Preparation method of a non-hydrated proton exchange membrane for reducing methanol permeability

A proton exchange membrane, non-hydration technology, used in fuel cell parts, solid electrolyte fuel cells, structural parts, etc., can solve problems such as reducing methanol permeation, and achieve the effect of reducing methanol permeation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

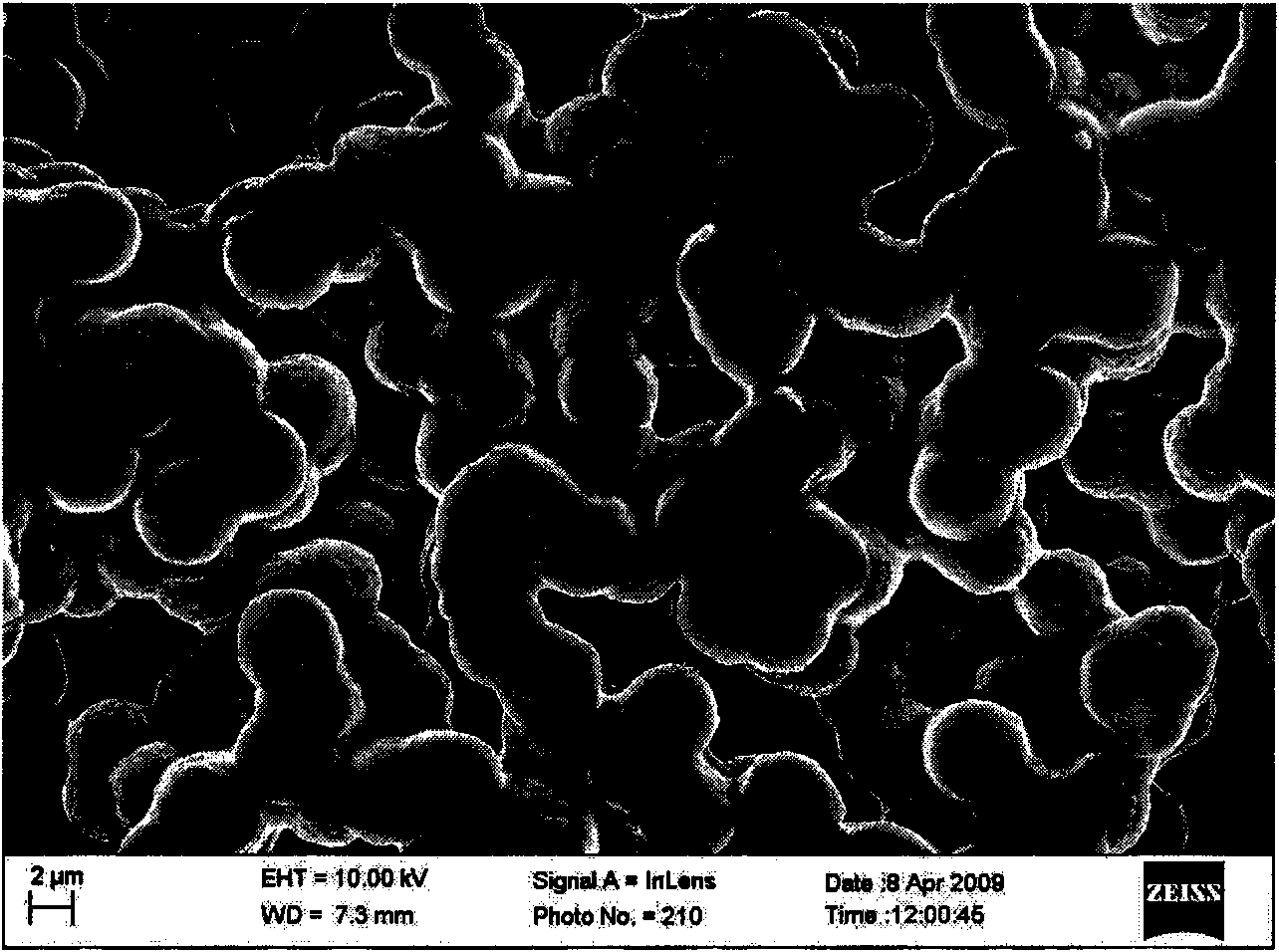

Embodiment 1

[0020] 1. Mix P(VdF-HFP) and solvent (Ac+NMP) uniformly to obtain a colorless and transparent solution of P(VdF-HFP) with a mass percentage of 11%, wherein the percentage of NMP is 3.1%.

[0021] 2. Heat the colorless solution in step 1 to 55° C., stir and reflux at constant temperature for 6 hours to obtain a colorless transparent viscous solution.

[0022] 3. Slowly add the non-hydrated proton electrolyte ionic liquid 1-ethyl-3-methylimidazolium tetrafluoroborate into the solution obtained in step 2, so that the percentage of the ionic liquid is 4%, and the system is ultrasonically Treat for 10 min to mix well.

[0023] 4. Stir the colorless and transparent solution obtained in step 3 at constant temperature for 2.5 hours, and then lower the temperature to 25°C to obtain a viscous, colorless and homogeneous casting solution.

[0024] 5. Cast the viscous solution obtained in step 4 into a Petri dish, and after the solvent evaporates, dry the obtained polymer film in a vacuum...

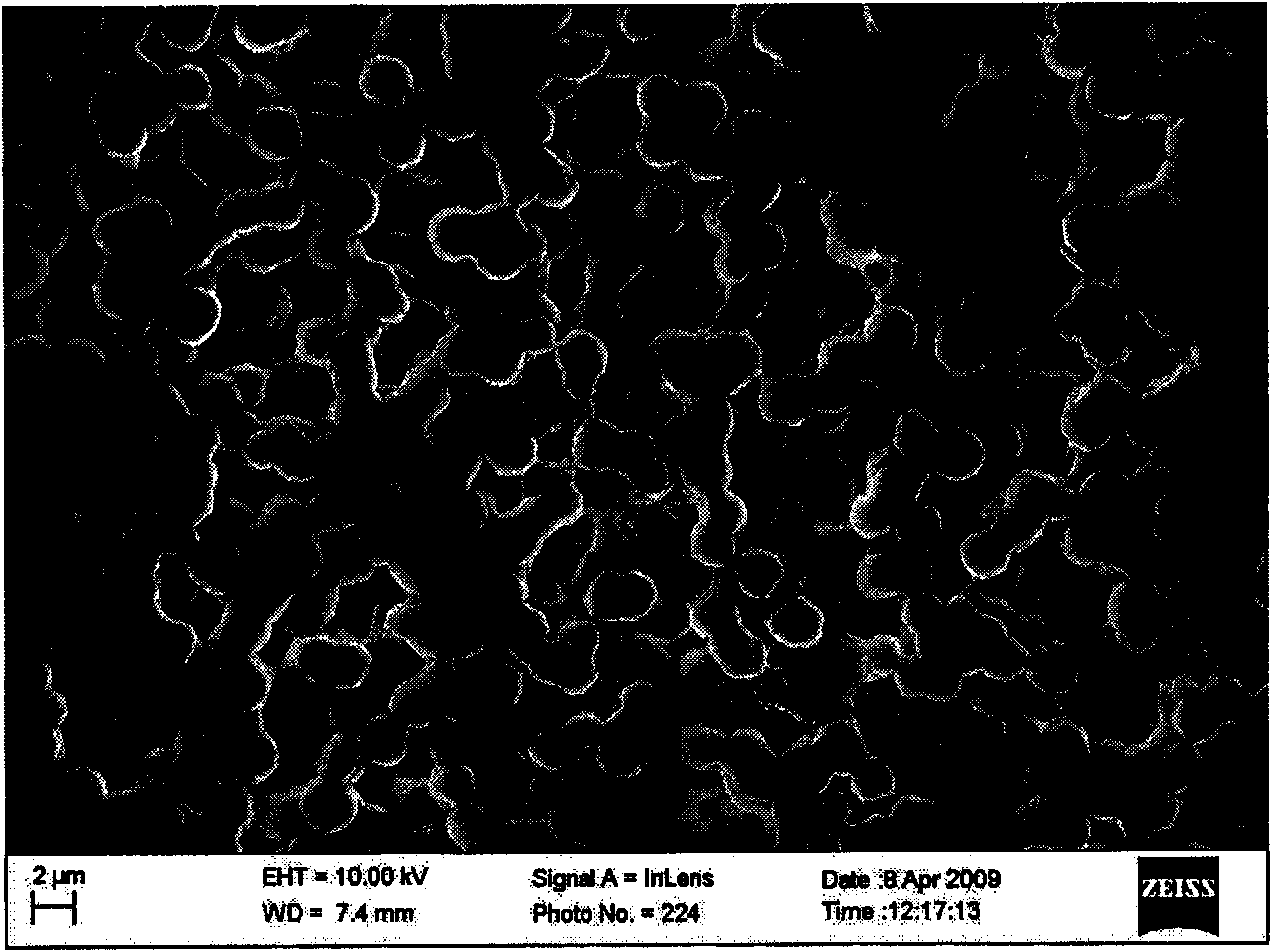

Embodiment 2

[0027] 1. Mix P(VdF-HFP) and solvent (Ac+NMP) uniformly to obtain a colorless and transparent solution of P(VdF-HFP) with a mass percentage of 9%, wherein the percentage of NMP is 4%.

[0028] 2. Heat the colorless solution in step 1 to 60° C., stir and reflux at constant temperature for 4 hours to obtain a colorless transparent viscous solution.

[0029] 3. Slowly add the non-hydrated proton electrolyte ionic liquid 1-ethyl-3-methylimidazolium tetrafluoroborate into the solution obtained in step 2, so that the percentage of the ionic liquid is 7%, and the system is ultrasonically Treat for 10 min to mix well.

[0030] 4. Stir the colorless and transparent solution obtained in step 3 at constant temperature for 3 hours, and then lower the temperature to 25° C. to obtain a viscous colorless homogeneous casting solution.

[0031] 5. Cast the viscous solution obtained in step 4 into a Petri dish. After the solvent evaporates, dry the obtained polymer film in a vacuum oven at 70°...

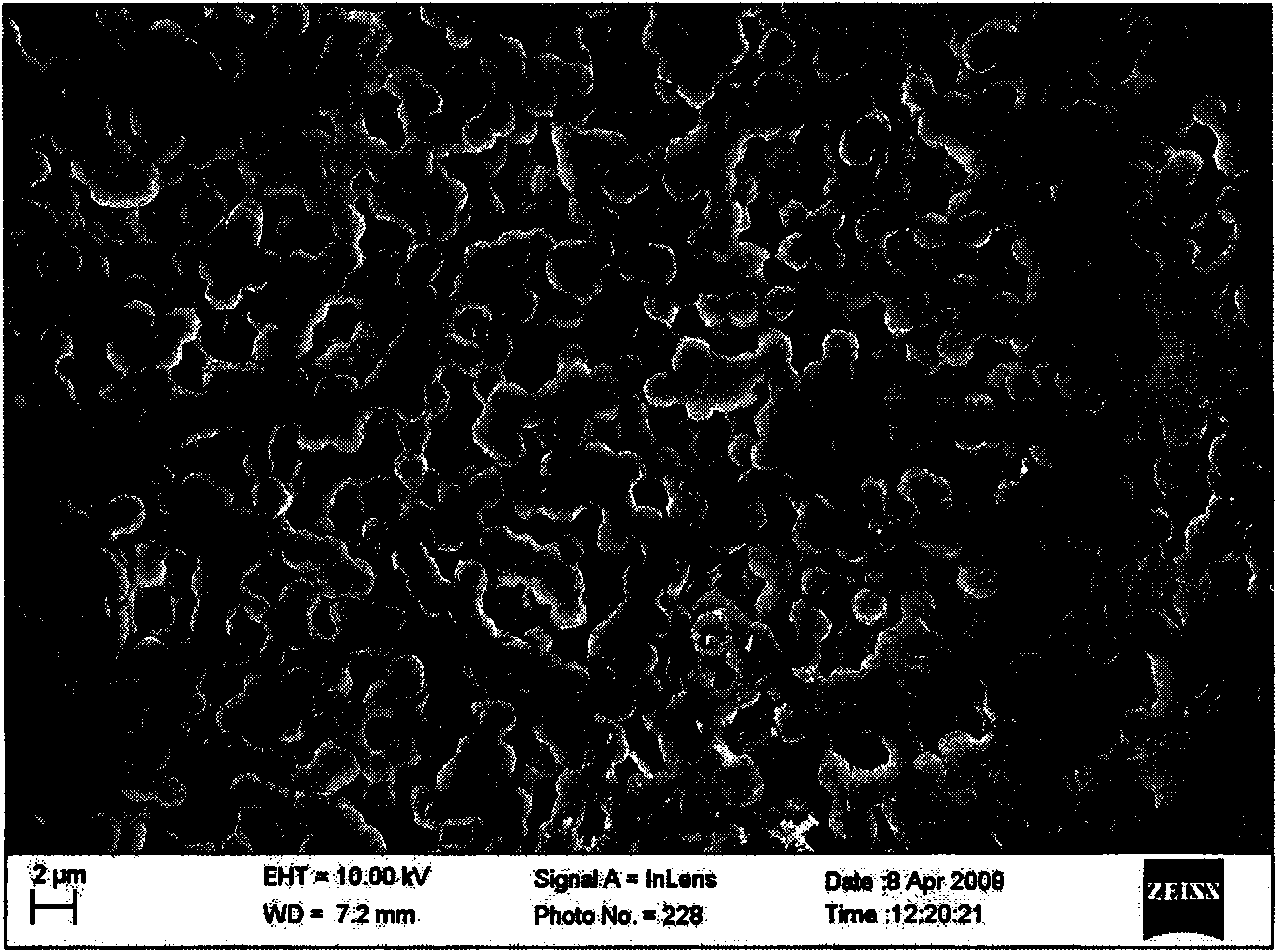

Embodiment 3

[0034] 1. Mix P(VdF-HFP) and solvent (Ac+NMP) uniformly to obtain a colorless and transparent solution of P(VdF-HFP) with a mass percentage of 6.25%, wherein the percentage of NMP is 6.25%.

[0035] 2. Heat the colorless solution in step 1 to 50° C., stir and reflux at a constant temperature for 2 hours to obtain a colorless transparent viscous solution.

[0036] 3. Slowly add the non-hydrated proton electrolyte ionic liquid 1-ethyl-3-methylimidazolium tetrafluoroborate into the solution obtained in step 2, so that the percentage of the ionic liquid is 11%, and the system is ultrasonically Treat for 10 min to mix well.

[0037] 4. Stir the colorless and transparent solution obtained in step 3 at constant temperature for 3 hours, and then lower the temperature to 25° C. to obtain a viscous colorless homogeneous casting solution.

[0038] 5. Cast the viscous solution obtained in step 4 into a Petri dish. After the solvent evaporates, dry the obtained polymer film in a vacuum ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com