Method for synthesizing beta-hydroxymethyl butyrate

A technology of methyl hydroxybutyrate and methyl formate, which is applied in the field of synthesis of methyl β-hydroxybutyrate, can solve the problems of difficult storage and use of catalysts, and achieve cheap raw materials and catalysts, small scale, and mild reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

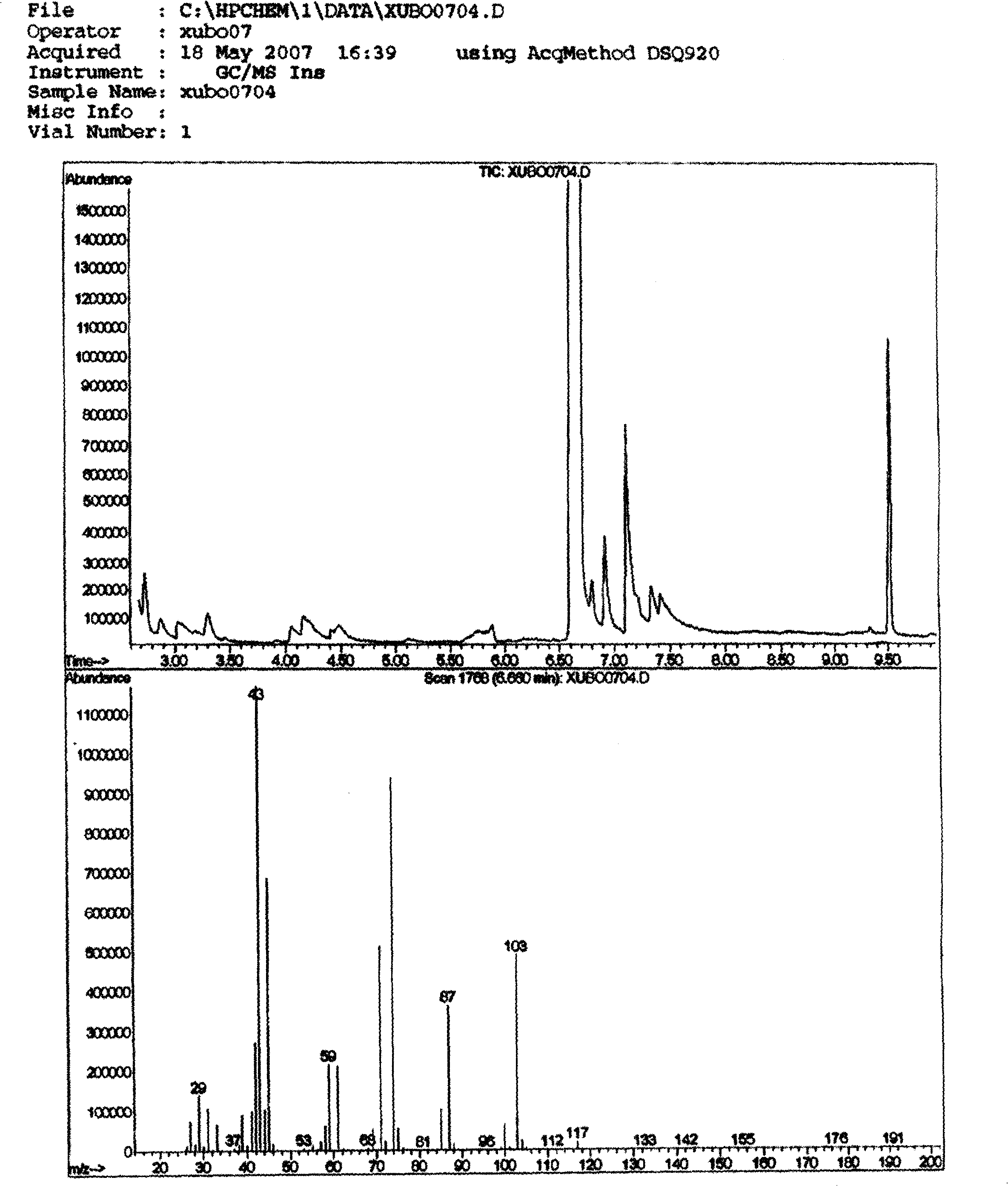

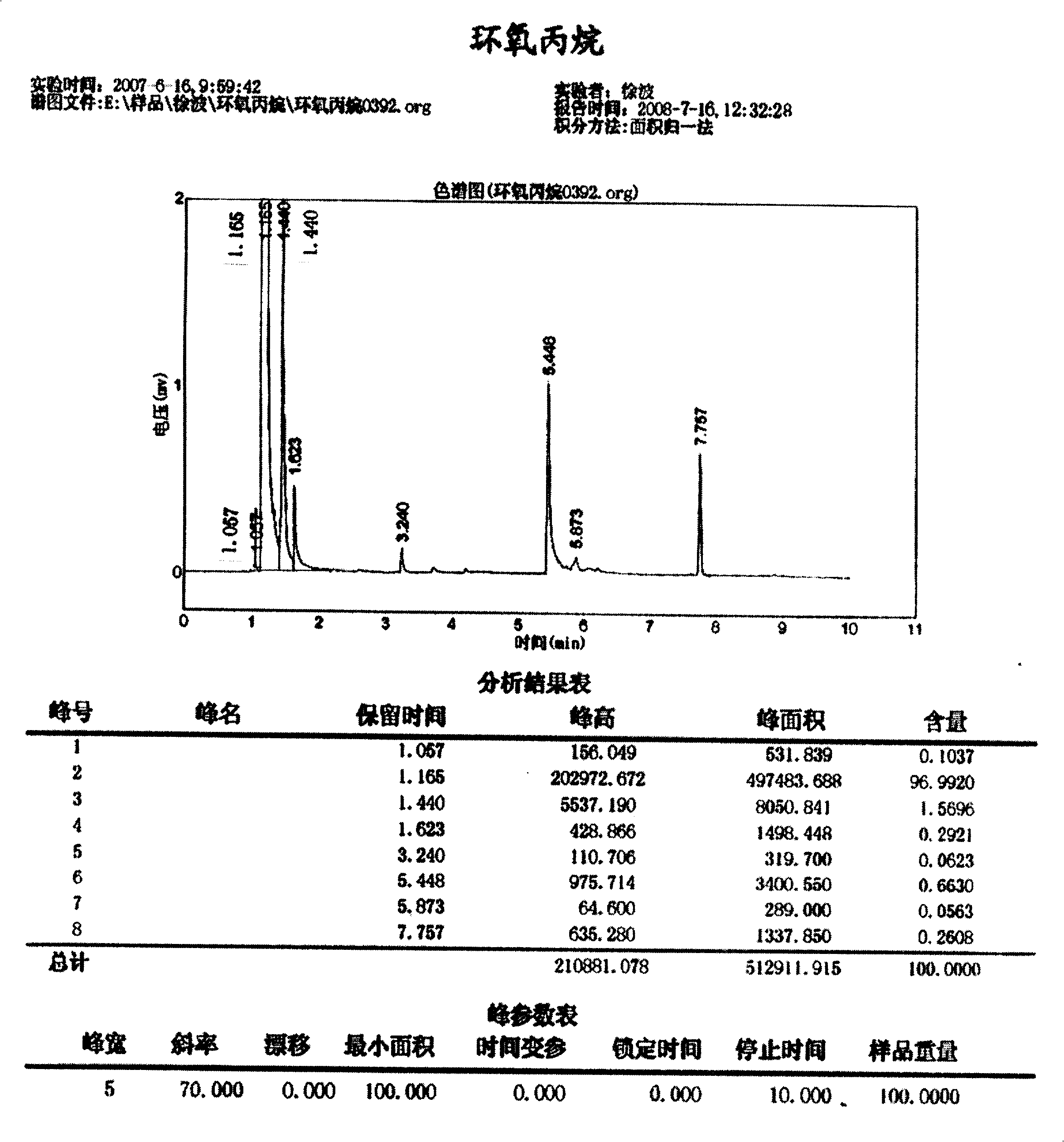

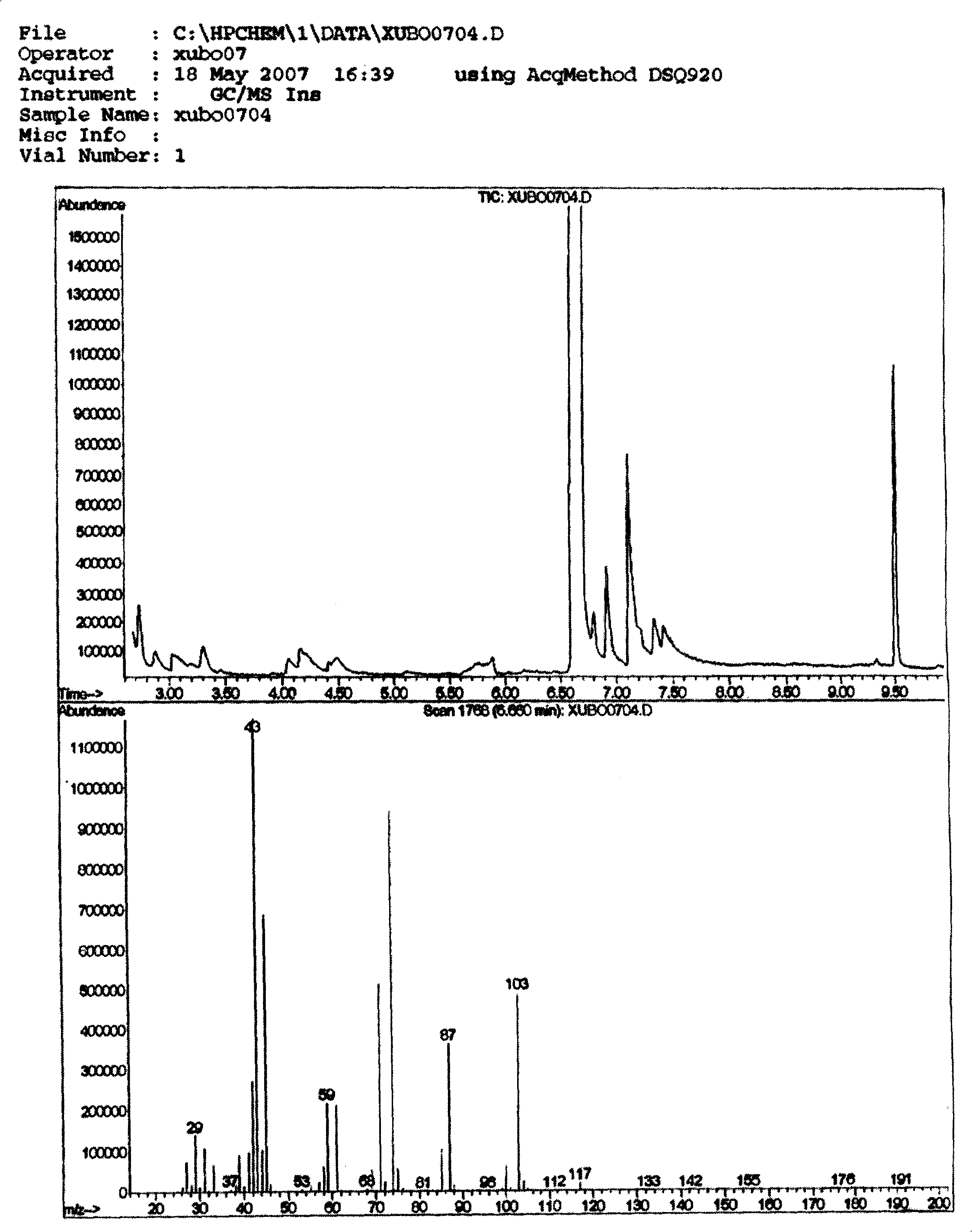

[0030] Propylene oxide (analytically pure) was mixed with methanol to prepare a methanol solution with a concentration of 250mmol / L. Mix the catalyst cobalt acetate, cadmium iodide and methanol to prepare a methanol solution with a concentration of 8mmol / L, wherein the total concentration of cobalt acetate and cadmium iodide is 8mmol / L, and the molar ratio of cobalt acetate and cadmium iodide is 1:9 . The above methanol solution of the catalyst was mixed with the above methanol solution of propylene oxide. Add sodium acetate in the above mixed solution, its concentration in the mixed solution is 300mmol / L. A 100W high-pressure mercury lamp is placed inside a quartz photoreactor with a hollow interlayer, and circulating water is passed into the interlayer, and the entire reactor is placed in a water tank filled with water to cool the light source. Add 4ml of methanol solution containing 250mmol / L propylene oxide, 8mmol / L catalyst cobalt acetate and cadmium iodide, and 300mmol...

example 2

[0032] Propylene oxide (analytical pure) was mixed with methanol to prepare a methanol solution with a concentration of 1000mmol / L. Mix the catalyst cobalt acetate, cadmium iodide and methanol to prepare a methanol solution with a concentration of 16mmol / L, wherein the total concentration of cobalt acetate and cadmium iodide is 16mmol / L, and the molar ratio of cobalt acetate and cadmium iodide is 1:9 . The above methanol solution of the catalyst was mixed with the above methanol solution of propylene oxide. Add sodium acetate to the above mixed solution, and its concentration in the mixed solution is 900mmol / L. A 400W high-pressure mercury lamp is placed inside a quartz photoreactor with a hollow interlayer, and circulating water is passed into the interlayer, and the entire reactor is placed in a water tank filled with water to cool the light source. Add 4ml of methanol solution containing 1000mmol / L propylene oxide, 16mmol / L catalyst cobalt acetate and cadmium iodide, and ...

example 3

[0034] Propylene oxide (analytically pure) was mixed with methanol to prepare a methanol solution with a concentration of 250mmol / L. Mix the catalyst cobalt acetate, cadmium iodide and methanol to prepare a methanol solution with a concentration of 12mmol / L, wherein the total concentration of cobalt acetate and cadmium iodide is 12mmol / L, and the molar ratio of cobalt acetate and cadmium iodide is 1:9 . The above methanol solution of the catalyst was mixed with the above methanol solution of propylene oxide. Add sodium acetate to the above mixed solution, and its concentration in the mixed solution is 900mmol / L. A 400W high-pressure mercury lamp is placed inside a quartz photoreactor with a hollow interlayer, and circulating water is passed into the interlayer, and the entire reactor is placed in a water tank filled with water to cool the light source. Add 4ml of methanol solution containing 250mmol / L propylene oxide, 12mmol / L catalyst cobalt acetate and cadmium iodide, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com