Method for deoxidizing molten steel

A technology of molten steel and final deoxidation, which is applied in the refining production process outside the furnace and the deoxidation process of ultra-low carbon steel treated in a vacuum furnace. The effect of producing, improving surface quality and reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

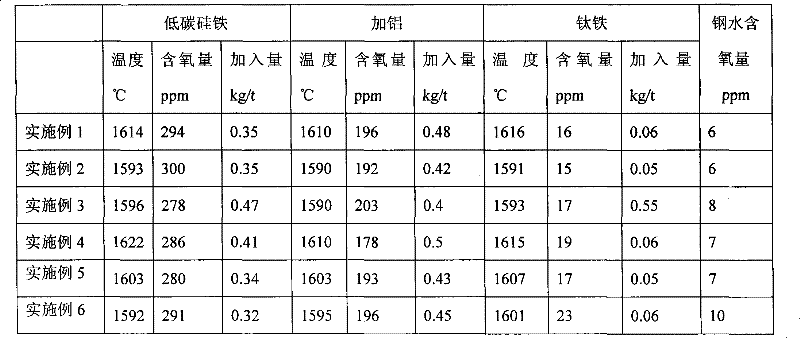

Examples

Embodiment Construction

[0027] The main feature of the present invention is that after the molten steel is decarburized and degassed in the RH device, it is deoxidized by a three-step method. First, low-carbon ferrosilicon is added for deoxidation to ensure that the silicon content does not exceed the composition requirements of the steel made, and then Aluminum is then added for deoxidation to ensure that the free oxygen content in the molten steel is not greater than 0.0020%, and finally ferro-titanium is added for final deoxidation.

[0028] Specific steps are as follows,

[0029] 1) When the molten steel temperature is 1590-1620°C, first add low-carbon ferrosilicon (wherein Si is 75%-78%, C≤0.1%, and the balance is Fe), and the addition amount is 0.4-0.5kg / t; 1 to 3 minutes, control the oxygen content ≤0.015%;

[0030] 2) Measure the oxygen content of molten steel, add 0.4-0.5kg / t of aluminum according to the oxygen content, circulate for 2-4 minutes, and control the oxygen content at about 0.00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com