Method and device for preventing olefine polymerization reactor of gas phase fluidized bed from caking

A gas-phase fluidized bed, olefin polymerization technology, applied in the field of gas-phase fluidized bed olefin polymerization reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

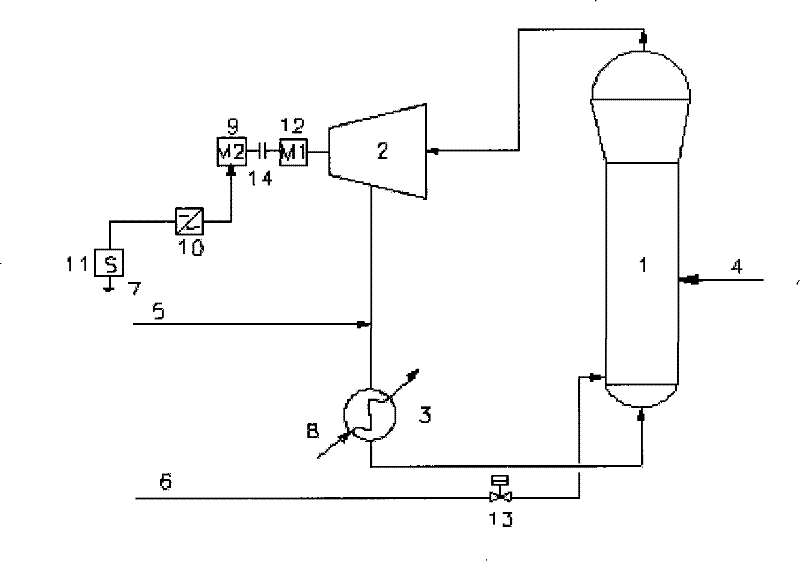

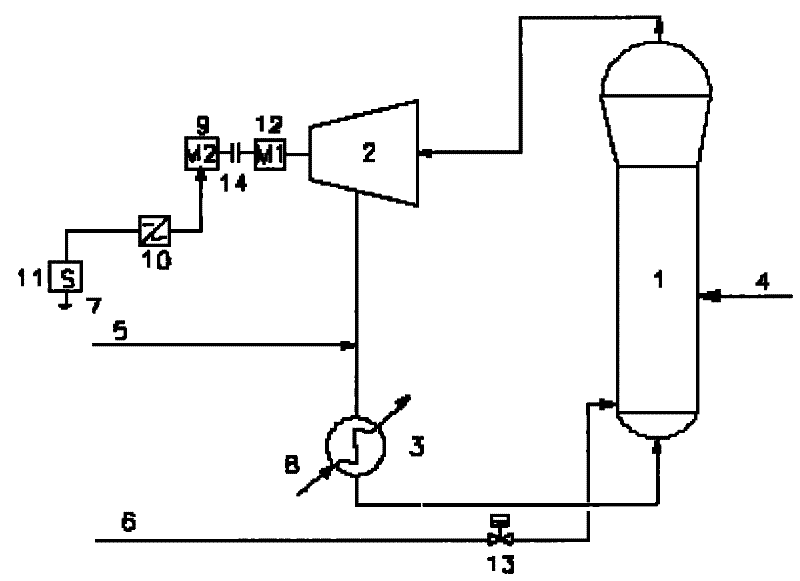

[0023] The polymerization reaction system adopts a conventional gas-phase fluidized bed olefin polymerization reaction system (such as the gas-phase fluidized bed olefin polymerization reaction system disclosed in US Patent No. 5,270,408 in its embodiment 1), which mainly includes a polymerization reactor 1, a circulating gas compressor 2. Compressor main motor 12, circulating gas cooler 3 and connecting pipes, etc. Polymerization monomer 5 (one or more olefin monomers) and catalyst 4 with transition metal as the active center are added to polymerization reactor 1 for gas phase polymerization to generate polymer, and a certain amount of circulating gas (containing olefin monomer , hydrogen, diluent and other substances) come out from the polymerization reactor 1, and are transported through the circulating gas compressor 2 driven by the compressor main motor 12, and after being cooled by the circulating gas cooler 3 (which exchanges heat through the coolant 8), Return to polym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com