System and method for reclaiming hexanolactam from rearrangement mixture

A caprolactam and mixture technology, applied in the field of caprolactam recovery, can solve the problems of incomplete reaction, abnormal operation and loss of continuous extraction equipment, and achieve the effect of reducing raw material loss, maintaining continuous operation and improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The characteristics and functions of the present invention will be further illustrated by specific examples below, but the present invention is not limited thereto.

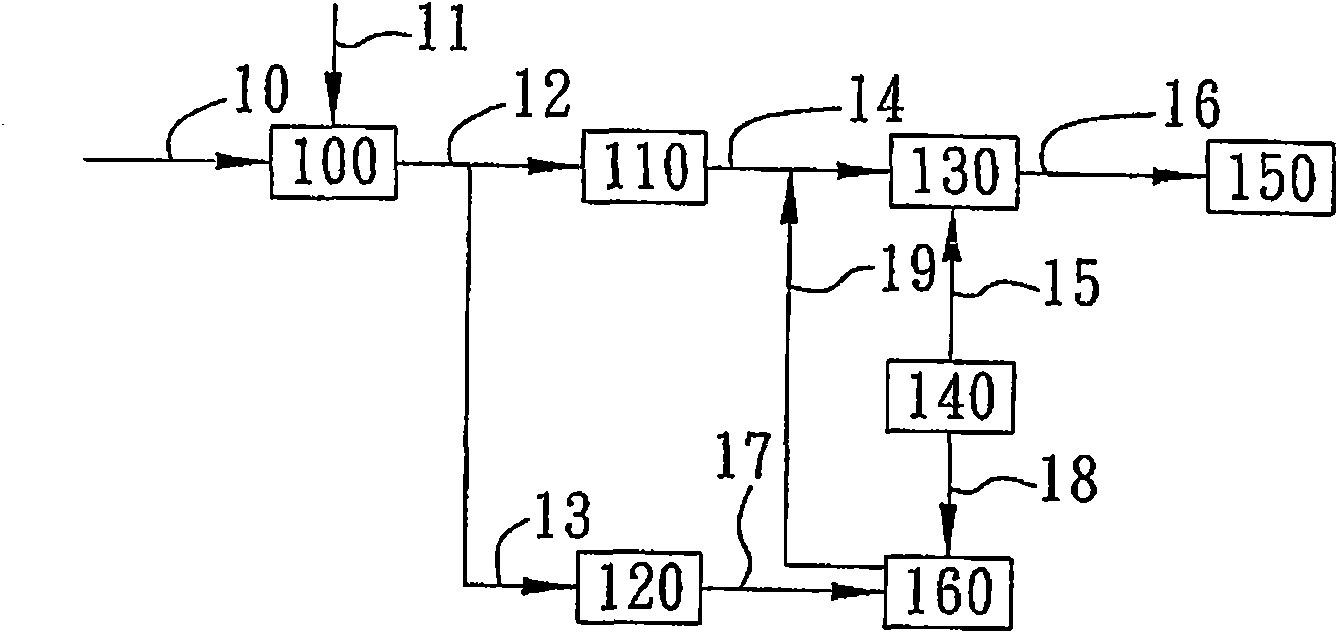

[0030] figure 1 A first embodiment of the present invention system for the recovery of caprolactam from a rearranged mixture of cyclohexanone oxime and sulfuric acid is shown. As shown in the figure, the rearrangement mixture of cyclohexanone oxime and sulfuric acid and alkali, such as ammonia water, are respectively sent to the neutralization unit 100 through the pipeline 10 and the pipeline 11 for neutralization reaction to form a crude amide solution. When the quality of the reactants is not good or the reaction is not complete at the initial stage of operation, the organic impurity content (for example, ketones and alcohols) in the crude amide solution formed by the reaction is higher than the standard value, such as higher than 500ppm, or higher than 200ppm, or higher than the standard value. When i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com