Organic fertilizer and preparation process thereof

A technology of organic fertilizers and raw materials, applied in the direction of organic fertilizers, inorganic fertilizers, fertilizer mixtures, etc., can solve problems such as collection difficulties, and achieve the effects of good quality, high utilization rate, and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Formula: plant ash 45%, ash 10%, humic acid 40%, magnesium oxide 5%.

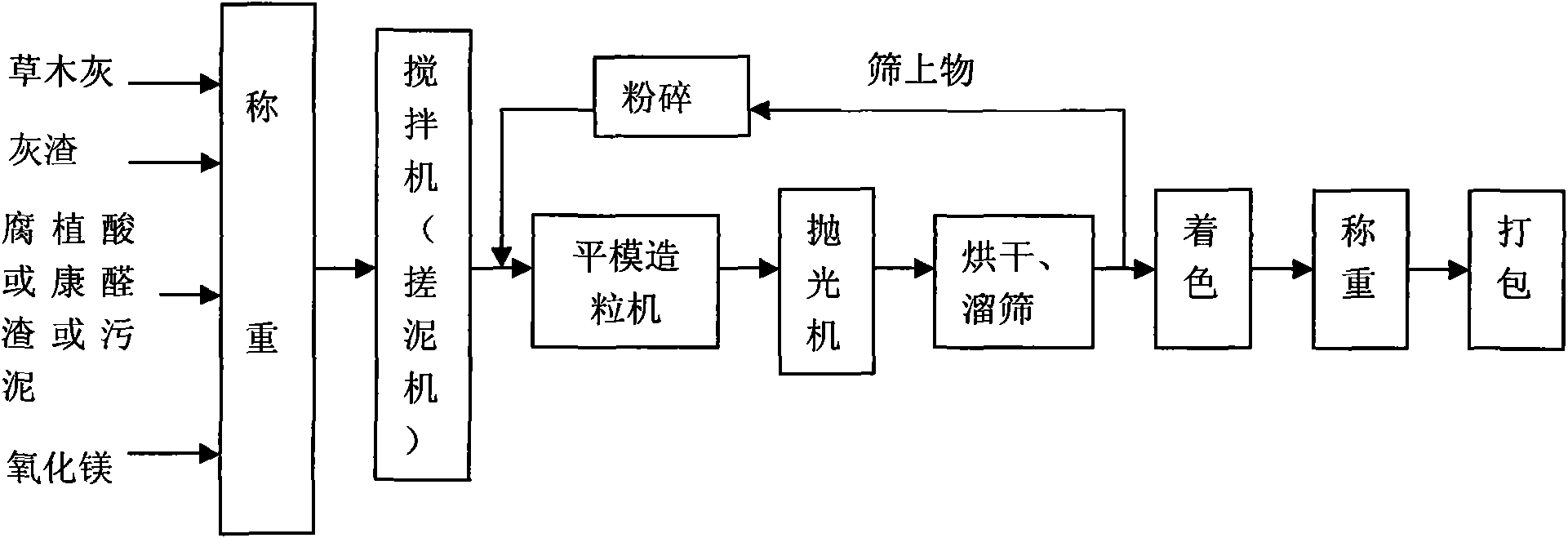

[0031] Preparation:

[0032] (1) Weigh each raw material according to the above parts by weight.

[0033] (2) After fully stirring the prepared raw materials, the water content is 20-30%, and then enter the flat die granulator to generate columnar particles, and then enter the polishing and shaping machine for shaping and polishing, and use the elevator to send to the oven Drying in a dry tunnel, sliding down naturally and grading, then coloring, weighing, and packing, is the finished product.

Embodiment 2

[0035] Formula: plant ash 60%, ash residue 9%, furfural residue 30%, magnesium oxide 1%.

[0036] Preparation method: except that the proportioning is the above-mentioned proportioning, all the other are the same as in Example 1.

Embodiment 3

[0038] Formula: plant ash 60%, ash 5%, sludge 30%, magnesium oxide 5%.

[0039] Preparation method: except that the proportioning is the above-mentioned proportioning, all the other are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com