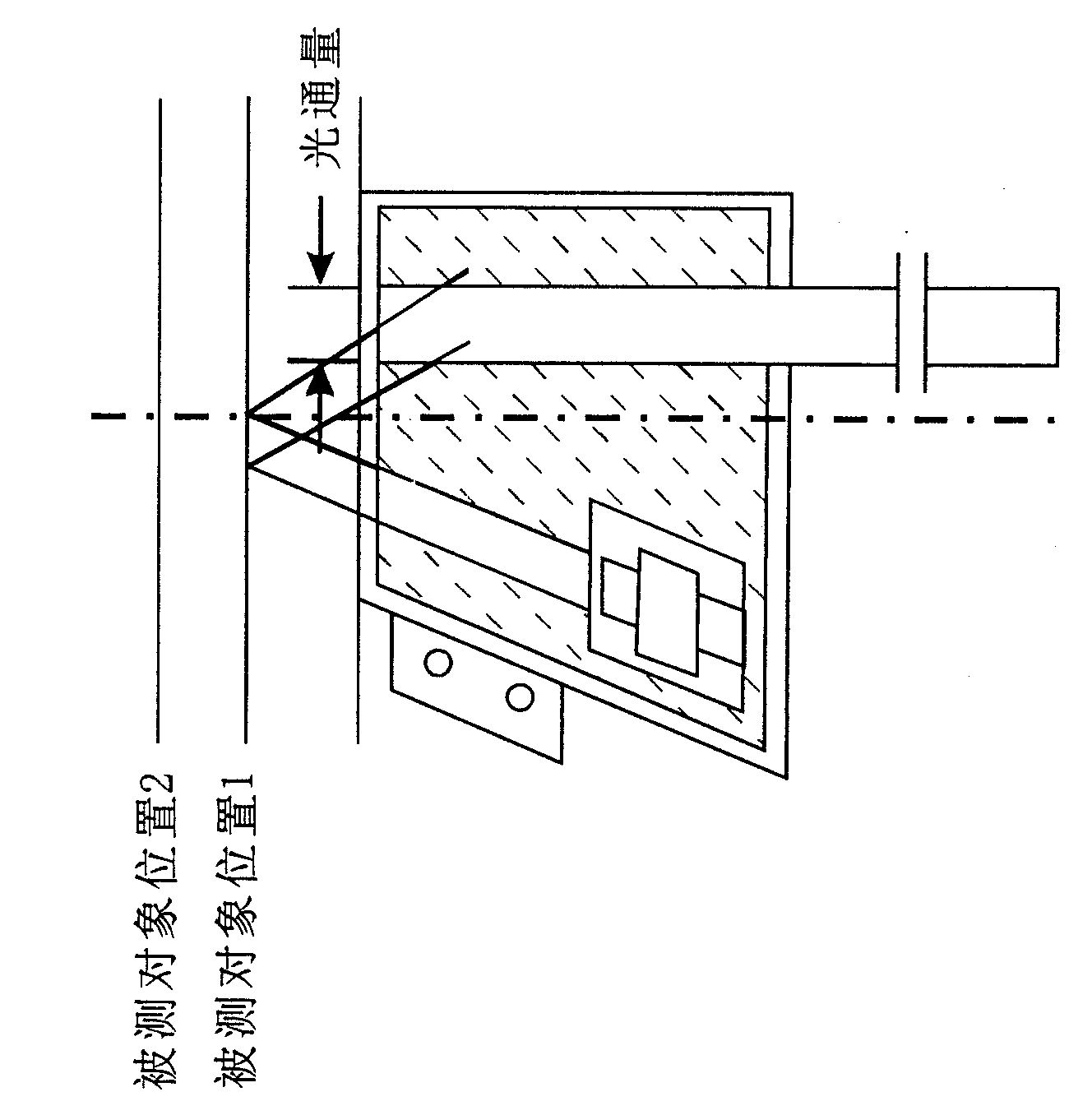

[0026] Depend on Figure 1-Figure 7 The multi-channel real-time online optical fiber displacement measuring and controlling instrument shown is composed of an optical fiber sensor 1, an optical signal reader 2, an analog signal conditioner 3, a transfer switch 4, an analog / digital converter 5, a first-in-first-out buffer 6, The ring buffer 7, the single chip microcomputer and the internal system bus 8, and the digital / analog converter 9 are composed of nine parts. When assembling, install the optical fiber sensor 1 on a fixed object at a specified distance from the measured object, and the other parts are optical signal reader 2, analog signal conditioner 3, conversion switch 4, analog / digital converter 5, first come first Output buffer 6, ring buffer 7, single-chip microcomputer, internal system bus 8, and digital / analog converter 9 are packaged in a rectangular housing as a whole, and are formed by connecting optical fiber sensor 1 through transmission optical fiber 10.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com