Method for preparing threonine zinc

A technology of threonine zinc and threonine, which is applied in the field of preparation of amino acid chelates, can solve the problems of long synthesis reaction time, reduced product purity, and low reaction efficiency, and achieves shortened production cycle, easy control of impurities, The effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

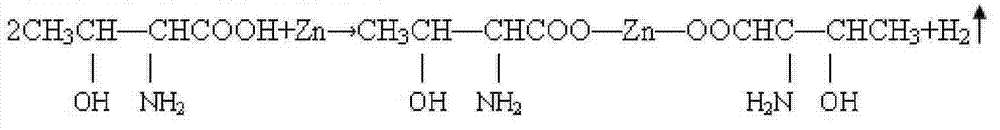

Image

Examples

Embodiment 1

[0019] Zinc threonine is prepared through the following reaction steps: first take 24.31g threonine, put it into a reaction kettle filled with 150ml of reaction water and stir fully, then put 6.5g of zinc powder into it, and adjust the pH value of the reaction mixture at 65°C 6.8, react for 2 hours under normal pressure, then extract the reaction product with ethanol for 30 minutes, the volume ratio of ethanol and reaction product is 9:1, dry the extracted precipitate in a flash at 120°C, and grind it to obtain Zinc threonine finished product.

Embodiment 2

[0021] Zinc threonine was prepared through the following reaction steps: First, take 60g of threonine, put it into a reaction kettle filled with 400ml of reaction water and stir thoroughly, then put in 8.0g of zinc powder, and adjust the pH value of the reaction mixture to 6.7 at a temperature of 80°C , reacted for 2.5 hours under normal pressure, then extracted the reaction product with ethanol for 20 minutes, the volume ratio of ethanol to the reaction product was 6:1, flashed and dried the extracted precipitate at a temperature of 100 ° C, and prepared after crushing Get the zinc threonine finished product.

Embodiment 3

[0023] Zinc threonine is prepared by the following reaction steps: first take 44g threonine, put it into a reaction kettle filled with 250ml of reaction water and stir thoroughly, then put in 8.0g of zinc powder, and adjust the pH value of the reaction mixture to 6.4 at a temperature of 50°C , reacted for 3h under normal pressure, and then sent the reaction product to the concentration tank, at 0.25kgf / cm 2 Vacuum concentration is carried out under a certain degree of vacuum, the concentration temperature is 85°C, and the concentration time is 80 minutes. After the product is viscous, the concentrate is fed into the tray, flashed and dried at 110°C, and crushed to prepare Zinc threonine finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com