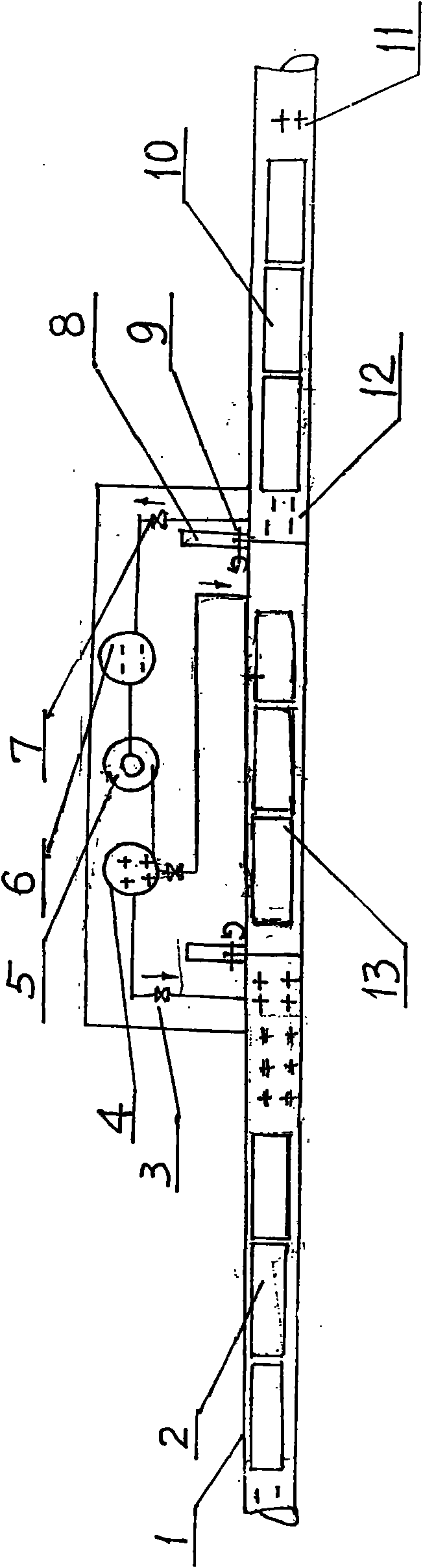

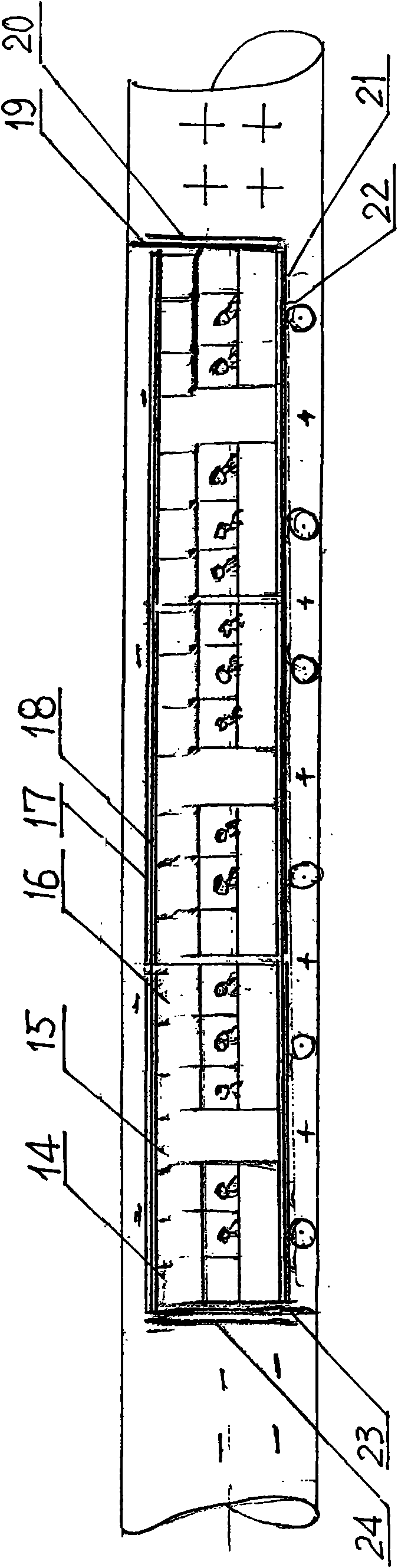

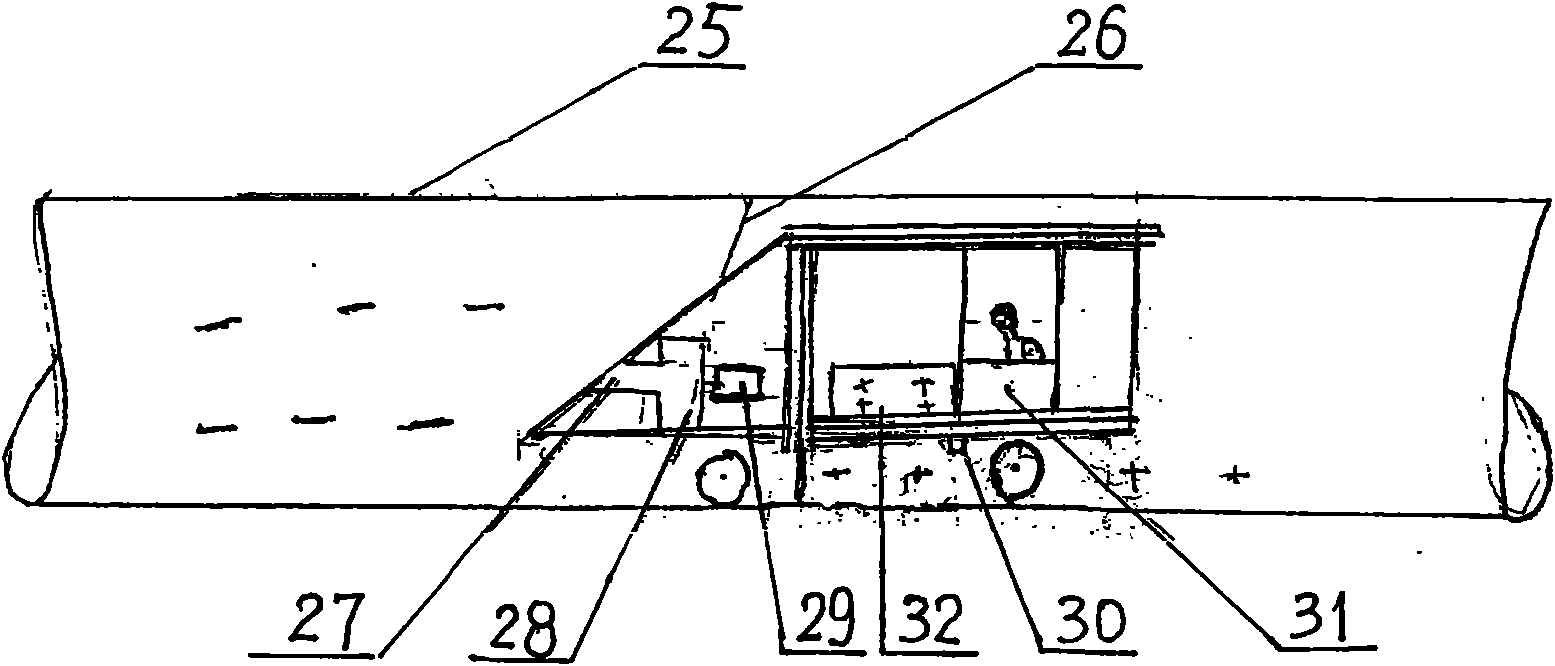

Energy-saving and emission-reducing pipe or channel ultra-high speed wing-in-surface effect air cushion vehicle transportation system

A technology for energy saving, emission reduction, and transportation system, applied in tunnel systems, roads, tracks, etc., can solve problems such as waste, exhaust gas pollution, low thermal efficiency, etc., and achieve low operating costs, high energy utilization, and large transportation volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0055] Example 1: Assume that the inner diameter of the pipeline is 3m, the passable outer diameter is about 2.8m, and the air float vehicle is set to be 2.4m wide by the bottom plate plus the wing, 2m wide by the roof plate and the wing, and 6m long, and the weight of the car is 3T, and it can carry 30 people Passengers plus luggage are about 3T, and the total weight of the car is 6T. How much pressure difference is needed to make the car float off the wheel rail?

[0056] Solution: 1 atmosphere = 1kg / cm 2

[0057] The average pressure area of the bottom and roof is 13.2m 2

[0058] ∵x=0.046

[0059] Answer: Only need 0.046 atmospheric pressure difference to float

example 2

[0060] Example 2: For a channel air float vehicle, the effective pressure-bearing cross-load surface width of the channel and channel cover is 1m, the vehicle length is 12.5m, the vehicle's self-weight is 15T, and the load is 60T. How much channel pressure is required to float the vehicle?

[0061] untie: ∴ x = 0.6 atmosphere

[0062] Answer: It takes 0.6 atmospheric pressure to float the car.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com