Flow field sensor and manufacturing method thereof

A manufacturing method and sensor technology, applied in the field of flow field sensors, can solve the problems of limited dynamic performance of sensors, low integration of measurement circuits, and difficulty in surface installation of objects, and achieve the effects of light weight, easy installation, and small heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

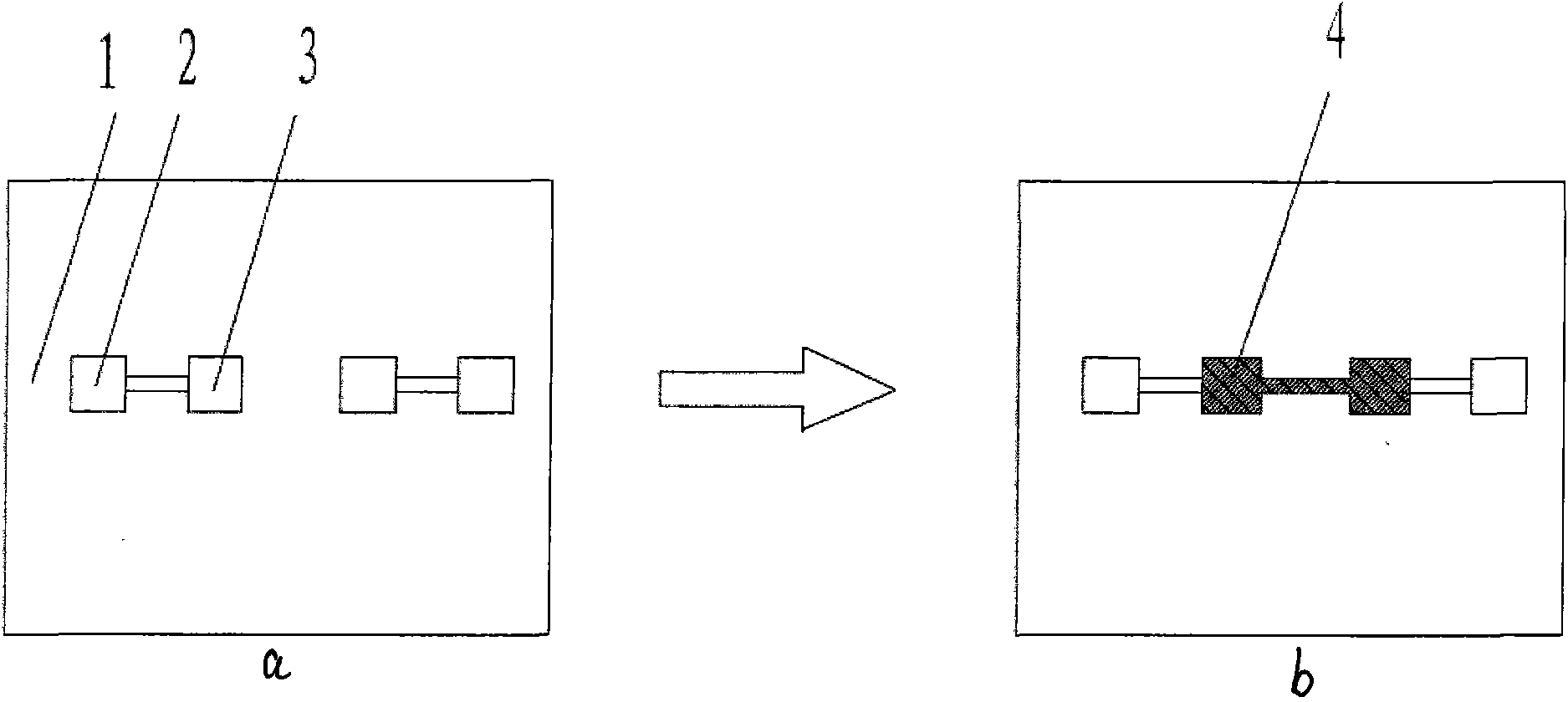

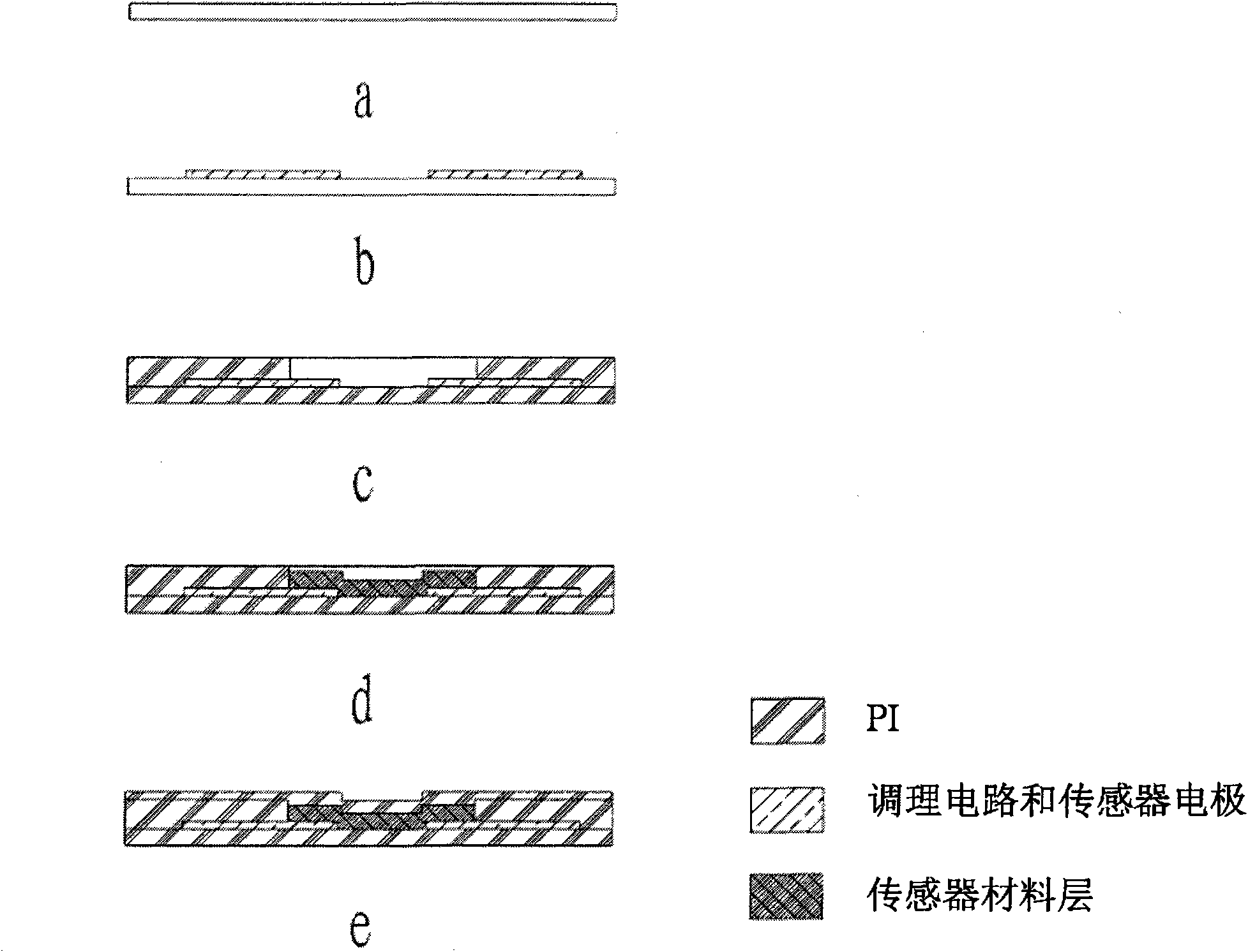

[0034] The flow field sensor of the present invention includes a conditioning circuit manufactured on a circuit board through standard circuit board processing techniques and a sensitive material layer electrically connected to the conditioning circuit.

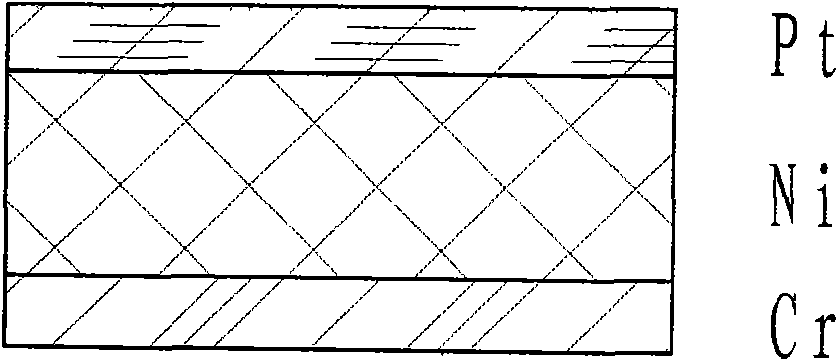

[0035] The sensitive material generally can be selected from nickel or platinum or other suitable materials, wherein the sensitive material layer can be a single-layer sensitive material, or a multi-layer composite structure, that is, composed of multi-layer sensitive materials, for the composite structure, The thickness ratio between the layers of sensitive materials can be determined according to actual needs. The sensitive material layer of the composite structure is well known to those skilled in the art. It usually uses platinum and other materials with good stability and strong oxidation resistance as the outermost layer. The advantage is that it solves the problem of easy oxidation of sensitive materials such as nickel,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com