Yb3+ doped oxyfluoride transparent glass-ceramic material and preparation method thereof

A technology of glass-ceramics and oxyfluoride, which is applied in the field of glass-ceramics materials and their preparation, can solve the problems of high raw material purity requirements, harsh preparation conditions, difficult material performance tailoring, etc., and achieve excellent physical properties and chemical stability, The preparation method is simple and the production cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

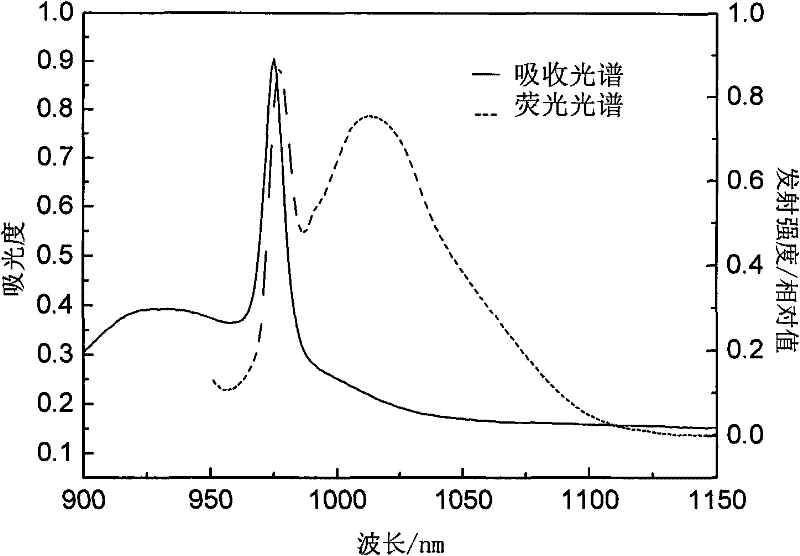

Examples

Embodiment 1、2、3

[0016] Table 1 shows the glass chemical composition of 7 specific examples.

[0017] Embodiment 1,2,3 is taken by the chemical composition in table 1

[0018] Specific steps are as follows:

[0019] Step 1: Melting of glass, according to the chemical composition in Table 1, convert it into the weight of corresponding raw materials. Accurately weigh the weight of the corresponding raw materials for each composition, and make batches by ball milling and mixing evenly. Put the batch material into a quartz crucible or a platinum crucible, raise the temperature to 1400°C at a rate of 5-10°C / min in a silicon-molybdenum rod resistance furnace, and keep it warm for 1.5h to prepare a uniform glass solution. Quickly pour the glass melt into a stainless steel mold that has been preheated at 560°C, and quickly move it to the muffle furnace that has been heated to the preheating temperature, anneal at 530°C for 1.5h, and then close the muffle furnace The furnace is cooled to room temper...

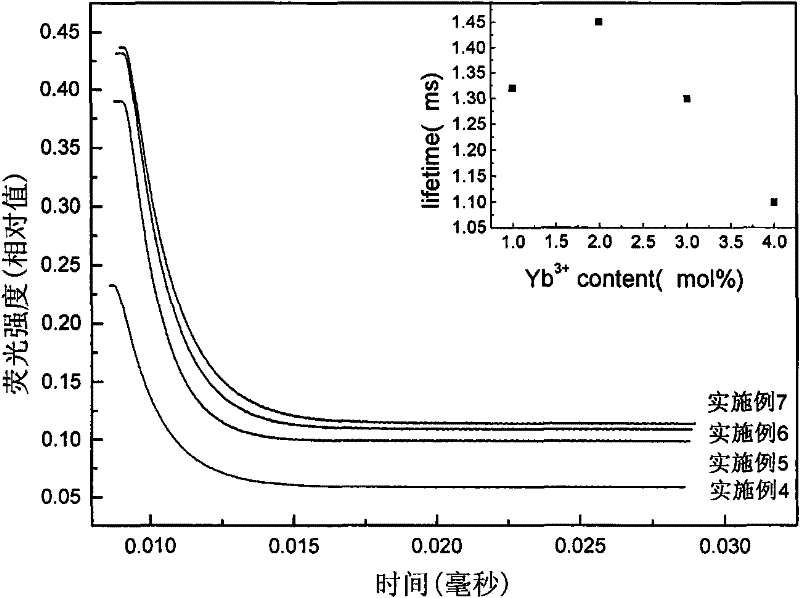

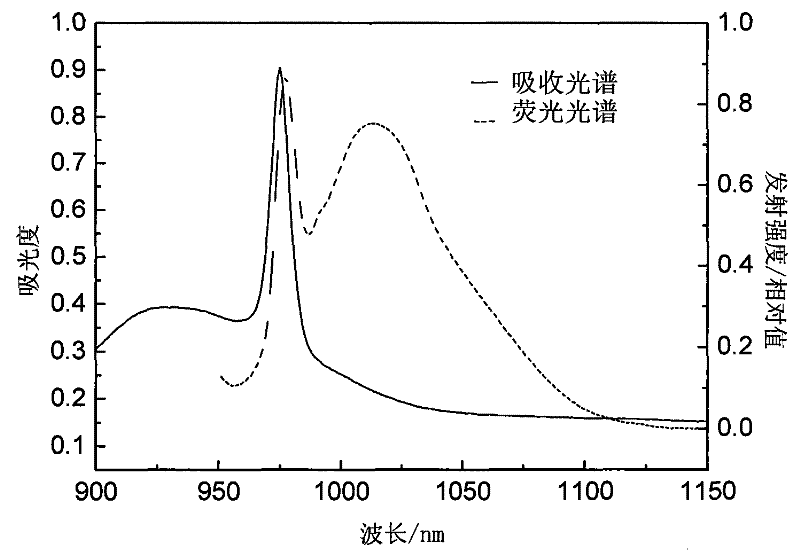

Embodiment 4、5、6、7

[0022] Step 1: Melting of glass, according to the chemical composition in Table 1, convert it into the weight of corresponding raw materials. Accurately weigh the weight of the corresponding raw materials for each composition, and make batches by ball milling and mixing evenly. Put the batch material into a quartz crucible or a platinum crucible, raise the temperature to 1420°C in a silicon-molybdenum rod resistance furnace at a heating rate of 5-10°C / min, and keep it for 1.5h to prepare a uniform glass solution. Quickly pour the glass melt into a stainless steel mold that has been preheated at 560°C, and quickly move it to the muffle furnace that has been heated to the preheating temperature, anneal at 530°C for 1.5h, and then close the muffle furnace The furnace is cooled to room temperature to obtain a colorless, transparent, uniform, and bubble-free bulk base glass.

[0023] Step 2: According to the characteristic temperature value obtained by the DSC test of the basic gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption cross section | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com