Preparation method for metal base fuel battery bipolar plate with hydrophobicity

A fuel cell and metal-based technology, which is applied to fuel cell components, battery electrodes, metal material coating technology, etc., can solve the problems of battery performance degradation, easy accumulation of water and gas, flow field blockage, etc., and achieve simple process, Good electrical conductivity and water repellency, excellent corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

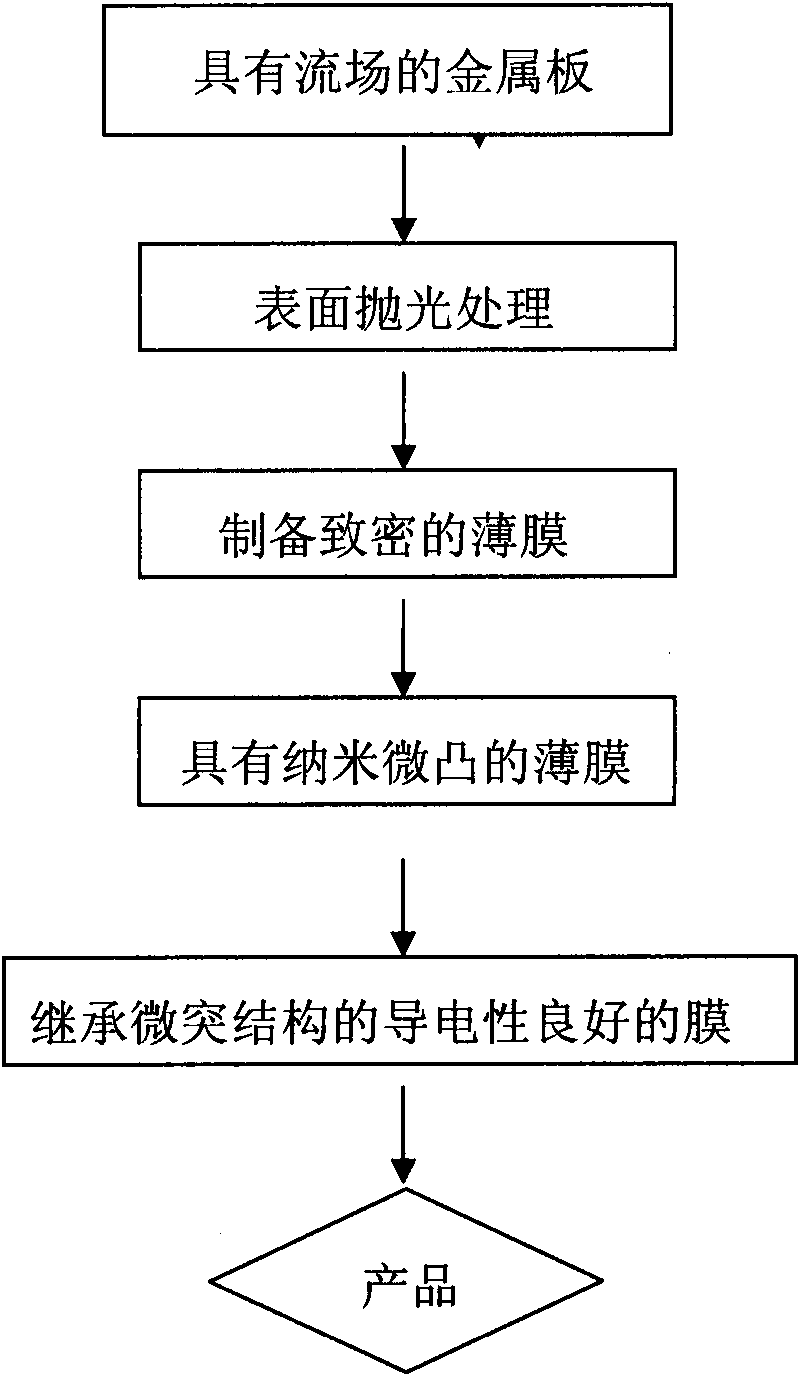

[0028] like figure 1 Shown, the preparation method of the metal-based fuel cell bipolar plate with hydrophobicity, it comprises the steps:

[0029]1) Take a 304 stainless steel plate with a flow field and perform surface polishing treatment to obtain a polished metal plate with a flow field.

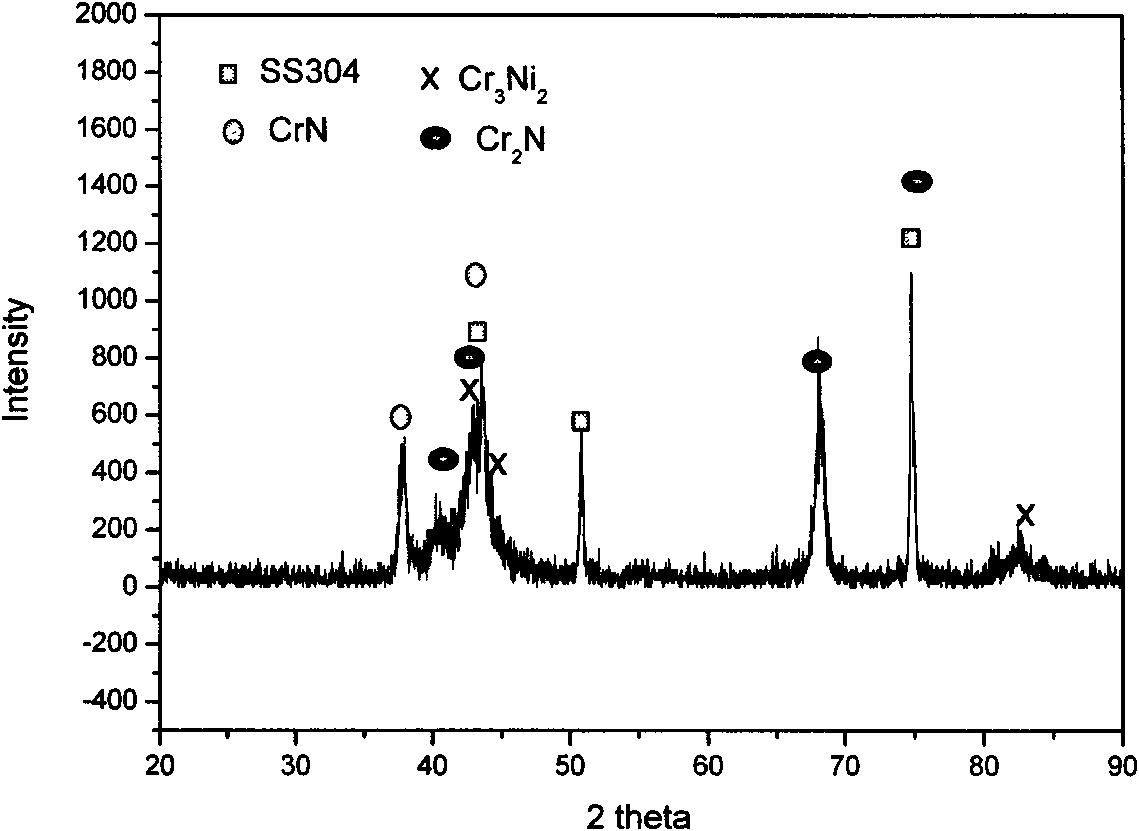

[0030] 2) Prepare a dense film: Put the polished metal plate with a flow field into a magnetron sputtering furnace for coating, select a Cr target, the temperature is 180 °C, and the vacuum degree is 2.0×10 -1 Pa, current 18A, voltage 300V, Ar / N 2 The gas volume flow ratio is 2:1, the coating time is 1.5 hours, a layer of dense CrN film is formed on the surface of the metal plate with a flow field, and a metal plate with a dense film is obtained.

[0031] 3) Prepare a thin film with nano-protrusions: the metal plate with a dense thin film obtained in step 2) is put into a magnetron sputtering furnace for coating, and the Cr 3 Ni 2 target, the temperature is 180°C, the vacuum degree i...

Embodiment 2

[0035] like figure 1 Shown, the preparation method of the metal-based fuel cell bipolar plate with hydrophobicity, it comprises the steps:

[0036] 1) Take a 304 stainless steel plate with a flow field and perform surface polishing treatment to obtain a polished metal plate with a flow field.

[0037] 2) Prepare a dense film: put the polished metal plate with a flow field into a magnetron sputtering furnace for coating, select a Cr target, the temperature is 220 °C, and the vacuum degree is 2.3×10 -1 Pa, current 16A, voltage 500V, Ar / N 2 The gas volume flow ratio is 3:1, the coating time is 1 hour, a layer of dense CrN film is formed on the surface of the metal plate with a flow field, and a metal plate with a dense film is obtained.

[0038] 3) Prepare a thin film with nano-protrusions: the metal plate with a dense thin film obtained in step 2) is put into a magnetron sputtering furnace for coating, and the Cr 3 Ni 2 target, the temperature is 220°C, the vacuum degree is ...

Embodiment 3

[0042] like figure 1 Shown, the preparation method of the metal-based fuel cell bipolar plate with hydrophobicity, it comprises the steps:

[0043] 1) Take a 304 stainless steel plate with a flow field and perform surface polishing treatment to obtain a polished metal plate with a flow field.

[0044] 2) Prepare a dense film: put the polished metal plate with a flow field into a magnetron sputtering furnace for coating, select a Cr target, the temperature is 220°C, and the vacuum degree is 2.1×10 -1 Pa, current 17A, voltage 400V, Ar / N 2 The gas volume flow ratio is 2:1, the coating time is 2 hours, a layer of dense CrN film is formed on the surface of the metal plate with a flow field, and a metal plate with a dense film is obtained.

[0045] 3) Prepare a thin film with nano-protrusions: the metal plate with a dense thin film obtained in step 2) is put into a magnetron sputtering furnace for coating, and the Cr 3 Ni 2 target, the temperature is 220°C, the vacuum degree is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact resistance | aaaaa | aaaaa |

| Contact resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com