Fused high-iron ferriporphyrin mullite recombined high-dense brick and manufacture method thereof

A mullite and recombination technology, applied in the field of refractory materials, can solve the problems of affecting service life, surface and internal cracks, etc., and achieve high production efficiency, no gas spallation, and good compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

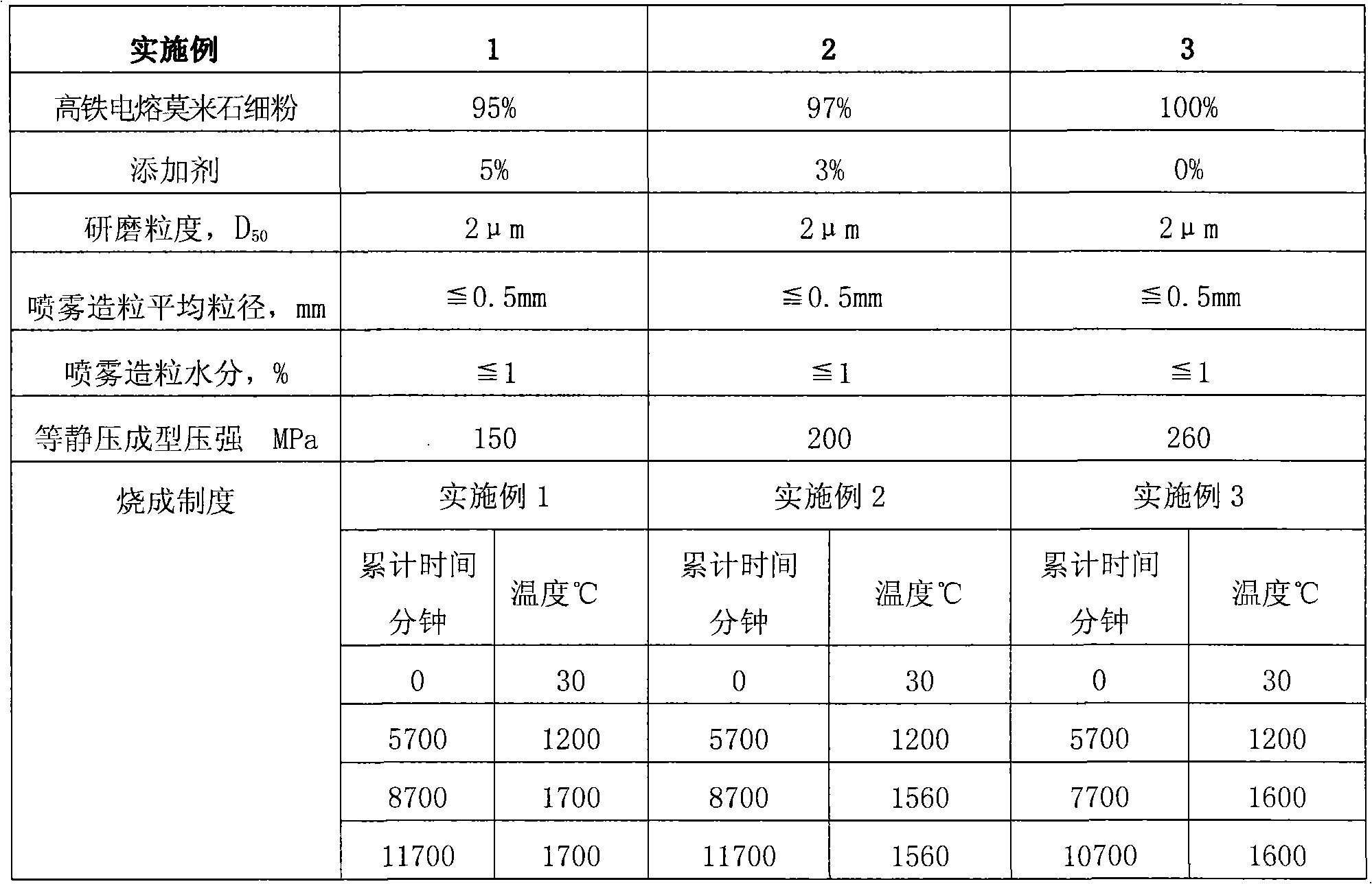

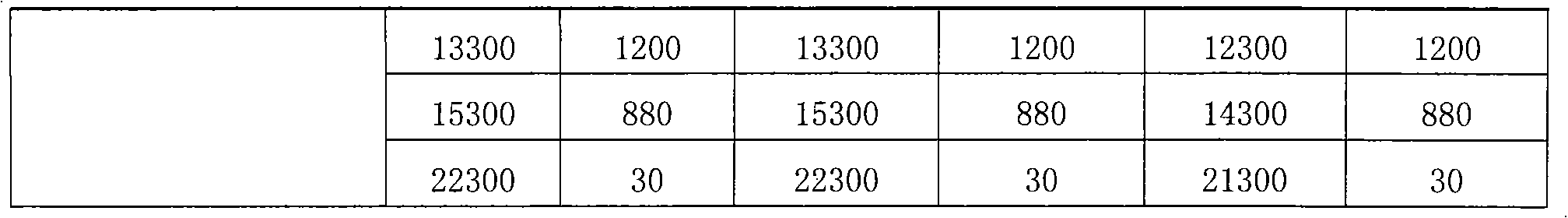

[0022] 1. Raw material ratio and process parameters

[0023] Table 1 raw material ratio and process parameter table

[0024]

[0025]

[0026] Second, the process steps:

[0027] 1) Raw material ratio: According to Table 1 ingredients

[0028] 2) Raw material grinding

[0029] The fine powder of high-iron fused mullite with a particle size of 200 mesh and water are added to a stirring mill for wet grinding to form a slurry with a particle size of D50=5±3 μm.

[0030] 3) Spray granulation: The slurry enters the spray granulator to discharge water to make granulated powder with a particle size of 0.1-0.5mm.

[0031] 4) Forming: forming with a flexible mold.

[0032] 5) Firing: Firing in a kiln with precise temperature control, the firing system is shown in Table 1.

[0033] 3. The physical and chemical indicators of the product: as shown in the table below

[0034] Table 2: Product physical and chemical parameters table

[0035] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com