Method for preparing non-enzymatic glucose sensor from nickel nano-particle/carbon nano-fiber composite material

A glucose sensor and carbon nanofiber technology, which is applied in the field of nickel nanoparticle/carbon nanofiber composite materials to prepare non-enzymatic glucose sensors, can solve the problems that the application research of electrospun materials is in its infancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

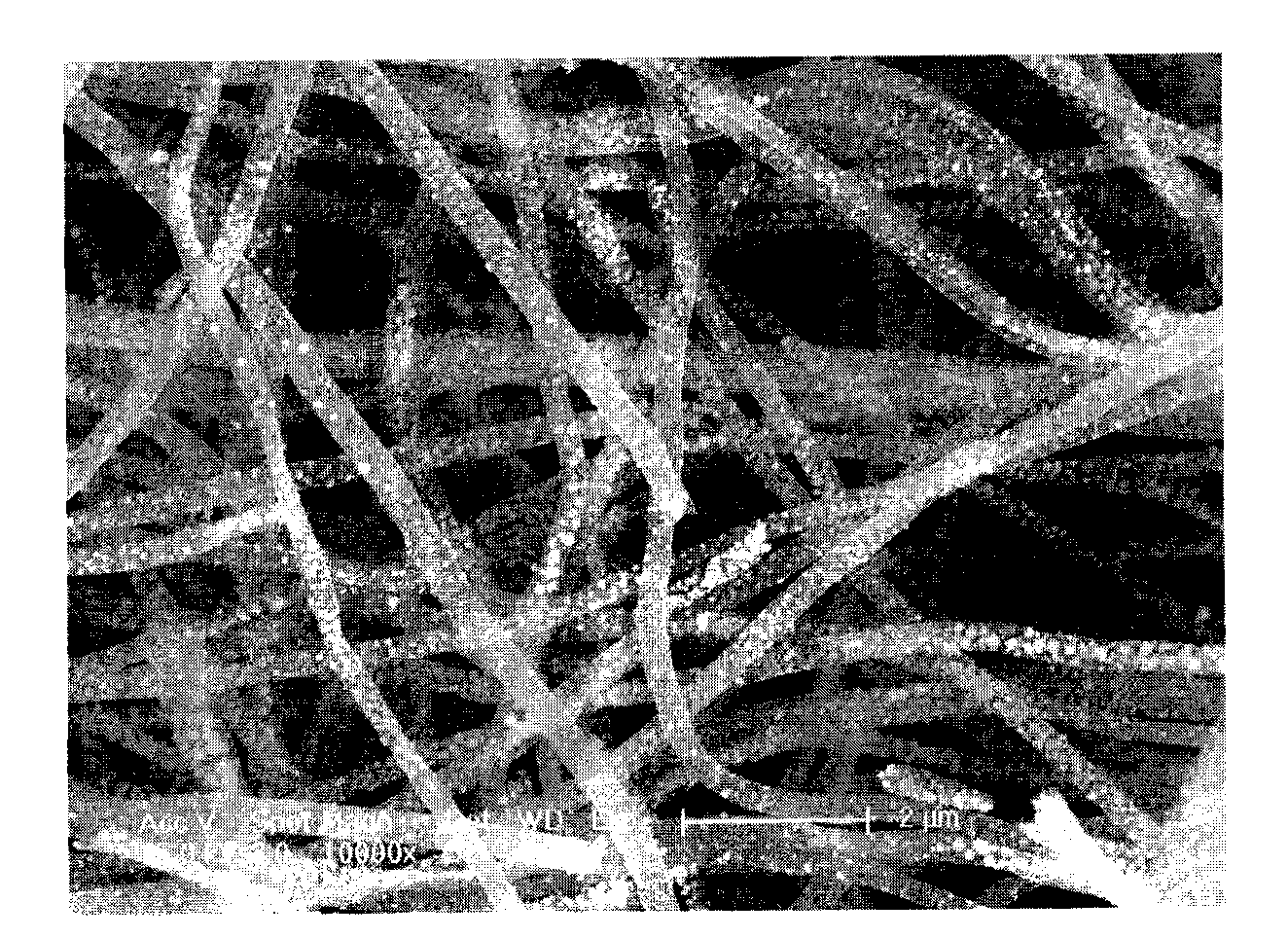

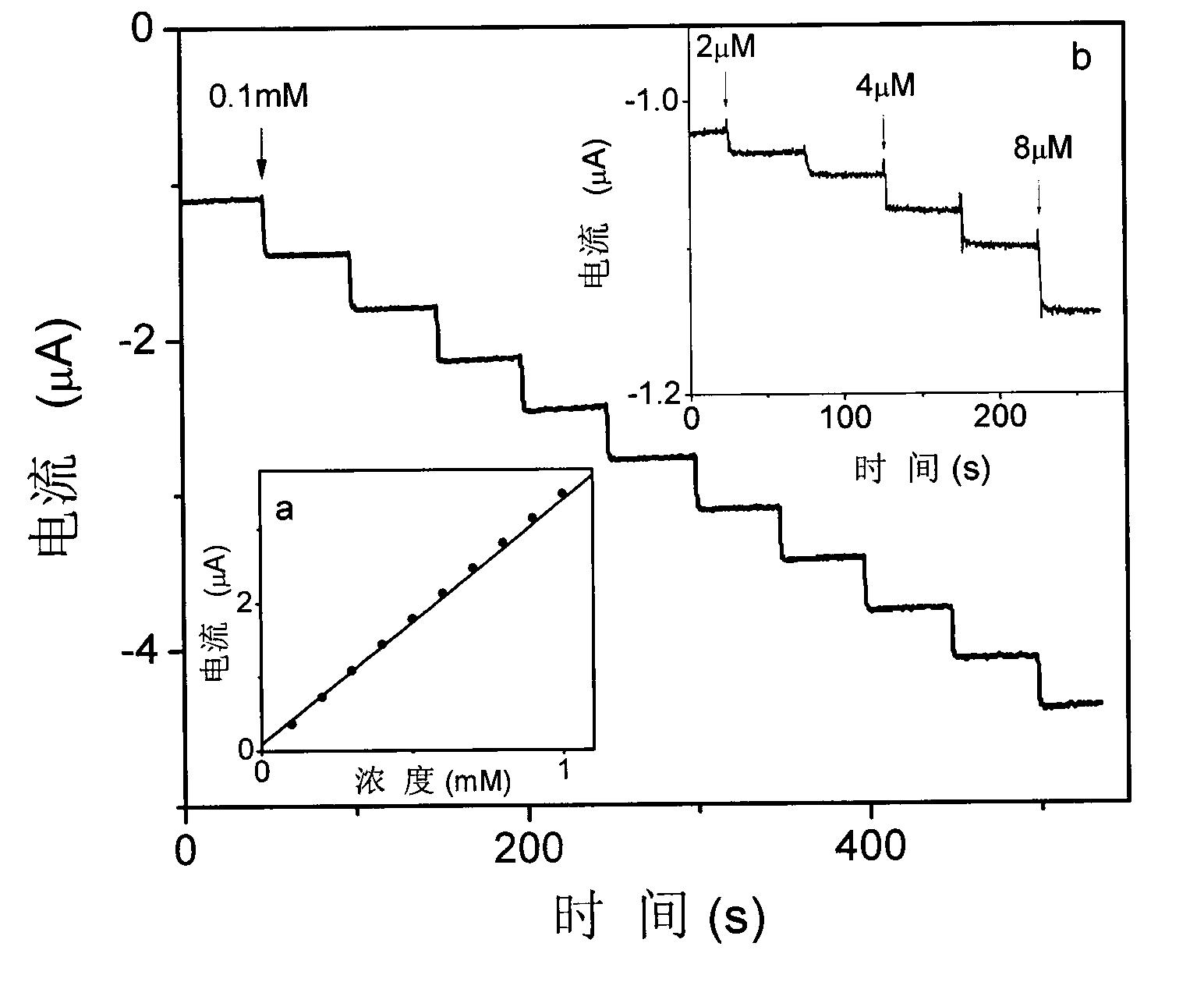

[0024] Example 1. Preparation of non-enzymatic glucose sensor by nickel nanoparticle / carbon nanofiber composite

[0025] 1) Preparation of electrospinning solution: 8wt.% polyacrylonitrile and 3wt.% nickel acetylacetonate were dissolved in the solvent dimethylformamide to obtain a uniform mixed solution;

[0026] 2) Electrospinning process: the homogeneous mixed solution obtained in step 1) is electrospun under an electric field strength of 80kV / m, the distance between the spinneret and the collecting plate is 20cm, and the applied voltage is 20kV, thereby obtaining polypropylene Nitrile / nickel acetylacetonate composite fiber;

[0027] 3) annealing the composite fiber obtained in step 2) at 200° C. for 2 hours, thereby partially oxidizing the polyacrylonitrile fiber;

[0028] 4) Raise the temperature to 200°C at a rate of 1°C / min, and keep at this temperature for 1h in a nitrogen environment to stabilize the fiber morphology;

[0029] 5) Raise the temperature to 400°C at a r...

Embodiment 2

[0039] Example 2. Preparation of non-enzymatic glucose sensor by nickel nanoparticle / carbon nanofiber composite

[0040] 1) Preparation of electrospinning solution: 10wt.% polyacrylonitrile and 5wt.% nickel acetylacetonate were dissolved in the solvent dimethylformamide to obtain a uniform mixed solution;

[0041] 2) Electrospinning process: the homogeneous mixed solution obtained in step 1) is electrospun under an electric field strength of 100kV / m, the distance between the spinneret and the collecting plate is 30cm, and the applied voltage is 30kV, thereby obtaining polypropylene Nitrile / nickel acetylacetonate composite fiber;

[0042] 3) annealing the composite fiber obtained in step 2) at 230° C. for 3 hours, thereby partially oxidizing the polyacrylonitrile fiber;

[0043] 4) Raise the temperature to 300°C at a rate of 2°C / min, and keep at this temperature for 2 hours in a nitrogen environment to stabilize the fiber morphology;

[0044] 5) Heating up to 500°C at a rate ...

Embodiment 3

[0053] Example 3, Nickel Nanoparticle / Carbon Nanofiber Composite Preparation of Non-enzymatic Glucose Sensor

[0054] 1) Preparation of electrospinning solution: 12wt.% polyacrylonitrile and 7wt.% nickel acetylacetonate were dissolved in the solvent dimethylformamide to obtain a uniform mixed solution;

[0055] 2) Electrospinning process: the homogeneous mixed solution obtained in step 1) is electrospun under an electric field strength of 120kV / m, the distance between the spinneret and the collecting plate is 40cm, and the applied voltage is 40kV, thereby obtaining polypropylene Nitrile / nickel acetylacetonate composite fiber;

[0056] 3) annealing the composite fiber obtained in step 2) at 250° C. for 4 hours, thereby partially oxidizing the polyacrylonitrile fiber;

[0057] 4) Raise the temperature to 400°C at a rate of 3°C / min, and keep at this temperature for 3 hours in a nitrogen environment to stabilize the fiber morphology;

[0058] 5) The temperature was raised to 600...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com