Liquid crystal aligning agent, liquid crystal alignment film and liquid crystal display device

A technology of liquid crystal display element and liquid crystal alignment agent, which is applied in the field of liquid crystal alignment film, liquid crystal display element, liquid crystal alignment agent, and liquid crystal display element, and can solve problems such as poor residual characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0097] Hereinafter, although an Example demonstrates this invention concretely, this invention is not limited to these Examples. The imidization ratio, voltage retention ratio, and coatability of the imidized polymers in Examples and Comparative Examples were evaluated by the following methods.

[0098] [Measuring method of imidization rate of imidized polymer]

[0099] Put the solution of the imidized polymer into pure water, dry the obtained precipitate under reduced pressure at room temperature, dissolve it in deuterated dimethyl sulfoxide, and use tetramethylsilane as the reference substance, at room temperature determination 1 H-NMR is obtained by the following formula (ii).

[0100] Imidization rate (%) = (1-A 1 / A 2 ×α)×100--------(ii)

[0101] A 1 : Peak area of protons derived from NH group (10ppm)

[0102] A 2 : Peak area from other protons

[0103] α: In the precursor of the polymer (polyamic acid), the ratio of the number of other protons to one proton o...

Synthetic example 1

[0109] 179.34 g (0.8 mol) of 2,3,5-tricarboxycyclopentylacetic dianhydride as tetracarboxylic dianhydride and 1,3,3a,4,5,9b-hexahydro-8-methyl-5 -(tetrahydro-2,5-dioxo-3-furyl)naphtho[1,2-c]furan-1,3-dione 62.86 g (0.2 mol), terephthalamide as a diamine compound Amine 82.46g (0.7625 mol), bisaminopropyl tetramethyldisiloxane 24.85g (0.1 mol), 4,4'-diaminodiphenylmethane 19.83g (0.1 mol) and 4-(4'- 13.15 g (0.03 mol) of trifluoromethoxybenzoyloxy)cyclohexyl-3,5-diaminobenzoate and 1.40 g (0.015 mol) of aniline as a monoamine were dissolved in 1,550 g of N-methyl - In 2-pyrrolidone, react at 60° C. for 6 hours to obtain a polyamic acid solution with a solution viscosity of 60 mPa·s. 1,920 g of N-methyl-2-pyrrolidone was dissolved in the obtained polyamic acid, 237.4 g of pyridine and 306.4 g of acetic anhydride were added, and dehydration ring closure was performed at 110° C. for 4 hours. After the imidization reaction, the solvent in the system is replaced with a new N-methyl...

Synthetic example 2

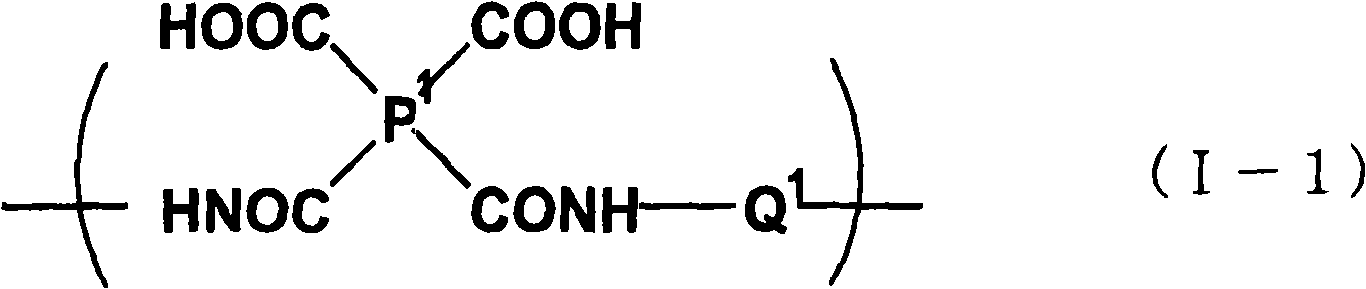

[0111] 112.09 g (0.50 moles) of 2,3,5-tricarboxycyclopentylacetic dianhydride as tetracarboxylic dianhydride and 1,3,3a,4,5,9b-hexahydro-8-methyl-5 -(tetrahydro-2,5-dioxo-3-furyl)naphtho[1,2-c]furan-1,3-dione 157.15 g (0.50 mol), terephthalamide as a diamine compound 90.03 g (0.8325 mol) of amine, 24.85 g (0.10 mol) of bisaminopropyltetramethyldisiloxane, 29.69 g (0.06 mol) of a diamine compound represented by the above formula (23), and 1.40 g of aniline as a monoamine g (0.015 mol) was dissolved in 970 g of N-methyl-2-pyrrolidone and reacted at 60° C. for 6 hours to obtain a polyamic acid having a solution viscosity of 55 mPa·s. 2800 g of N-methyl-2-pyrrolidone was dissolved in the obtained polyamic acid, 158.2 g of pyridine and 204.2 g of acetic anhydride were added, and dehydration ring closure was performed at 110° C. for 4 hours. After the imidization reaction, the solvent in the system is replaced with a new N-methyl-2-pyrrolidone (by this operation, pyridine and aceti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solution viscosity | aaaaa | aaaaa |

| Solution viscosity | aaaaa | aaaaa |

| Solution viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com