Platy LED metal substrate, platy LED light emitting device and manufacturing method thereof

A technology for metal substrates and light-emitting devices, which can be used in semiconductor/solid-state device manufacturing, electrical components, and electrical solid-state devices, etc., and can solve problems such as deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

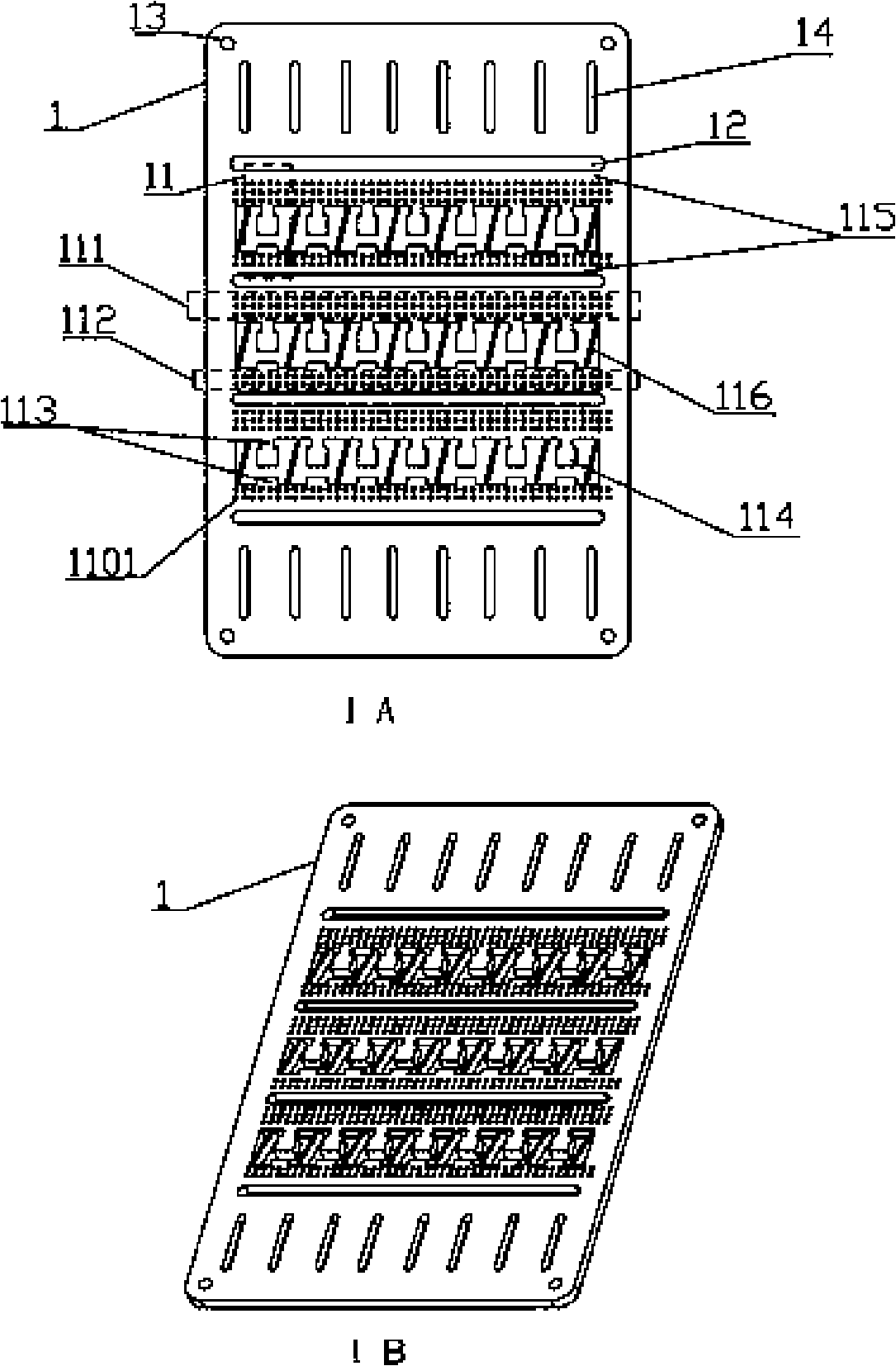

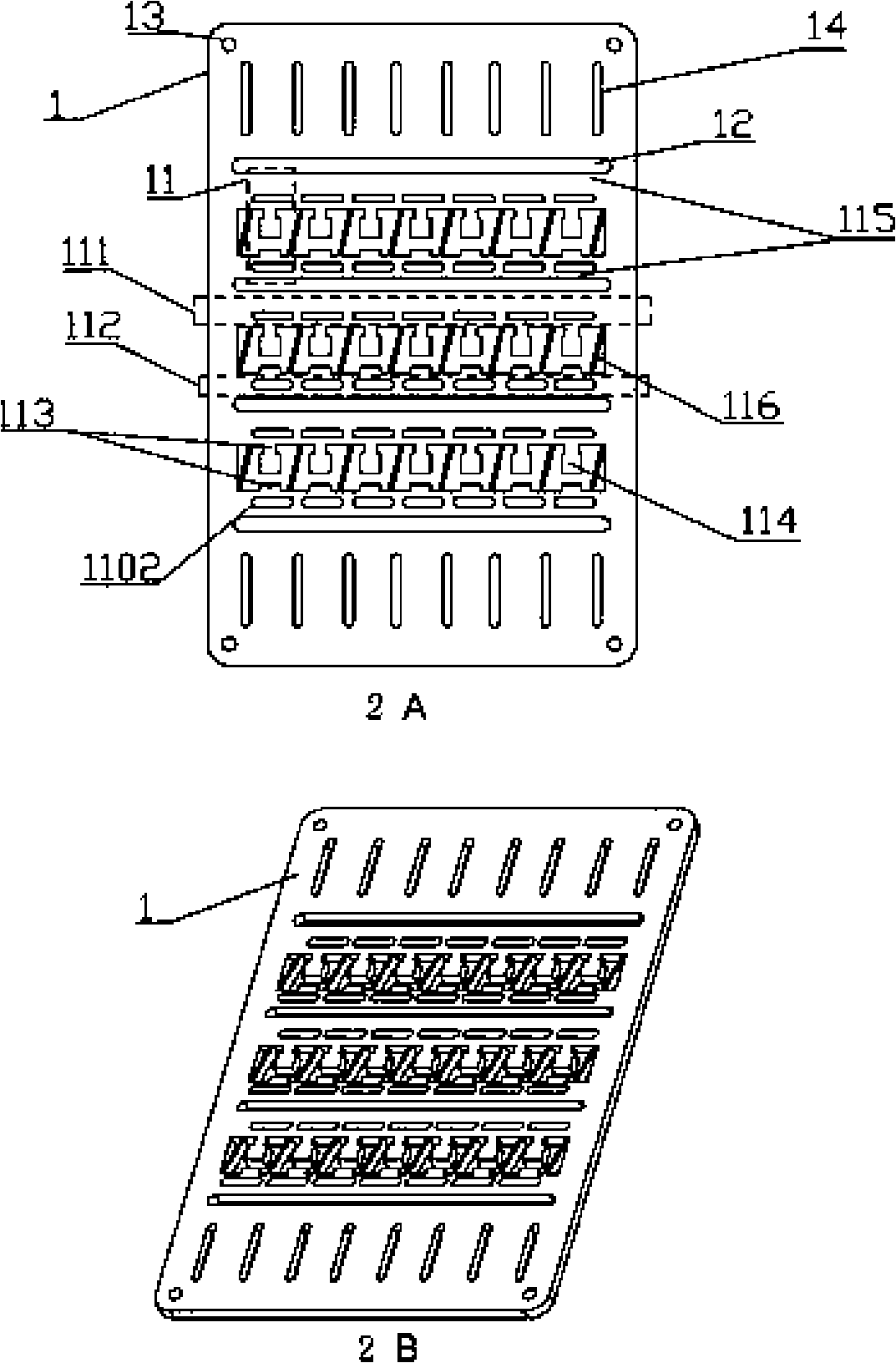

[0017] According to the above attached figure 1 And attached figure 2 , the packaging structure and manufacturing method of the chip LED lighting device of the present invention will be further described.

[0018] In this embodiment, the structure of the metal substrate 1 of the present invention includes a substrate unit array of M rows×N columns, wherein M and N are at least equal to 1 at the same time, and separation groove lines are set on both sides of each substrate unit row, totaling M+ 1, separate each substrate unit row, and N+1 cutting reference holes are respectively provided at both ends of the substrate unit row, corresponding to the side of each substrate unit row; as attached figure 1 , 2 The structure of the metal substrate 1 shown includes: an array of substrate units 11 in 3 rows×7 columns, 4 dividing groove lines 12 , 4 positioning holes 13 and 16 cutting reference holes 14 .

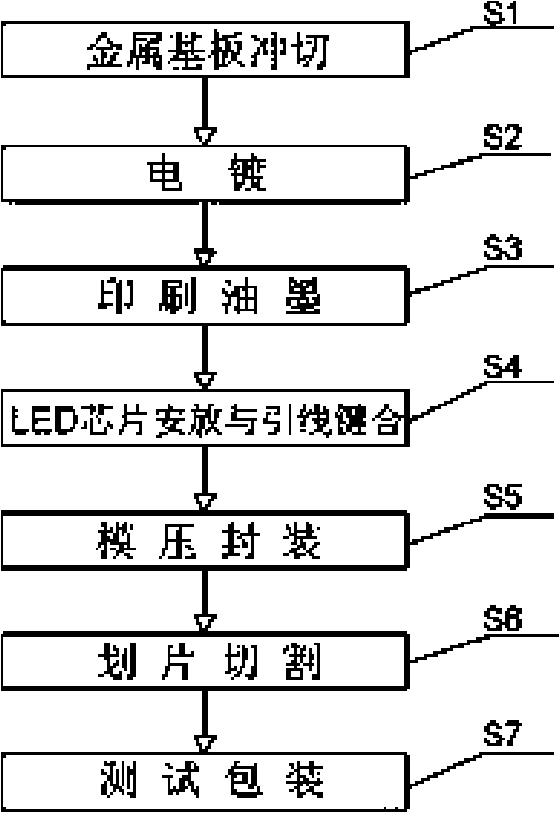

[0019] as attached figure 1 , attached figure 2 , attached Figure 5 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com