Hollow spherical valve plug and manufacturing method thereof

A manufacturing method and technology for spherical valves, which are applied to valve devices, cocks including cut-off devices, engine components, etc., can solve problems such as affecting the service life of valve plugs, unable to be used as raw materials, spherical valve plug wear, etc., to achieve enhanced service life, The effect of strong practicability and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

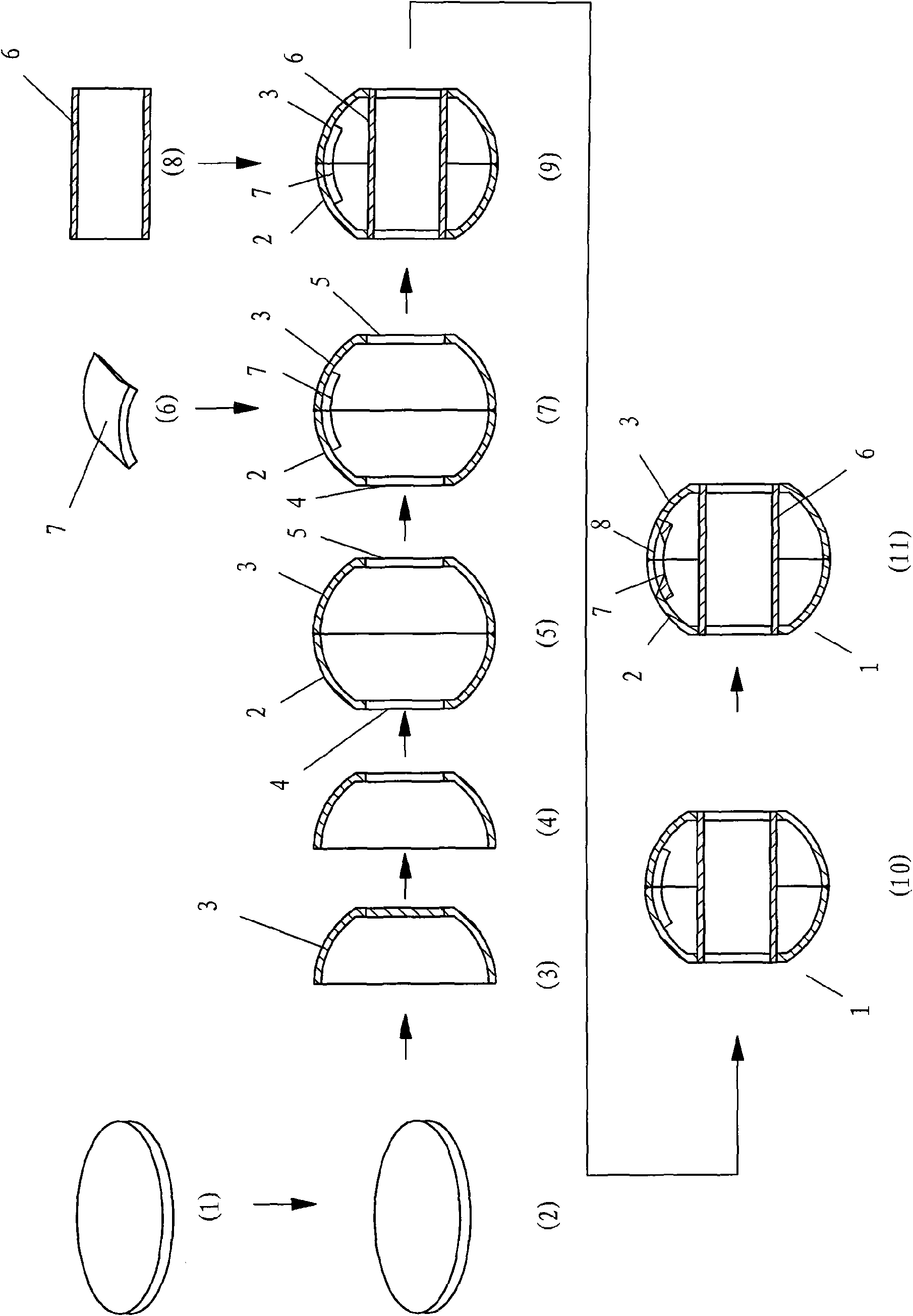

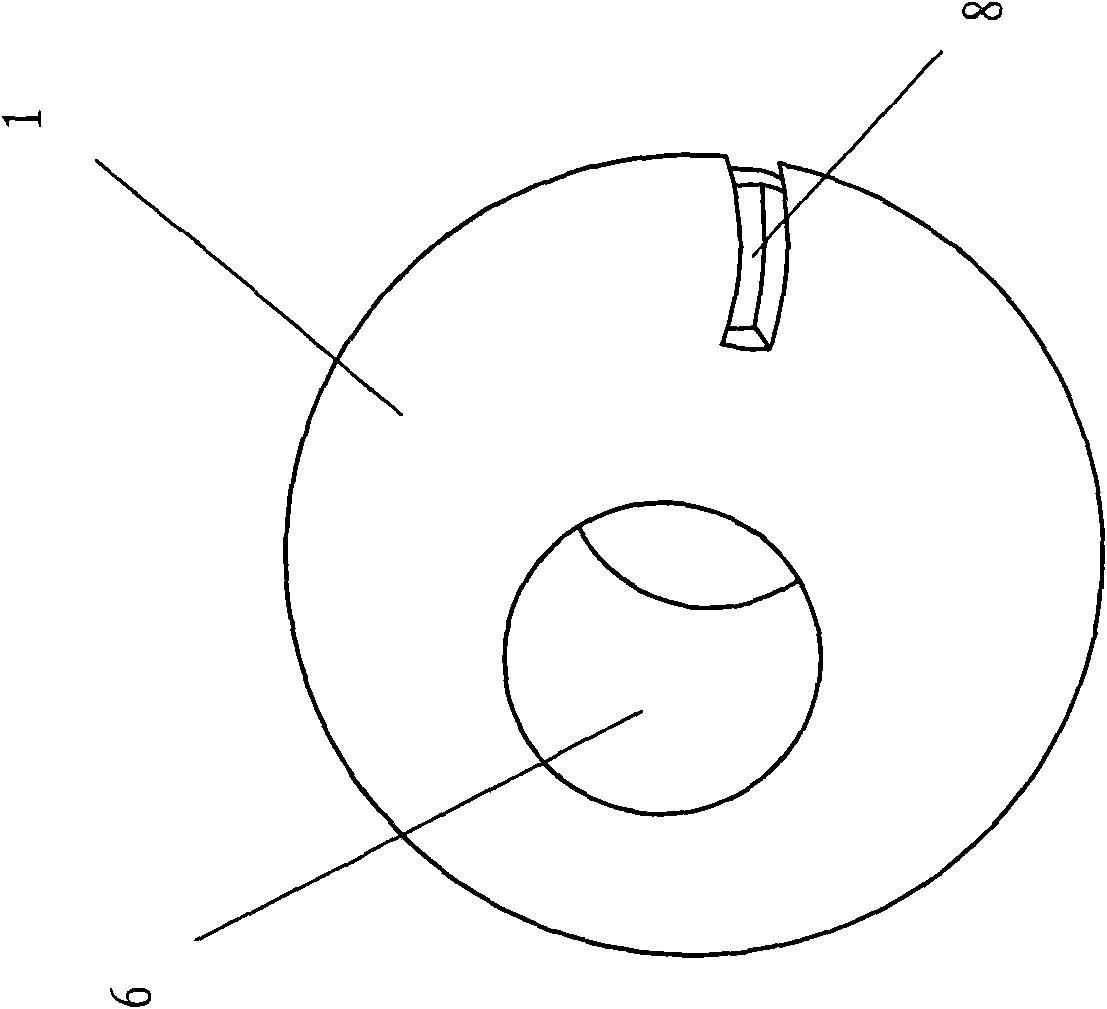

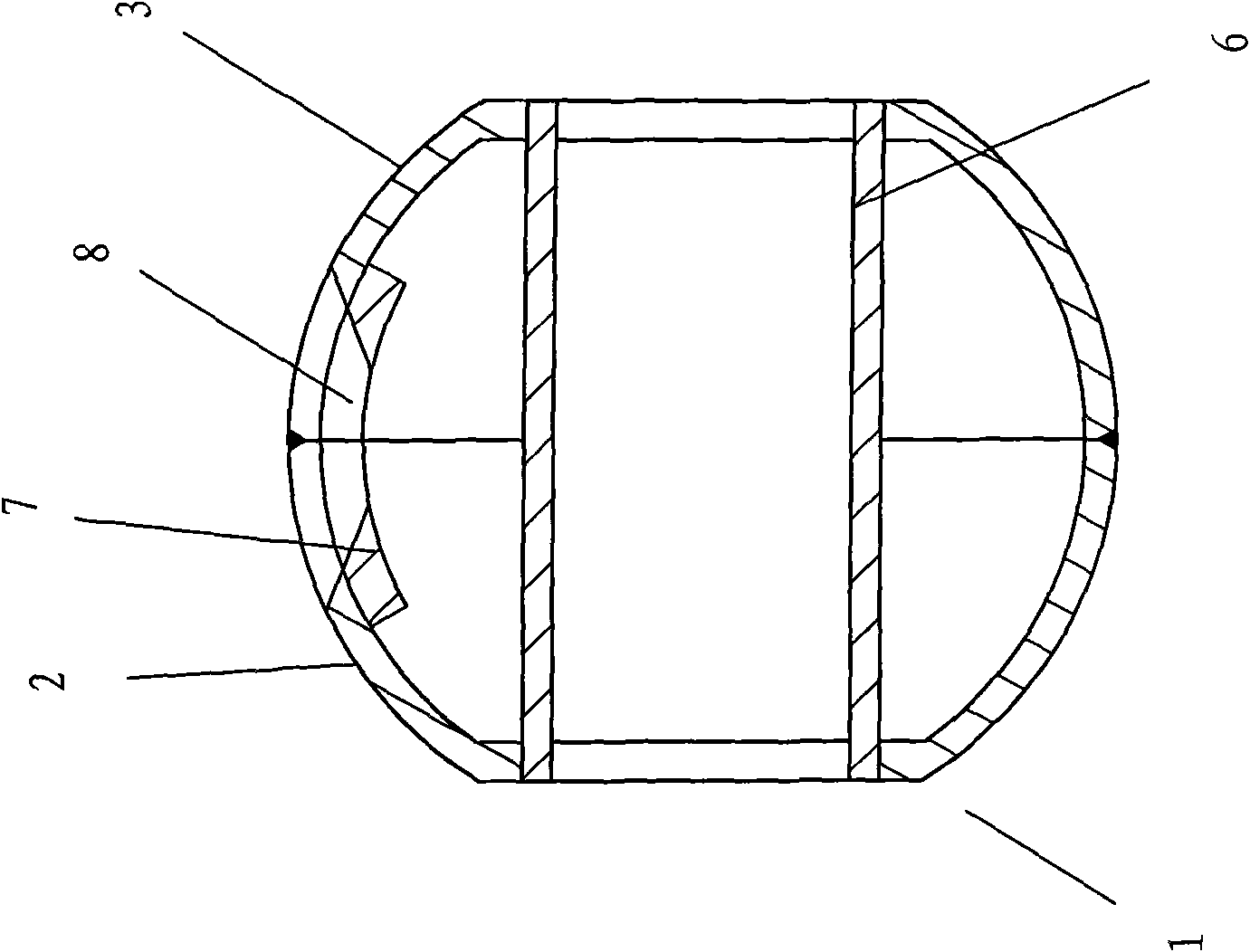

[0021] refer to figure 1 , is the manufacture method of a kind of hollow spherical valve plug of the present invention, and it comprises the following steps:

[0022] a. Use 304 stainless steel sheet material with a thickness of 3-5mm to cut and make it into a circular plate blank, as shown in (1);

[0023] b. Put the blank into the heating furnace, raise the temperature to 800°C within 1 hour and keep the temperature constant for 0.5 hours, then cool it to room temperature naturally, and anneal for stress relief, as shown in (2);

[0024] c. The blank is formed by spinning or drawing respectively to form a hollow left hemisphere 2 and a right hemisphere 3, as shown in (3);

[0025] d. Process welding grooves and perforations 4 and 5 on the left hemisphere 2 and the right hemisphere 3, as shown in (4);

[0026] e, welding the left hemisphere 2 and the right hemisphere 3 into one body to form a hollow spherical main body 1, as shown in (5);

[0027] f. Using 304 stainless st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com