Millet beverage containing millet particles and production method thereof

A millet and beverage technology, applied in the fields of application, food preparation, food science, etc., can solve difficult stability problems such as starch precipitation and freezing, lack of millet beverage products, loss of nutrients, etc., to enrich the food product market As well as the effect of beverage market, novel product form and increasing product variety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The millet drink of the present embodiment is produced according to the following formula (in terms of one ton of product, the quality of each raw material meets relevant national or industry standards):

[0049] Millet Granules 22kg

[0050] 30kg white sugar

[0051] 15kg fructose syrup

[0052] Gelatin 0.5 kg

[0053] Gellan gum 1.3 kg

[0054] Maltodextrin 4 kg

[0055] Carrageenan 0.15 kg

[0056] Multivitamin A / D 0.2kg

[0057] Decolorized and deacidified concentrated apple juice 1.8kg

[0058] Food flavor 1.1 kg

[0059] water balance.

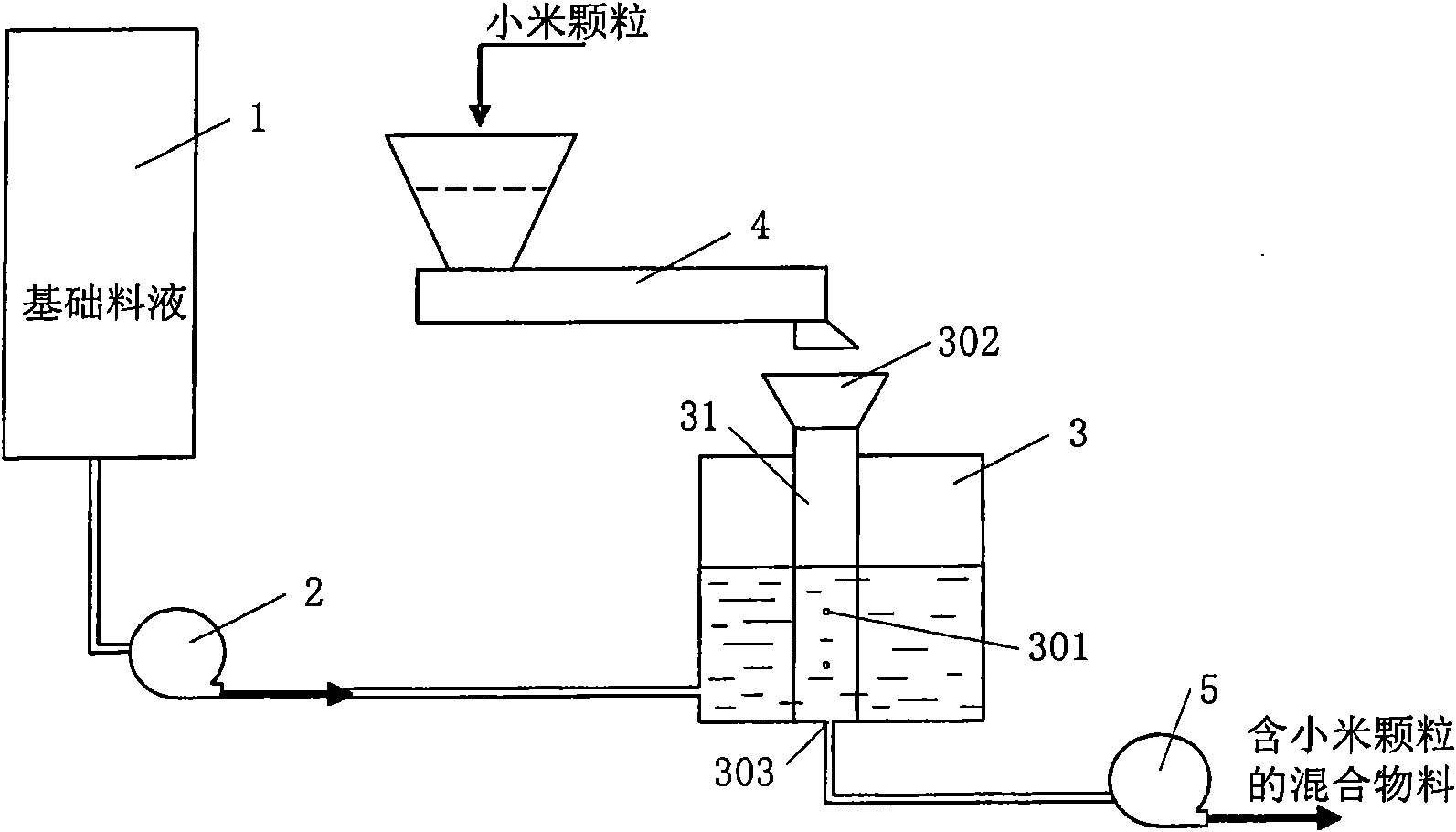

[0060] The production method of the millet beverage containing millet granules of the present embodiment can refer to figure 1 As shown, the main steps are:

[0061] 1. Preparation of basic material liquid:

[0062] Dissolving material and mixing material: fully dissolve white sugar and stabilizer (gelatin, gellan gum, maltodextrin, carrageenan) in the ingredients water (usually the temperature of the stabilizer is abou...

Embodiment 2

[0067] The millet drink of the present embodiment is produced according to the following formula (in terms of one ton of product, the quality of each raw material meets relevant national or industry standards):

[0068] Millet Granules 11kg

[0069] Millet flour 3kg

[0070] Gellan gum 1.25 kg

[0071] Xanthan gum 0.2 kg

[0072] Sodium stearoyl lactylate 0.11 kg

[0073] Compound nutrient 0.15 kg (purchased from Shanghai Licheng Company VA\VD\Fe\Zn compound nutrient)

[0074] Edible essence 1.2 kg

[0075] Milk 800kg

[0076] water balance.

[0077] In the production method of the millet beverage containing millet granules in this embodiment, batching milk is used to replace part of the batching water for compounding, and other raw materials in the formula except millet granules are mixed and homogenized properly, and the homogenization temperature is 65-70 ℃, homogenization pressure ≥ 15MPa (usually 15MPa ~ 25MPa), get the prepared basic material liquid (food flavor c...

Embodiment 3

[0080] The formula of the millet beverage containing millet granules of the present embodiment (in terms of one ton of product, each raw material meets relevant national and industry standards):

[0081] Millet Granules 52kg

[0082] corn flour 5 kg

[0083] Carrageenan 0.13 kg

[0084] Guar gum 0.4 kg

[0085] Monoglycerides 1 kg

[0086] Sucrose esters 0.5 kg

[0087] 40kg white sugar

[0088] Dietary fiber 1 kg

[0089] Food flavor 1.0 kg

[0090] Milk 900kg

[0091] water balance.

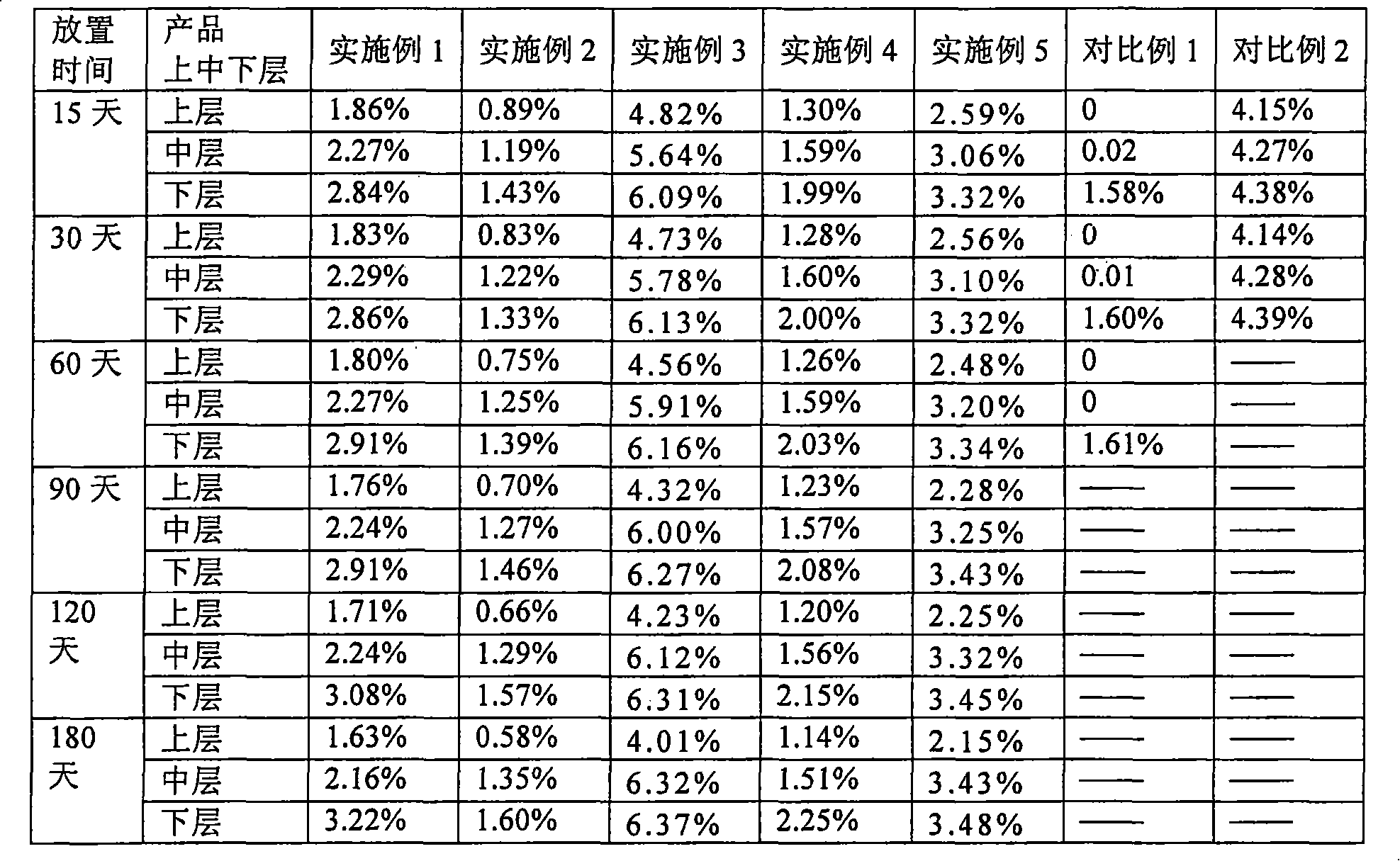

[0092] In the production method of millet beverage containing millet granules in this example, UHT sterilization (137-142°C / 4s) is used for sterilization, and then cooled to below 25°C, and low-temperature aseptic filling, and other process conditions are basically the same as in Example 2 , the product characteristics of the produced millet beverage are: the dry weight of millet granules is about 5.2%, the wet weight is about 16.6%, the sucrose content is 4.0%, and the product contain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com