Composition containing base asphalt and asphalt composition and preparation method thereof

A technology of asphalt composition and matrix asphalt, which is applied in building structures, building components, building thermal insulation materials, etc., can solve the problems of not being able to simultaneously improve the high and low temperature resistance, aging resistance and flame retardancy of the asphalt composition, and achieve The effect of excellent aging resistance and flame retardancy, good high and low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

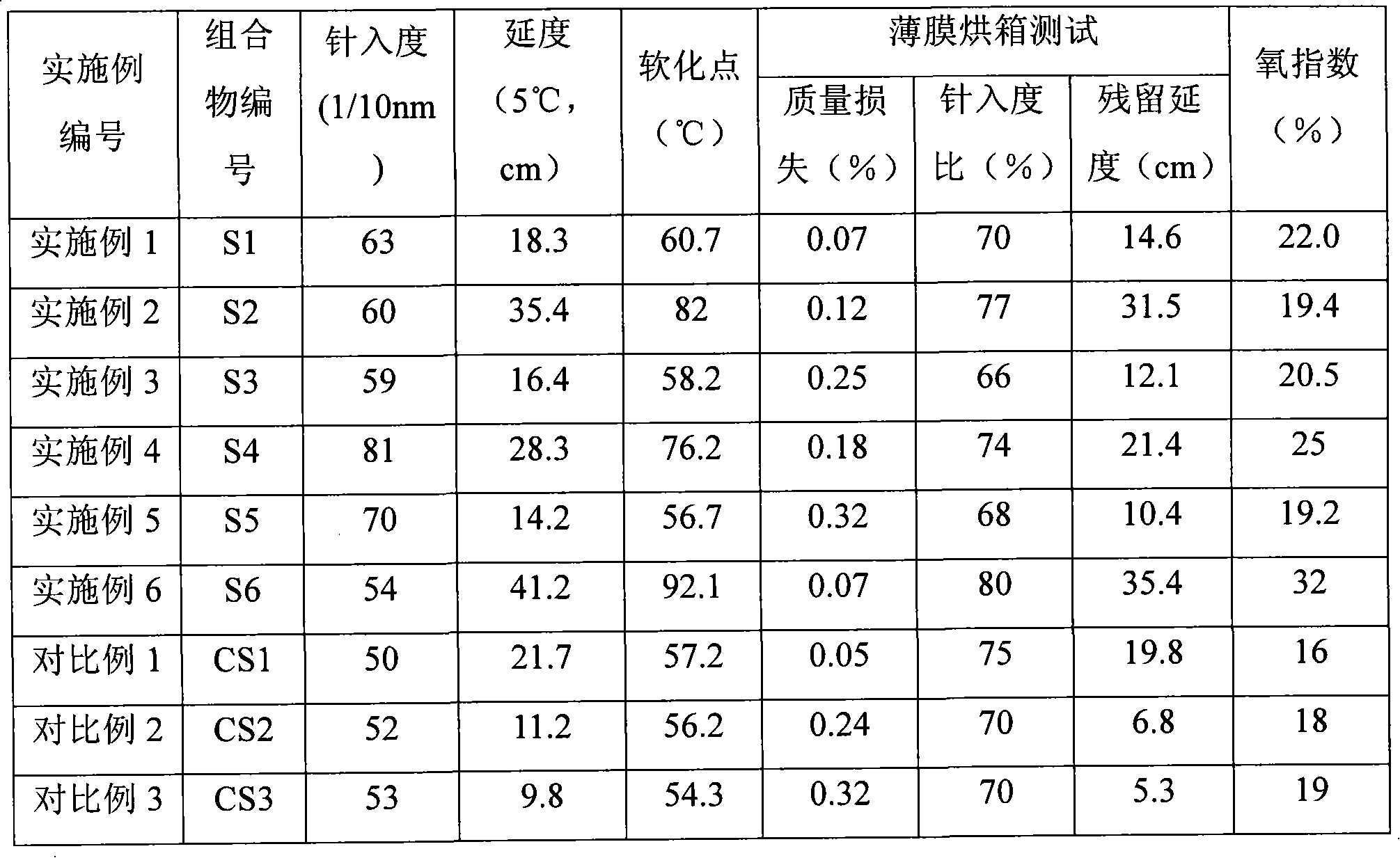

Examples

preparation example Construction

[0023] The preparation method of the asphalt composition provided by the present invention comprises heating the composition containing base asphalt to melt the base asphalt, wherein the composition containing base asphalt is the composition containing base asphalt provided by the present invention.

[0024] The temperature for melting the base asphalt is determined according to the type of base asphalt selected, generally, it is heated to 80-220°C, preferably 100-200°C.

[0025] Preferably, the base asphalt-containing composition is heated to melt the base asphalt, and then kept in a shearing machine at a speed of 1000-6000 rpm for 0.5-4.0 hours to obtain a modified asphalt composition.

[0026] The asphalt composition provided by the invention is a product obtained by heating a composition containing base asphalt to melt the base asphalt, wherein the composition containing base asphalt is the composition containing base asphalt provided by the present invention.

Embodiment 1

[0029] This example is used to illustrate the asphalt composition provided by the present invention and its preparation method.

[0030] At 25°C, 60 parts by weight of chlorinated polyethylene (Weifang Yaxing) with a degree of chlorination of 35% by weight and a weight-average molecular weight of 100,000 were added to the mill (produced by Jiangdu Kaiyuan Experimental Machinery Factory, model KY6008). Chemical Co., Ltd.) and 0.5 parts by weight of organotin (tin methyl mercaptide SS218), and then add 39.5 parts by weight of dioctyl phthalate (Beijing Chemical Reagent Company). After further mixing for 30 minutes, 100 parts by weight of the mixture M1, namely the modifier, was obtained, the composition of which is shown in Table 2.

[0031]Add 86 parts by weight of bitumen A1 (produced by Sinopec Zhenhai Petrochemical Plant, ZH-70I) into a 1-liter reactor, and heat it to 180°C, add 7.5 parts by weight of the mixture M1 obtained above and 0.5 parts by weight of anhydrous aluminu...

Embodiment 2

[0039] This example is used to illustrate the asphalt composition provided by the present invention and its preparation method.

[0040] At 25°C, add 50 parts by weight of chlorinated polyethylene (Weifang Yaxing) with a chlorination degree of 35% by weight and a weight-average molecular weight of 100,000 in an open mill (produced by Jiangdu Kaiyuan Experimental Machinery Factory, model KY6008). Chemical Co., Ltd.) and 1 part by weight of tribasic lead sulfate (Beijing Dahongmen Chemical Raw Materials Company), and 49 parts by weight of dioctyl phthalate (Beijing Chemical Reagent Company). After further mixing for 30 minutes, 100 parts by weight of the mixture M2, namely the modifier, was obtained, the composition of which is shown in Table 2.

[0041] In a 1-liter reactor, add 76.5 parts by weight of pitch A2 (produced by Sinopec Maomen Petrochemical Plant, MM-70I), and heat to 160°C, add 20 parts by weight of the above-mentioned mixture M2 and 1.5 parts by weight of iron tri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com