All-fiber filter based on thin-core fibers

A thin-core fiber, all-fiber technology, applied in the direction of cladding fiber, optical waveguide light guide, etc., can solve the problems of no practical value, poor mechanical strength, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

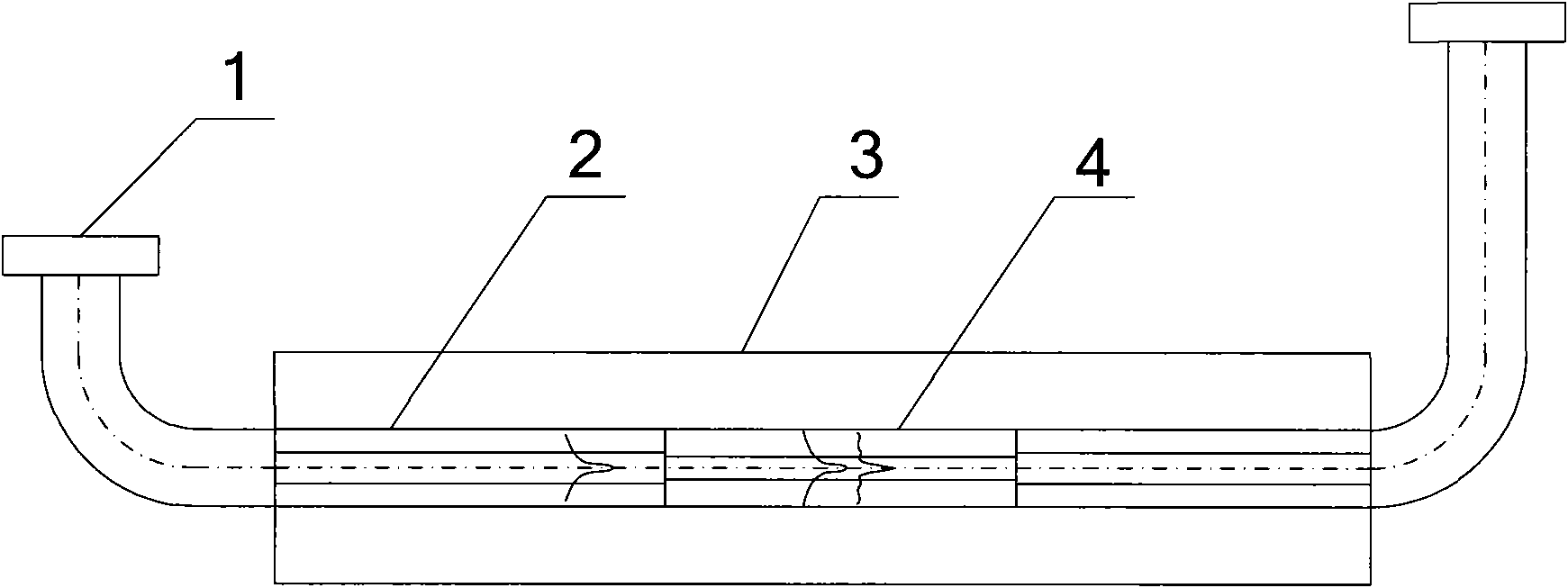

[0012] Such as figure 1 As shown, the thin-core optical fiber filter includes a packaging box 3, and the single-mode optical fiber component is arranged through the packaging box 3, and the two ends of the single-mode fiber component are connected to the flange 1 respectively. The single-mode optical fiber assembly includes three sections of single-mode optical fiber in series, wherein the single-mode optical fiber at both ends adopts a standard single-mode optical fiber 2 (Corning SMF28, core diameter 6.06 μm), and the single-mode optical fiber in the middle section adopts a thin-core single-mode optical fiber 4 (Nufern 460-HP, core diameter 3.30 μm, cut-off wavelength 450nm), three sections of single-mode fiber are coaxially arranged, and the two ends of the thin-core single-mode fiber 4 are respectively fused with one end of two sections of standard single-mode fiber 2 . The filter is respectively connected to the broadband light source and the spectrometer through the flan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com