Dielectric ceramic composition and multilayer ceramic capacitor

A technology of dielectric ceramics and components, applied in the field of multilayer ceramic capacitors, can solve the problems of unstable operation and insufficient resistivity, and achieve the effects of stable characteristics, high resistivity and high permittivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

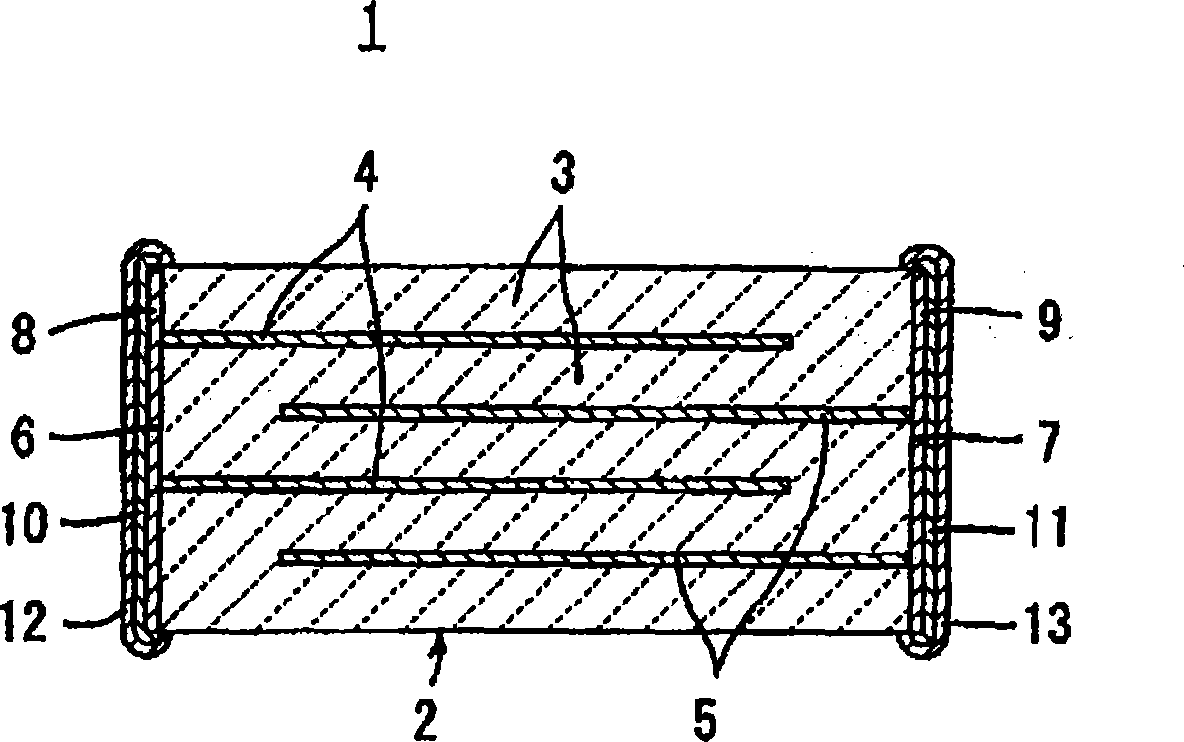

Image

Examples

experiment example 1

[0036] In this experiment example, the investigation is that, relative to the principal component (KSr 2 Nb 5 o 15 ), changing the element type and content of R and M in the subcomponents, thereby affecting the electrical characteristics. The sample numbers of the prepared samples are 1 to 35, and Table 1 shows the composition of each sample and the measurement results of electrical characteristics. It will be described in detail below.

[0037] First, as the raw material of the main component, prepare K 2CO 3 , SrCO 3 , Nb 2 o 5 , weigh these raw materials to make it a composition formula: KSr 2 Nb 5 o 15 The composition shown is mixed in a solvent with a ball mill and dried, and then synthesized by heat treatment at 1000 ° C for 2 hours, thus obtaining KSr 2 Nb 5 o 15 Composition of the main ingredient powder.

[0038] For example, with respect to 100 mole parts of the main component, the molar parts of R contained in sample numbers 1 to 35 in Table 1, the deta...

experiment example 2

[0049] In this experiment example, the investigation is that, relative to the principal component (KSr 2 Nb 5 o 15 ), in the composition of R and M containing subcomponents, a part of the K site is replaced by Na, which affects the electrical characteristics. The sample numbers of the prepared samples are 101 to 123, and Table 2 shows the composition of each sample and the measurement results of electrical characteristics. It will be described in detail below.

[0050] First, make the composition formula: (K 1-x Na x )Sr 2 Nb 5 o 15 The value of x in Table 2 is the value of x shown in sample numbers 101 to 123 in Table 2, so as the raw material of the main component, weigh K 2 CO 3 、Na 2 CO 3 , SrCO 3 , Nb 2 o 5 , mixed these raw materials with a ball mill in a solvent, dried them, and then carried out 2 hours of heat treatment synthesis at 1000 ° C, thus obtaining (K 1-x Na x )Sr 2 Nb 5 o 15 main ingredient powder.

[0051] For example, with respect to 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com