Household biomass gasifier

A biomass and gasifier technology, which is applied to household stoves/stoves, household appliances, household heating, etc., can solve the problems of small gas production, unfavorable maintenance, and narrow use, and achieves increased gas calorific value, simplified structure, Emission reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

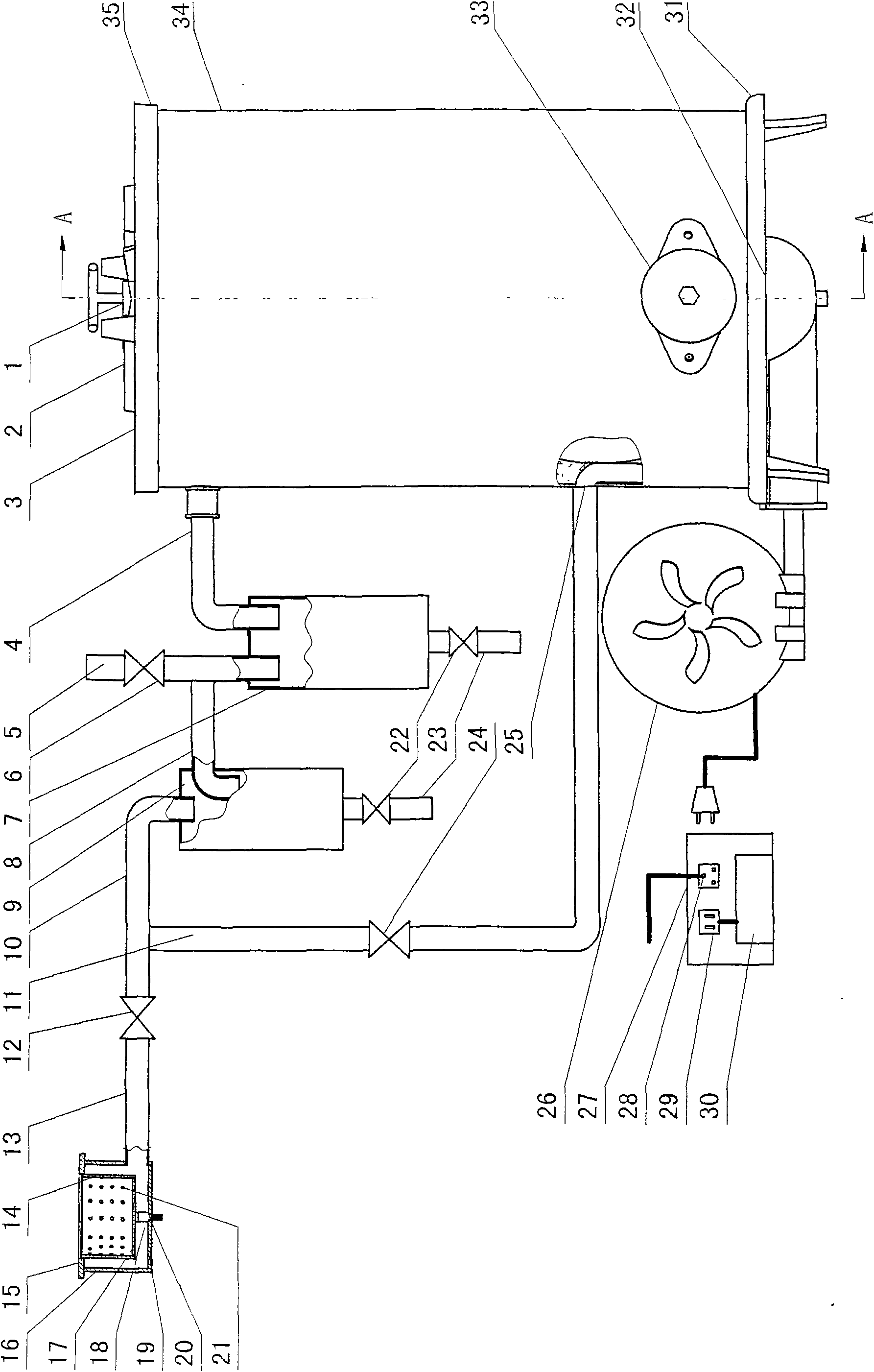

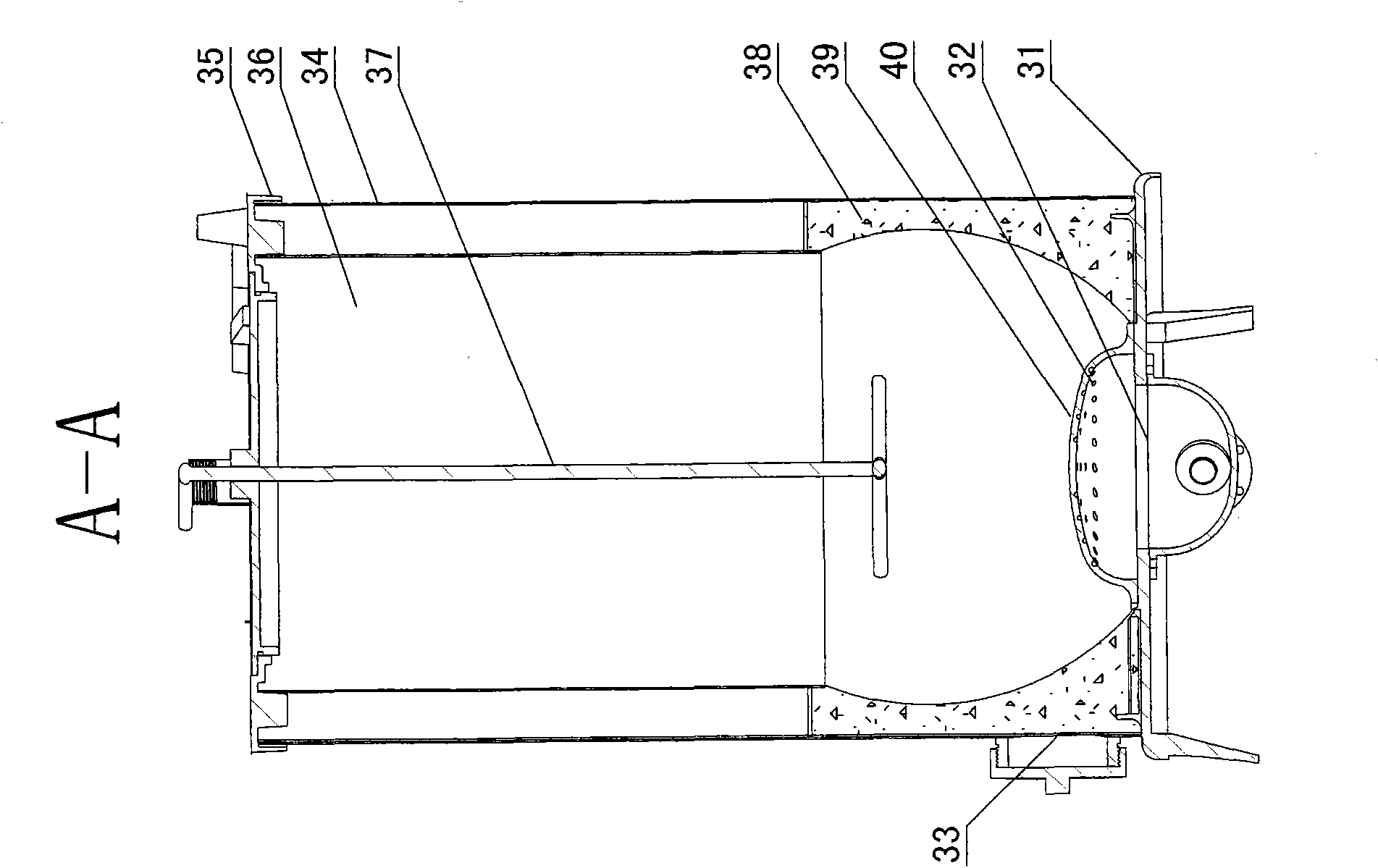

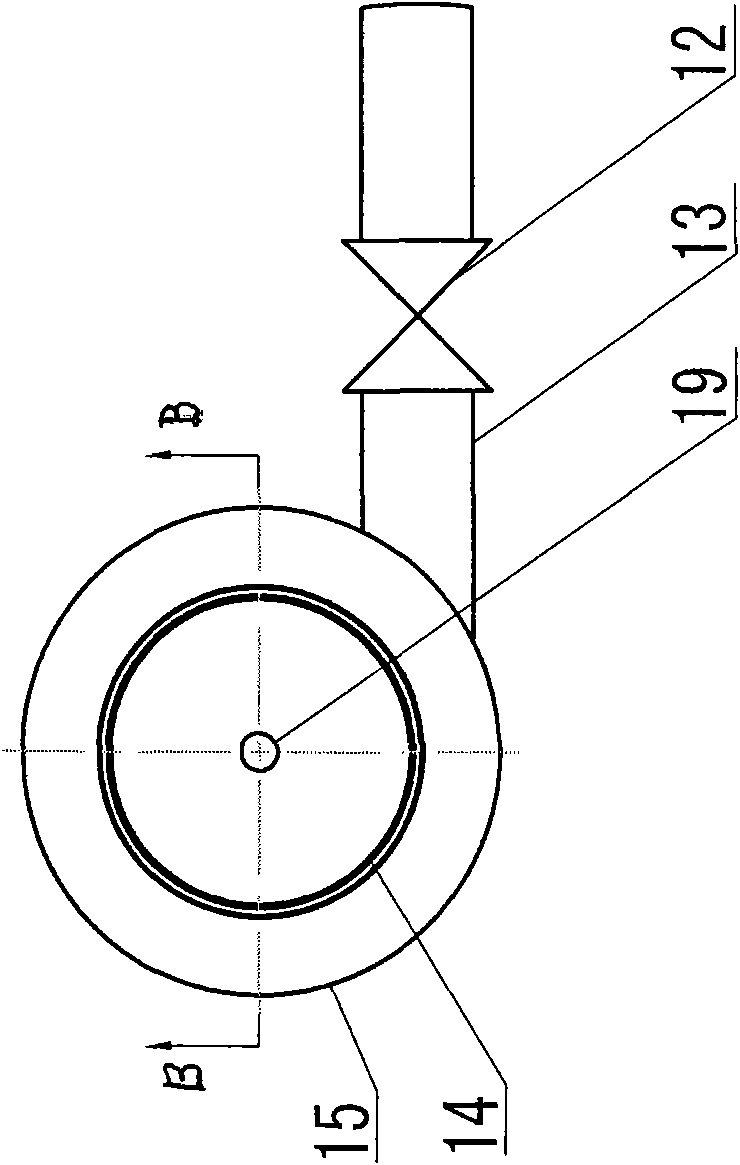

[0024] The household type biomass gasification furnace proposed by the present invention is combined with the following Figure 1-4 Further details.

[0025] As shown in the figure, there is a cylindrical fuel gasification chamber 36 in the body of the furnace. The gasification chamber is surrounded by a furnace gall formed by a high-alumina refractory cement layer 38, and a steel plate furnace shell 34 is formed outside the refractory cement layer. The upper part of the furnace body is a circular hollow cast iron roof 35 connected to the inner wall of the furnace. There is a detachable circular furnace cover 3 on the furnace roof. The furnace cover is sealed with the furnace body through two pressing parts 2 on the furnace roof. There is a circular hole 1 in the center of the furnace cover, a raw material pressing rod 37 is arranged through the circular hole, a hemispherical grate 39 is arranged at the lower part of the furnace body, and a plurality of air inlets 40 are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com