Conical phase locking carbon dioxide laser

A single-tube laser and conical technology, applied in the direction of lasers, laser components, laser components, etc., can solve the problems of processing efficiency, adverse effects on characteristics and stability, small phase relationship, poor coherence, coherent superposition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

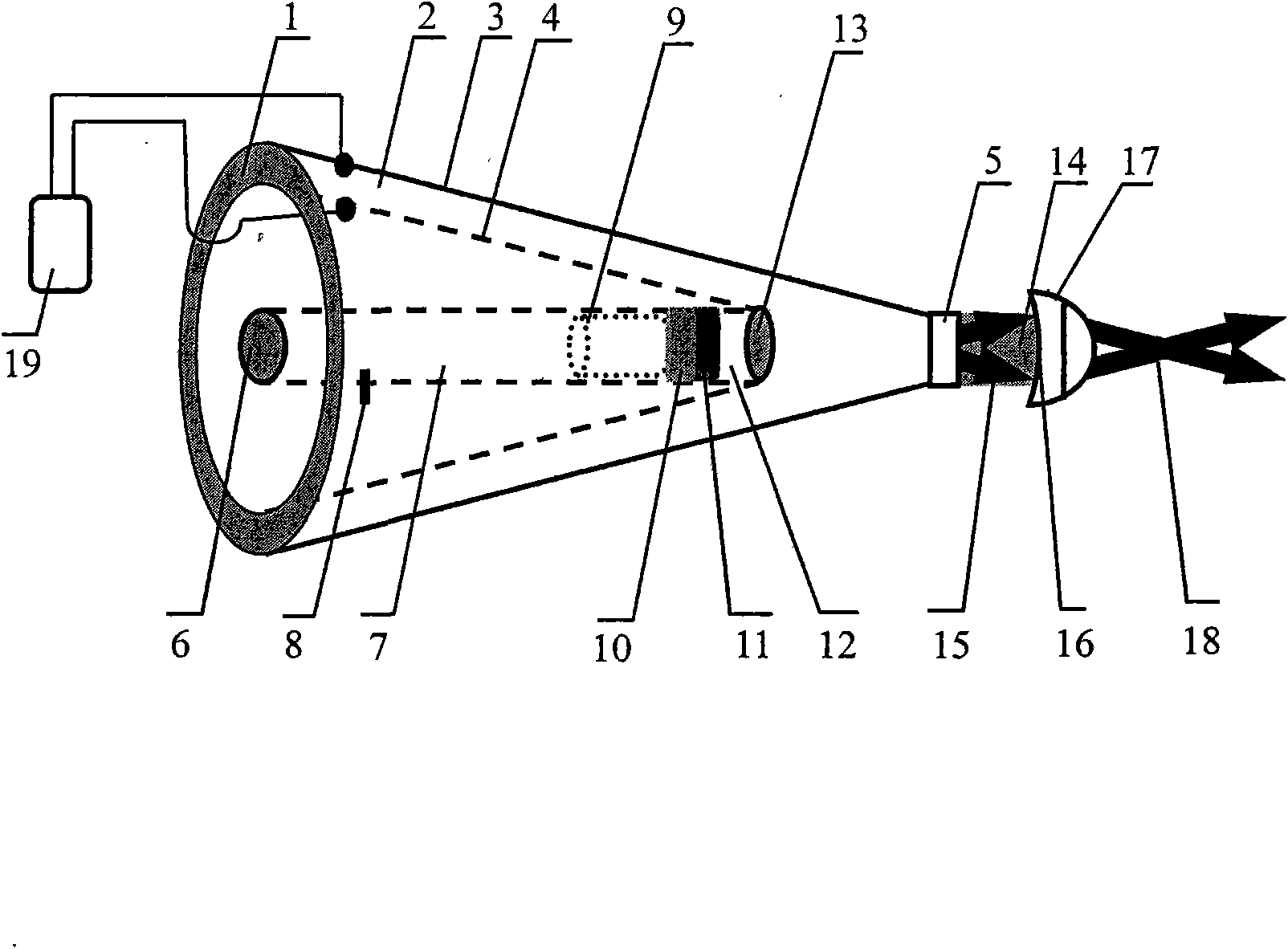

[0014] For medium power, the annular spherical concave emitting mirror 1 can be ground and polished with a quartz substrate, and the radius of curvature and surface shape are accurately checked to meet the requirements of the conventional laser cavity substrate, and then gold-coated. The output mirror 14 adopts gallium arsenide material crystal or zinc selenide crystal material as the base, and the two sides are ground into parallel planes, and the error is better within 10 ". One side is coated with a multi-layer dielectric film to achieve an emissivity of about 80%. The second The surface is coated with anti-reflection film. Generally, this kind of lens has become a commodity of various specifications. The processing of the middle-hole conical discharge tube is more complicated. The inner and outer conical tubes are respectively from large to small thick-walled round copper cylinders or other metal tubes. Lathe processing It is then combined and welded, which is convenient fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com