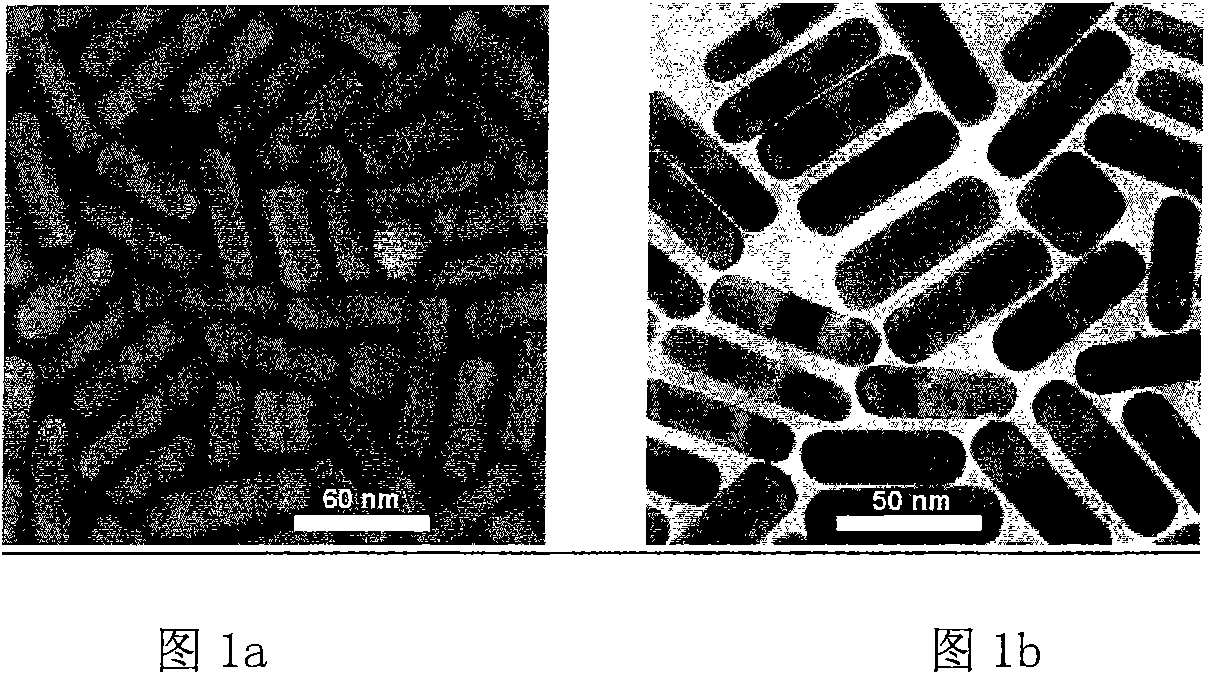

Island-shaped porous tri-metal nano rod with gold core/silver-platinum alloy shell structure and method for preparing same

A technology of gold nanorods and platinum alloys, applied in the field of metal nanorods and its preparation, can solve problems that have not been seen, and achieve the effects of strong anti-poisoning ability, simple operation, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] First prepare the following solutions:

[0043] (1) 0.1M cetyltrimethylammonium bromide (C 19 h 42 N + Br - , hereinafter referred to as CTAB) aqueous solution:

[0044] Weigh 3.64g of cetyltrimethylammonium bromide (analytical grade) and dissolve in 100mL of deionized water; before use, it should be placed in a constant temperature water bath at 30°C to dissolve completely to obtain 0.1M cetyltrimethylammonium bromide ammonium bromide (C 19 h 42 N + Br - , hereinafter referred to as CTAB) aqueous solution;

[0045] (2) 0.1M ascorbic acid (AA) aqueous solution:

[0046] Weigh 0.176g of ascorbic acid (analytical pure) and dissolve it in 10mL of deionized water to obtain a 0.1M ascorbic acid (AA) aqueous solution (the solution can be temporarily prepared before use);

[0047] (3) 10mM tetrachloroauric acid (HAuCl 4 ·3H 2 O) Aqueous solution:

[0048] Weigh 0.393g tetrachloroauric acid (analytical pure, domestic) and dissolve it in 100mL deionized water to pre...

Embodiment 2

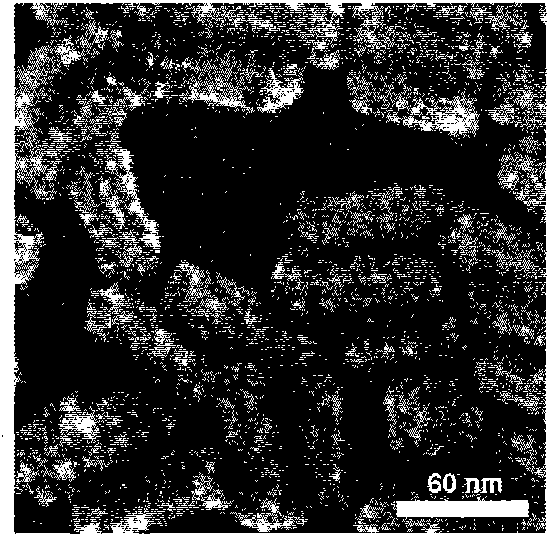

[0072] Take 2mL of the platinum-coated gold core / platinum shell structure nanorod solution obtained in step 4 of Example 1 and put it into a test tube, and add 40uL 2mM potassium tetrachloroplatinite aqueous solution and 0.8uL 10mM nitric acid successively to the solution Silver solution, mix well and add 8uL 0.1M ascorbic acid aqueous solution; mix well and put it in a constant temperature water bath at 30°C. After 30 minutes, the solution turns from gray red to dark gray black, which shows the gold core / platinum silver alloy shell structure three Formation of metal nanorods; add 1mL 0.1M hexadecyltrimethylammonium bromide aqueous solution after 5 to 6 hours to stabilize the three metal nanorods with gold core / platinum silver alloy shell structure; Centrifuge at a speed of 5 minutes per minute; remove the supernatant, dilute the precipitate with deionized water to the original volume, ultrasonically disperse, and then centrifuge under the same conditions; Metal nanorods are s...

Embodiment 3

[0075] In this example, except that the volume of silver nitrate is 2.64 μL, the remaining steps are the same as in Example 2, and the obtained image of the island-shaped porous trimetallic nanorod with gold core / silver-platinum alloy shell structure is as follows: Figure 7b shown;

[0076] The weight ratio of silver nitrate, potassium tetrachloroplatinite and pure gold nanorods in the mixed solution in this example is 0.3:1:5.9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com